Selenium-rich potato slice processing technology

A technology of selenium-enriched potatoes and processing technology, which is applied to the peeling of vegetables or fruits, the function of food ingredients, food science, etc. The effect of less waste, less discoloration, and high quality of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

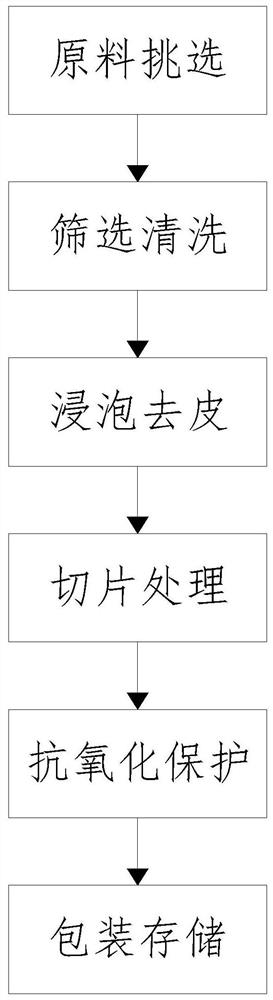

[0035] see figure 1 Shown, a kind of selenium-enriched potato slice processing technology, the slice processing technology of described selenium-enriched potato comprises the steps:

[0036] (1) Raw material selection, preliminarily screen the potatoes to be treated, send the selected raw materials into the hopper, convey the raw materials through a belt conveyor, weigh the raw materials, and select at the same time to remove the moldy spotted potato pieces and Rot block part;

[0037] (2) Screening and cleaning, the potatoes are removed from sand and impurities by a dry cleaner, and then sent to a drum cleaner for cleaning;

[0038] (3) Soak and peel the potatoes, soak the cleaned potatoes again, put the soaked potatoes with smooth surface into the steam peeling machine in batches, and heat them under the pressure of 5mpa to 6mpa for 20s to make blisters on the surface of the potatoes, and then wash them with running water rinse the skin;

[0039] (4) slicing process, send...

Embodiment 2

[0053] see figure 1 Shown, a kind of selenium-enriched potato slice processing technology, the slice processing technology of described selenium-enriched potato comprises the steps:

[0054] (1) Selection of raw materials: Preliminary screening of the potatoes to be processed, feeding the selected raw materials into the hopper, transporting them through a belt conveyor, weighing the raw materials, and selecting at the same time, removing the moldy spotted potato pieces and Rot block part;

[0055] (2) Screening and cleaning, the potatoes are removed from sand and impurities by a dry cleaner, and then sent to a drum cleaner for cleaning;

[0056] (3) Soak and peel the potatoes, soak the cleaned potatoes again, load the soaked potatoes with smooth surface into the steam peeling machine in batches, heat under the pressure of 5mpa~6mpa for 20s to make blisters on the surface of the potatoes, and then wash them with running water rinse the skin;

[0057] (4) slicing process, sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com