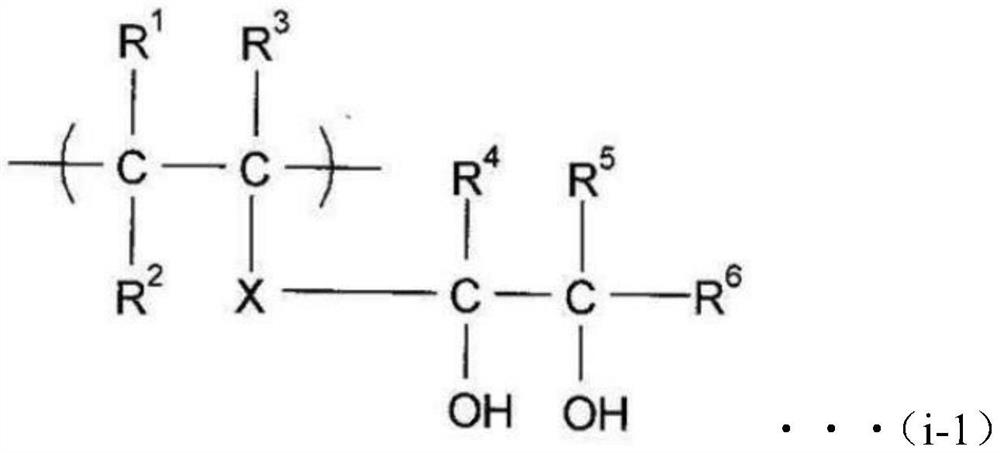

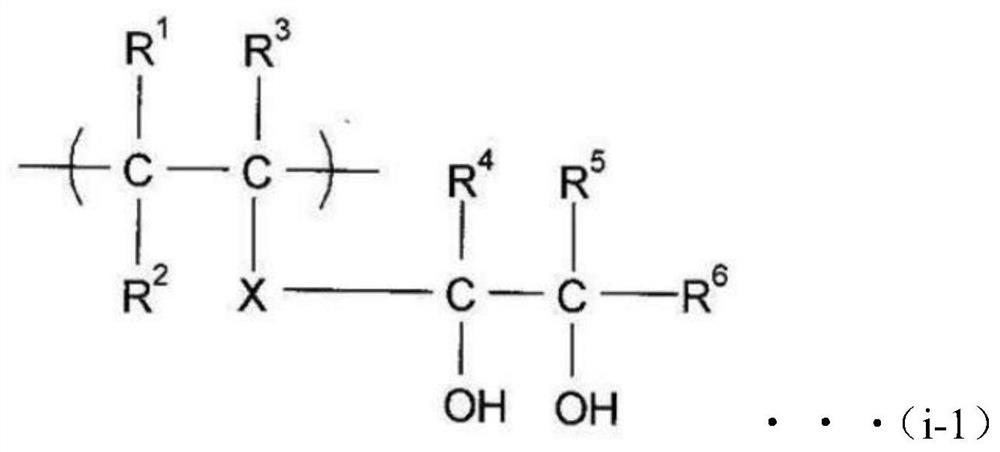

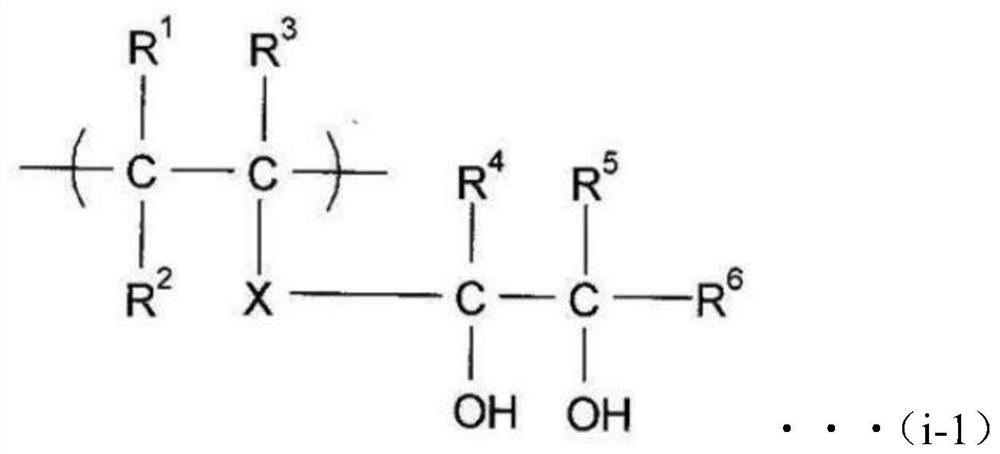

Ethylene-vinyl alcohol based copolymer resin composition, multilayer structural body and packaging body

A resin composition, vinyl alcohol technology, used in transportation and packaging, synthetic resin layered products, packaging, etc., can solve problems such as damage, pinhole generation, EVOH layer rupture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[1124] Hereinafter, the present invention will be described more concretely with examples and comparative examples shown in the following tables, but the present invention is not limited to the following examples unless the gist is exceeded. In addition, in an example, "part" means a weight basis.

[1125] >

Embodiment I-1

[1127] 〔Manufacture of EVOH resin composition〕

[1128] As EVOH (A), an ethylene-vinyl alcohol copolymer containing EVOH (a1) [ethylene structural unit content 29 mol%, saponification degree 99.7 mol%, MFR 3.8g / 10min (210°C, load 2160g)] was used as EVOH (A). Sodium acetate (b1) as pellets of EVOH (a1) of acetic acid and / or its salt (B). In addition, stearic acid (c1) was used as the aliphatic carboxylic acid (C), and zinc stearate (d1) was used as the aliphatic carboxylic acid metal salt (D).

[1129] In addition, as the content of each component, 432 ppm of acetic acid in terms of acetate ion was used relative to the total content of EVOH (a1), sodium acetate (b1), stearic acid (c1), and zinc stearate (d1). For sodium (b1), 1.0 ppm of stearic acid in terms of carboxylate ions was used relative to the total content of EVOH (a1), sodium acetate (b1), stearic acid (c1), and zinc stearate (d1) (c1), zinc stearate (d1) at 20 ppm in terms of metal ions relative to the total cont...

Embodiment I-2

[1177] Using stearic acid (c1) at 2.4 ppm in terms of carboxylate ions relative to the total content of EVOH (a1), sodium acetate (b1), stearic acid (c1), and zinc stearate (d1), use Zinc stearate (d1) is 50 ppm in terms of metal ions relative to the total content of EVOH (a1), sodium acetate (b1), stearic acid (c1), and zinc stearate (d1), and other Otherwise, an EVOH resin composition and a multilayer structure were produced in the same manner as in Example I-1. The obtained EVOH resin composition and multilayer structure were evaluated in the same manner as in Example I-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com