Composite bait wire drawing powder and preparation method thereof

A wire drawing powder and bait technology, applied in fishing, fishing accessories, applications, etc., can solve the problems of increasing the ineffective components of bait, unfavorable for fishermen, limited pulling force and adhesion, etc., to achieve unique flavor, low manufacturing cost, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

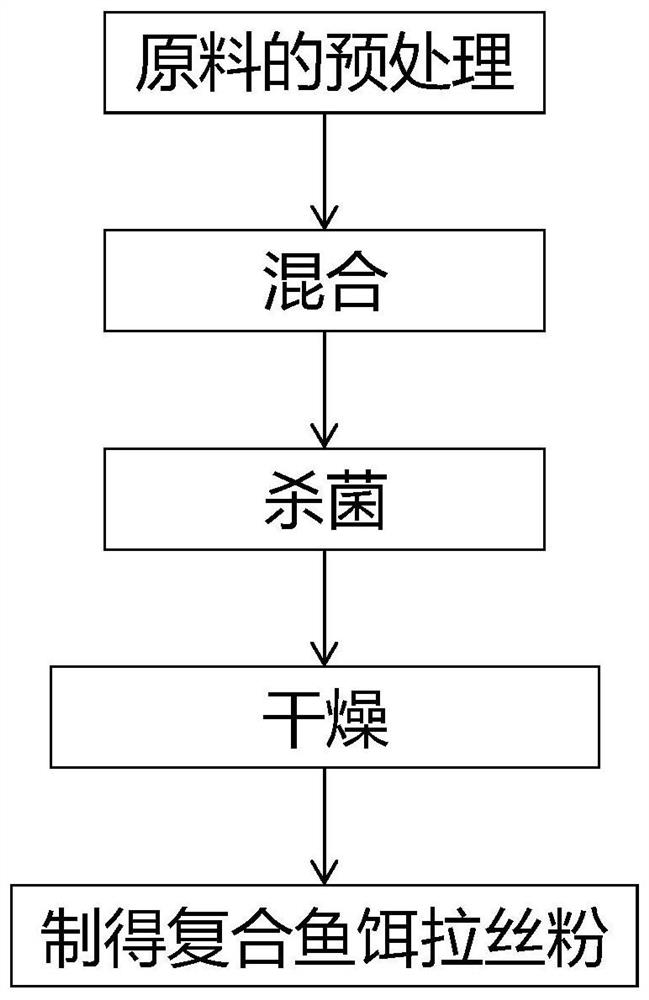

[0033] A preparation method of composite fishing bait drawing powder, comprising the steps of:

[0034] S1. Pretreatment of raw materials: After washing and removing impurities from the Sapphire fruit, Sangria sinensis fruit, Kidney beans, and Bitter melon seeds, and then freeze-drying, The water content of the beans and the bitter gourd seeds is between 5%, and after being ground and passed through a 100-mesh sieve, they can be made into powdery raw materials;

[0035] S2. Mixing: in parts by weight, accurately weigh the powdered raw materials prepared in step S1, mix 70 parts of Sapphire fruit powder, 20 parts of sea mulberry fruit powder, 80 parts of soluble sugar, 15 parts of flower kidney bean powder, and 10 parts of bitter gourd The seed powder, 5 parts of vegetable protein powder and 5 parts of coagulant are mixed evenly to prepare a mixture;

[0036] S3. Sterilization: Put the mixture prepared in step S2 into an ozone sterilizer for ozone sterilization treatment. The ...

Embodiment 2

[0039] A preparation method of composite fishing bait drawing powder, comprising the steps of:

[0040]S1. Pretreatment of raw materials: After washing and removing impurities from the Sapphire fruit, Sangria sinensis fruit, Kidney beans, and Bitter melon seeds, and then freeze-drying, The water content of the beans and the bitter gourd seeds is between 7%, and after grinding and passing through a 100-mesh sieve, they can be made into powdery raw materials;

[0041] S2. Mixing: in parts by weight, accurately weigh the powdered raw materials prepared in step S1, mix 80 parts of Sapphire fruit powder, 25 parts of sea mulberry fruit powder, 85 parts of soluble sugar, 18 parts of flower kidney bean powder, and 13 parts of bitter melon The seed powder, 8 parts of vegetable protein powder and 7 parts of coagulant are mixed evenly to prepare a mixture;

[0042] S3. Sterilization: Put the mixture prepared in step S2 into an ozone sterilizer for ozone sterilization treatment. The ozon...

Embodiment 3

[0045] A preparation method of composite fishing bait drawing powder, comprising the steps of:

[0046] S1. Pretreatment of raw materials: After washing and removing impurities from the Sapphire fruit, Sangria sinensis fruit, Kidney beans, and Bitter melon seeds, and then freeze-drying, The water content of the beans and the bitter gourd seeds is between 9%, and after grinding and passing through a 100-mesh sieve, they can be made into powdery raw materials;

[0047] S2. Mixing: in parts by weight, accurately weigh the powdered raw materials prepared in step S1, mix 90 parts of Sapphire fruit powder, 30 parts of sea mulberry fruit powder, 90 parts of soluble sugar, 20 parts of flower kidney bean powder, and 15 parts of bitter gourd Seed powder, 10 parts of vegetable protein powder and 10 parts of coagulant are mixed evenly to prepare a mixture;

[0048] S3. Sterilization: Put the mixture prepared in step S2 into an ozone sterilizer for ozone sterilization treatment. The ozone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com