A kind of method and application of preparing heavy metal adsorbent by using blast furnace slag

A technology of blast furnace slag and adsorbent, which is applied in the field of heavy metal sewage treatment, can solve the problems of metal ions not being recovered and reused, poor application effect, and low adsorption rate of heavy metal ions, and achieve low cost, good adsorption rate, and raw material cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

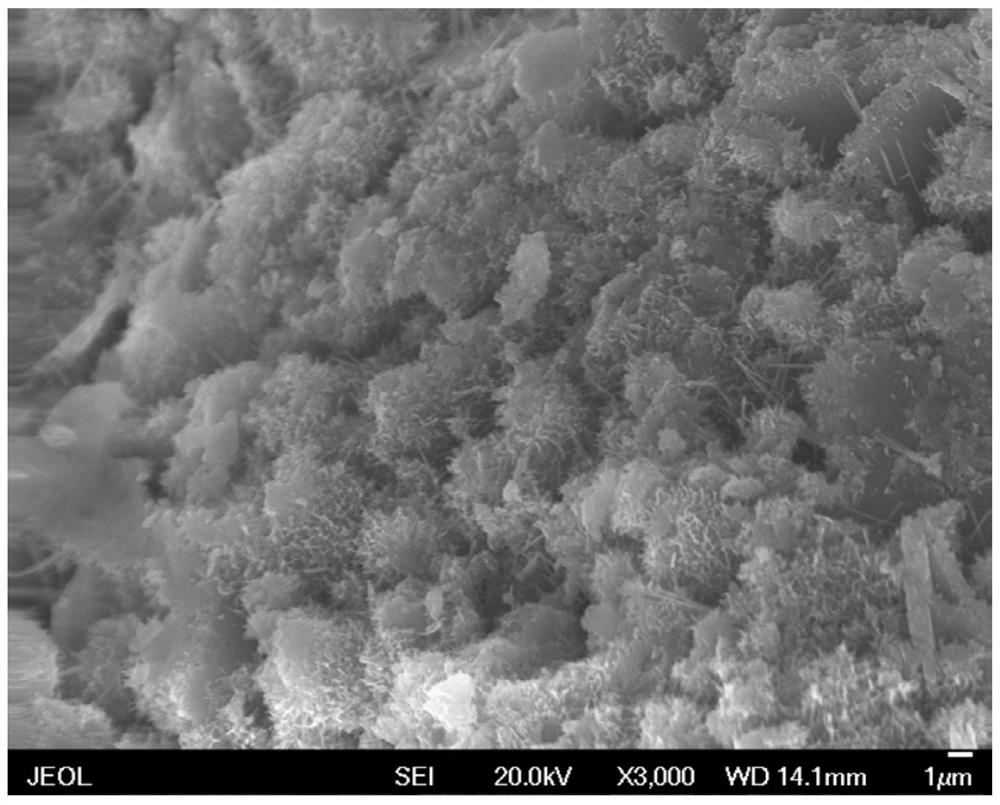

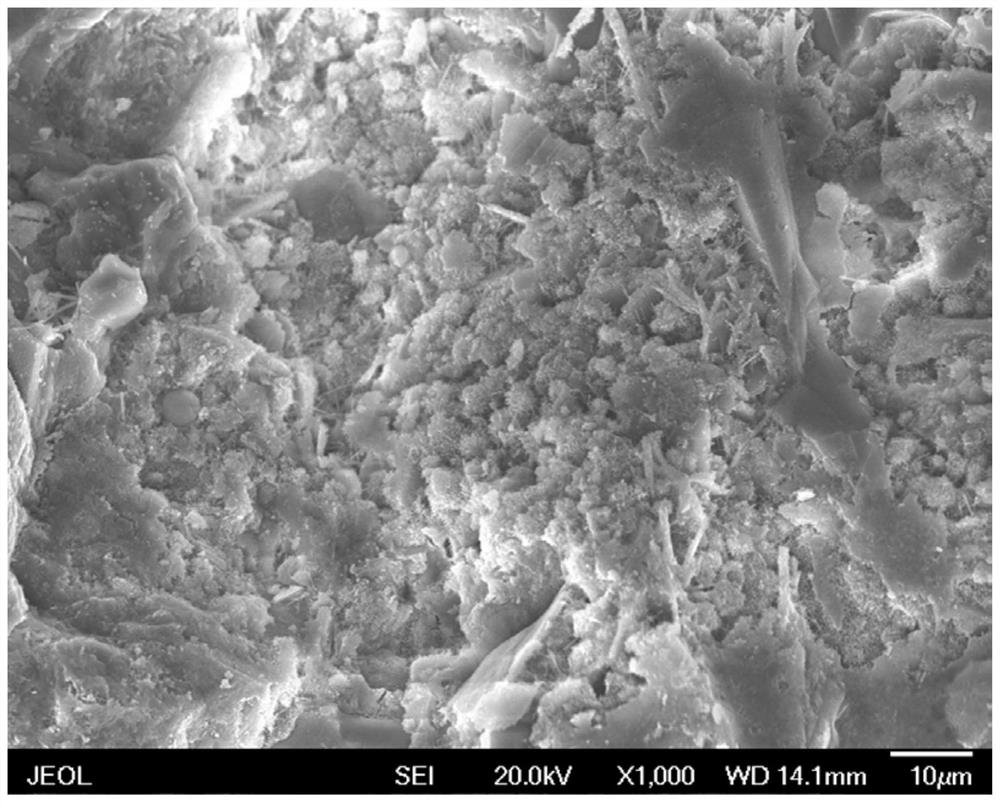

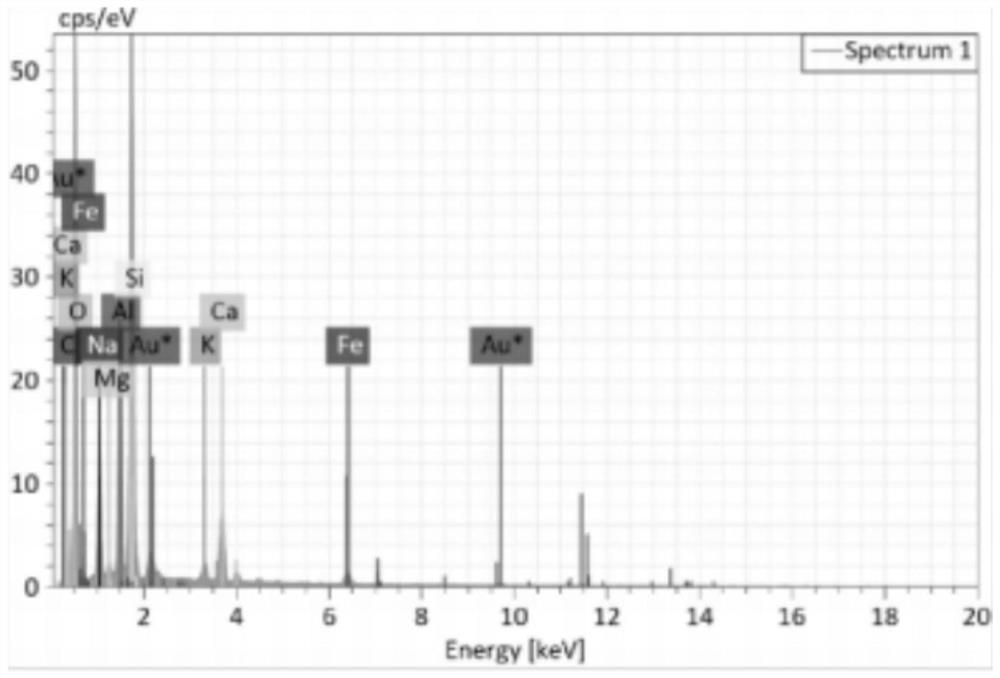

Image

Examples

preparation example 1

[0029] S1: Immerse 100 parts of blast furnace slag in 200 parts of water for 20 minutes, filter, dry, take out and place in a ball mill, grind to a particle size of 120 mesh, for use;

[0030] S2: Mix the ground product obtained in step S1 with a sodium hydroxide solution with a concentration of 10 mol / L at a weight ratio of 1:6, heat up to 60° C., then keep the constant temperature stirring for 1.5 hours, and finally cool and filter with suction to retain the filtrate. Denoted as solution 1, the filter residue was washed with water 4 times to a constant weight, dried for use and denoted as solid 1; this step is to separate aluminum and silicon from blast furnace slag with alkaline solution.

[0031] S3: adding the hydrochloric acid solution with a concentration of 4mol / L in solution 1 to adjust pH to 8, then suction filtration, and retaining the filtrate as solution 2 for subsequent use; washing the filter residue with water 3 times, then adding to the sodium hydroxide solutio...

preparation example 2

[0037] The rest are the same as in Preparation Example 1, except that in Step S4, the suspension 1 is prepared from the solid 1 and the water in a weight ratio of 1:4.

preparation example 3

[0039] The rest are the same as in Preparation Example 1, except that in step S4, suspension 2 is prepared by suspension 1 and solution 3 in a weight ratio of 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com