Sewage treatment process and sewage treatment device

A sewage treatment device and technology for sewage treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, return water treatment, etc., can solve the problem that the effect of denitrification and phosphorus removal is difficult to be further improved, and the biological metabolism function and activity decline. , the phosphorus removal effect is not satisfactory, etc., to reduce the sludge SVI, improve the microbial activity, and prolong the sludge age.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

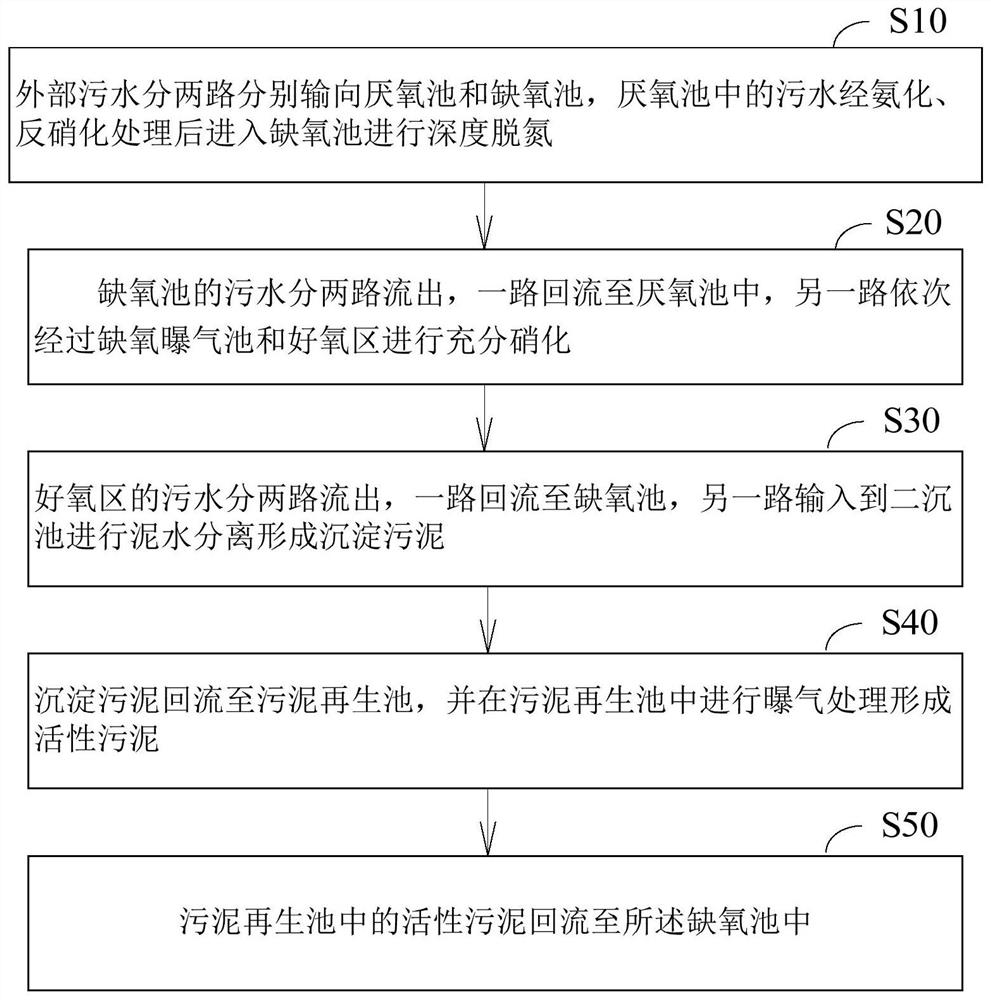

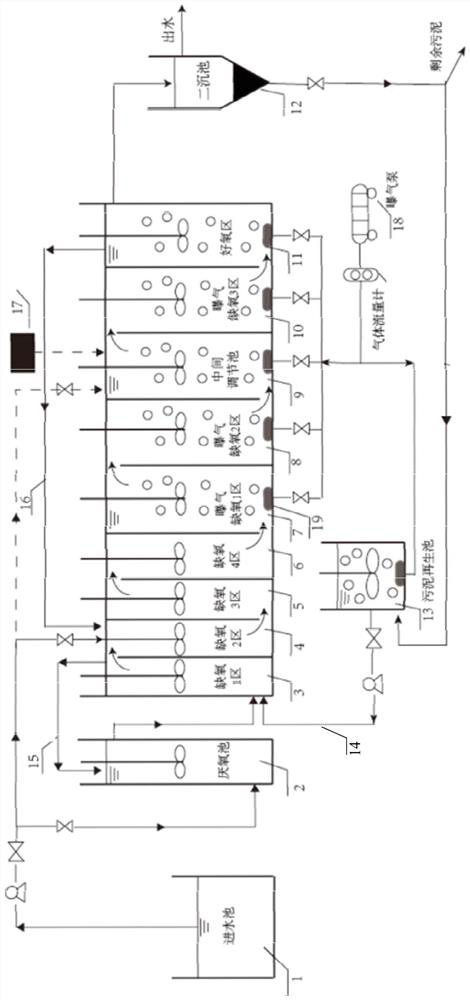

[0038] The present invention proposes a sewage treatment process, with reference to figure 1 , including the following steps:

[0039] S10. The external sewage is sent to the anaerobic pool and the anoxic pool respectively in two ways. The sewage in the anaerobic pool is treated by ammonification and denitrification and enters the anoxic pool for deep denitrification.

[0040] The sewage enters the anoxic pond after ammonification, denitrification and phosphorus release treatment in the anaerobic pond; the organic matter degradation, denitrification, deep denitrification and phosphorus release treatment are carried out in the sewage in the anoxic pond; part of the sewage in the anoxic pond is refluxed into the anaerobic tank. In this step, the anaerobic tank refers to a non-aerobic tank, and the dissolved oxygen concentration is generally less than 0.2mg / L. Microorganisms absorb organic matter and release phosphorus in this tank. Anoxic pool refers to a non-oxygenated pool, ...

Embodiment 2

[0048] This embodiment is an improvement based on embodiment 1, with reference to figure 1 , in step S20, said another road successively passes through the anoxic aeration tank and the aerobic zone to carry out sufficient nitrification and also includes the following steps: S21. The sewage in the anoxic aeration tank enters the intermediate adjustment tank, and the external sewage enters from the third road Enter the intermediate adjustment tank, and the sewage in the intermediate adjustment tank enters the aerobic zone after conditioning treatment. In this step, the external sewage is rich in organic matter, which can be directly input into the intermediate adjustment tank to provide carbon sources for the activities of microorganisms in the tank and the aerobic tank, which can further save the input of external carbon sources.

Embodiment 3

[0050] In step S20, the other path sequentially passes through the anoxic aeration tank and the aerobic zone to carry out sufficient nitrification, and further includes the following steps: the other sewage from the anoxic tank passes through the aeration and anoxic zone one and the anoxic zone of the anoxic aeration tank in turn. After aeration and anoxic zone two, it enters the intermediate adjustment tank, and the sewage in the intermediate adjustment tank flows into the aerobic zone through the aeration and anoxic zone three. In this step, the external sewage is rich in ammonia nitrogen, and the three aeration and anoxic zones can be set to perform deep denitrification of the newly added sewage, further improving the denitrification efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com