Preparation method of niobium-doped modified stannic oxide quantum dot visible light catalytic material

A technology of tin dioxide and catalytic materials, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of low utilization efficiency of visible light and high preparation cost, and achieve Excellent photocatalytic performance, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A method for preparing a niobium-doped modified tin dioxide quantum dot visible light catalytic material, comprising the following steps:

[0028] S1, tin protochloride dihydrate (SnCl 2 2H 2 O) and thiourea (CH 4 N 2 S) mixing and dissolving in deionized water, stirring at 24°C-27°C for 12-36h to obtain a tin dioxide quantum dot solution;

[0029] S2, get ammonium niobate oxalate hydrate (C 2 h 2 o 4 ·x(NH 3 )·x(Nb)) is dissolved in deionized water to form a niobium solution with a niobium concentration of 0.2-0.5mol / L;

[0030] S3. Mix the obtained tin dioxide quantum dot solution and niobium solution, and perform hydrothermal treatment at 160-180° C. for 5-7 hours to obtain niobium-doped tin dioxide quantum dots.

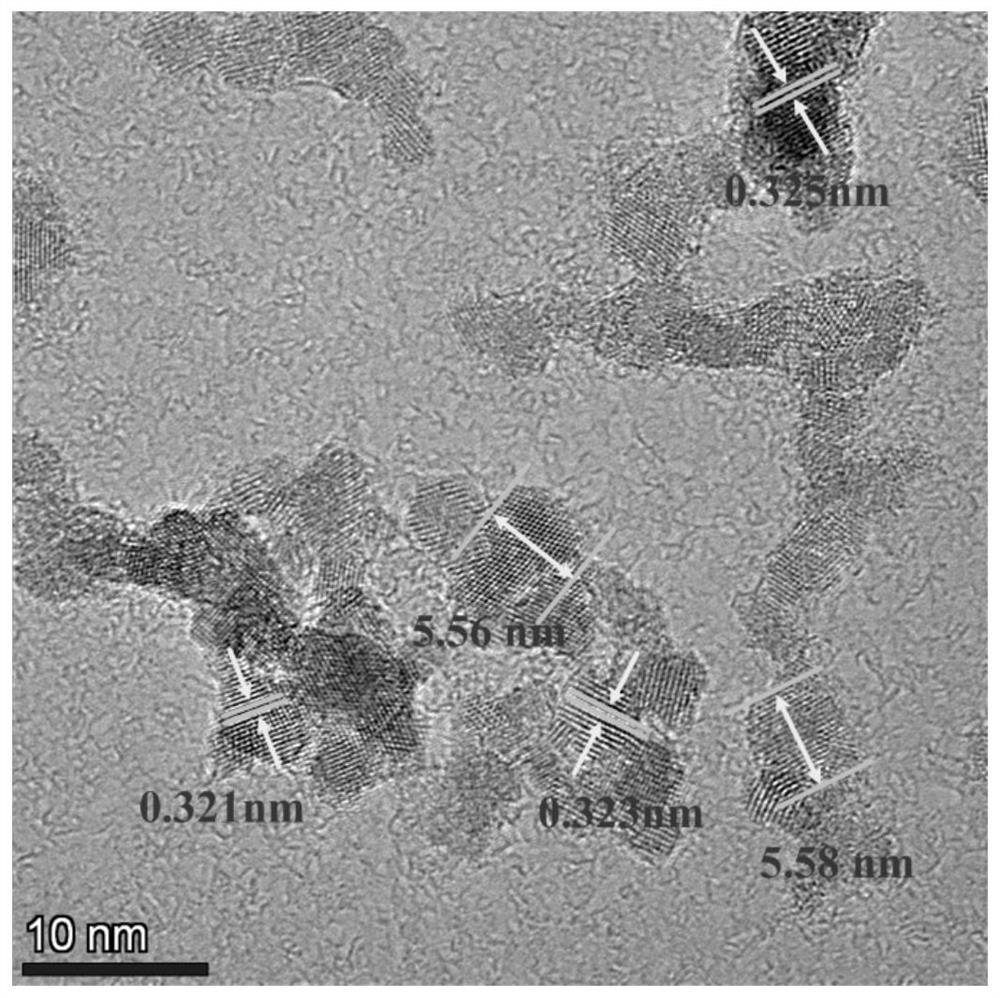

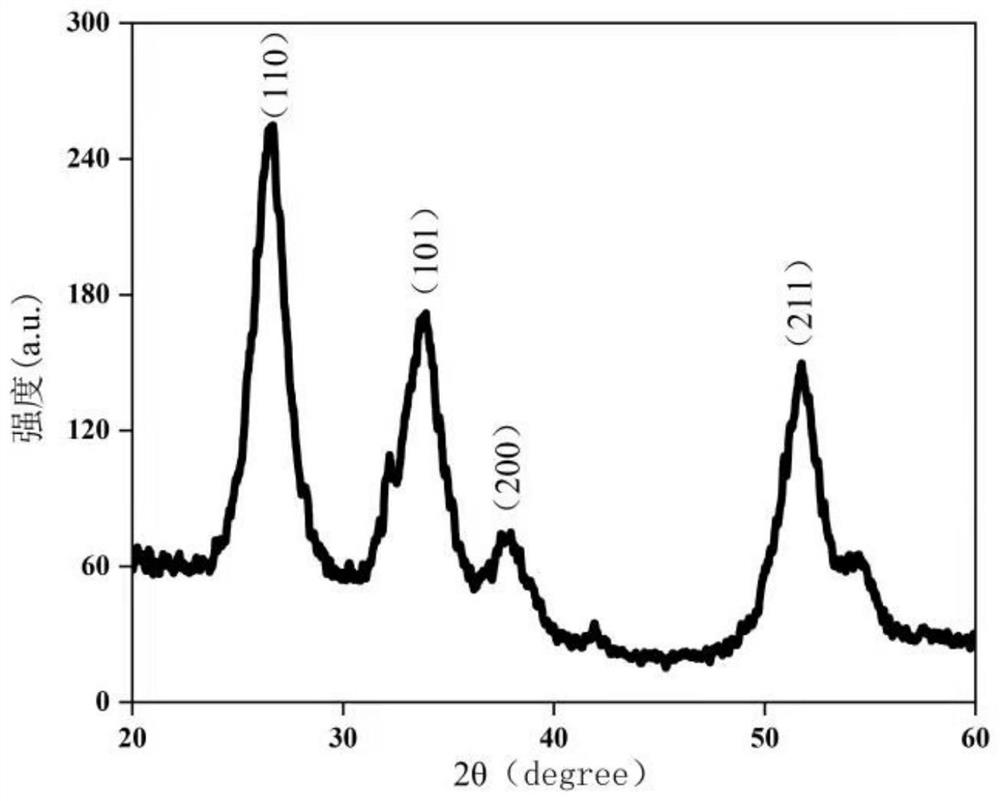

[0031] Preferably, in step S1, the mass ratio of stannous chloride dihydrate to thiourea is (25-32):1, and the concentration of the tin dioxide quantum dot solution is 0.17-0.22 mol / L. In step S3, the particle size of the niobium-doped tin dioxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com