Split-phase desulfurization method and device based on ozone oxidation

An ozone oxidation and oxidative desulfurization technology, applied in the petroleum industry, multi-stage series refining process treatment, hydrocarbon oil treatment, etc., can solve problems such as excessive oxidation of fuel oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

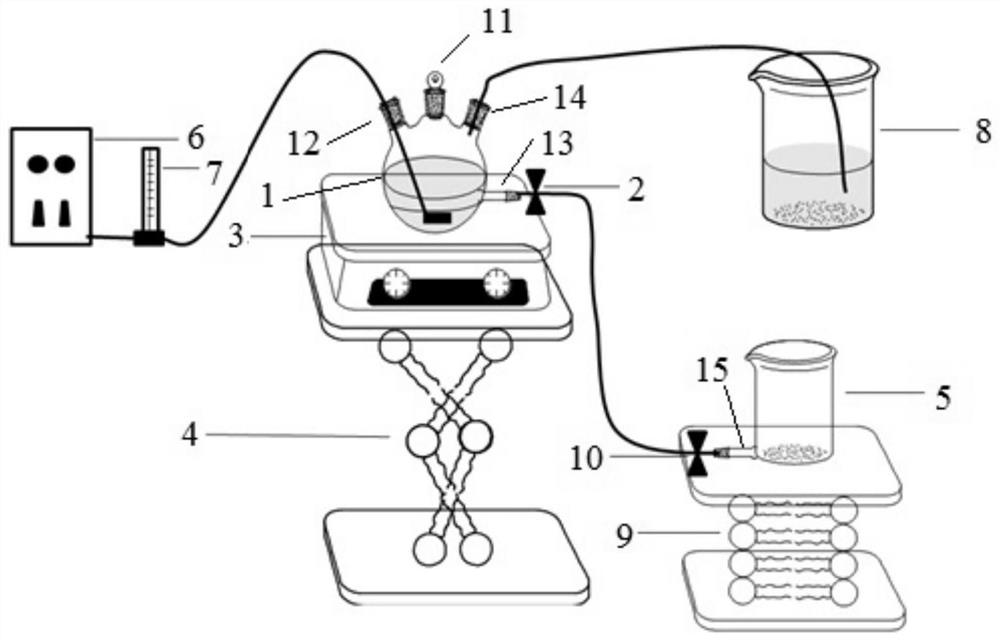

[0048] An embodiment of the present invention provides a phase separation desulfurization device based on ozone oxidation, including: a reactor 1, an agitator 3, a first lifting platform 4, a collector 5, a second lifting platform 9, an ozone generator 6, and an ozone absorber 8. Rotameter 7, first valve 2 and second valve 10.

[0049] The reactor 1 is provided with an air inlet 12, an air outlet 14, a liquid inlet 11 and a liquid outlet 13, which are used to extract and separate the oil product to be desulfurized into an oil phase and an extraction phase, and perform oxidative desulfurization on the extraction phase; The reactor 1 is provided with a stirrer 3 for stirring the solution in the reactor 1 evenly; the first lifting platform 4 is arranged below the above-mentioned reactor 1 for adjusting the height of the reactor 1; the collector 5 A collection port 15 is provided, and the above-mentioned collection port 15 communicates with the liquid outlet 13 of the above-mentio...

Embodiment 2

[0061] An embodiment of the present invention provides a phase-separated desulfurization method based on ozone oxidation, that is, the phase-separated desulfurization device based on ozone oxidation in Example 1 is used, and the method includes the following steps:

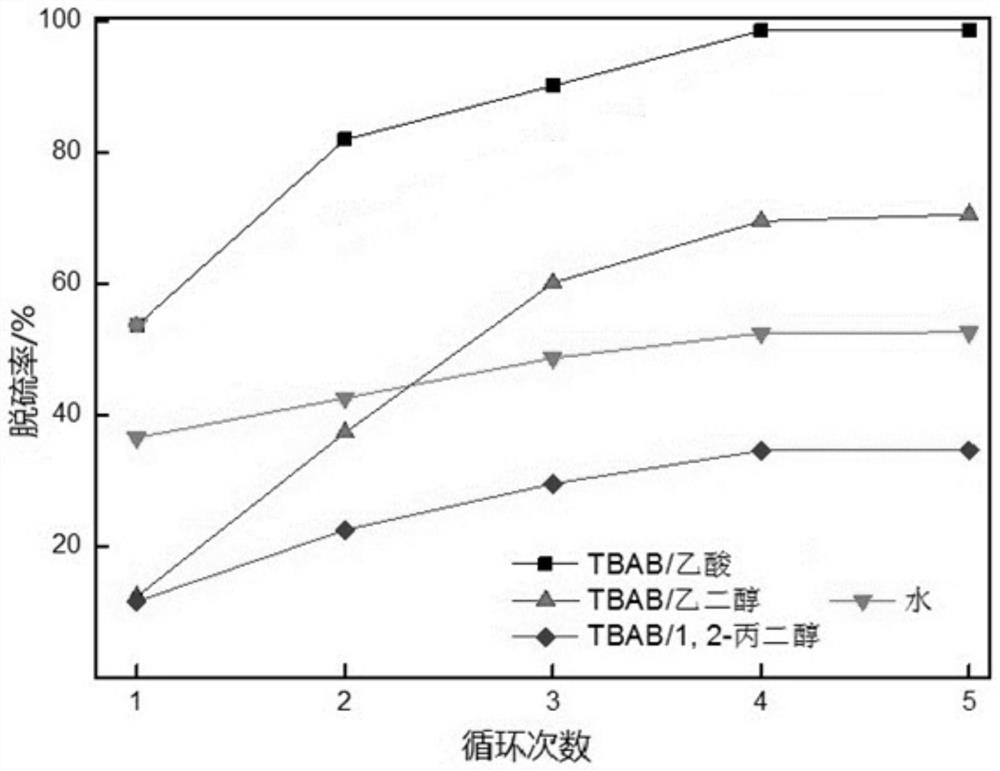

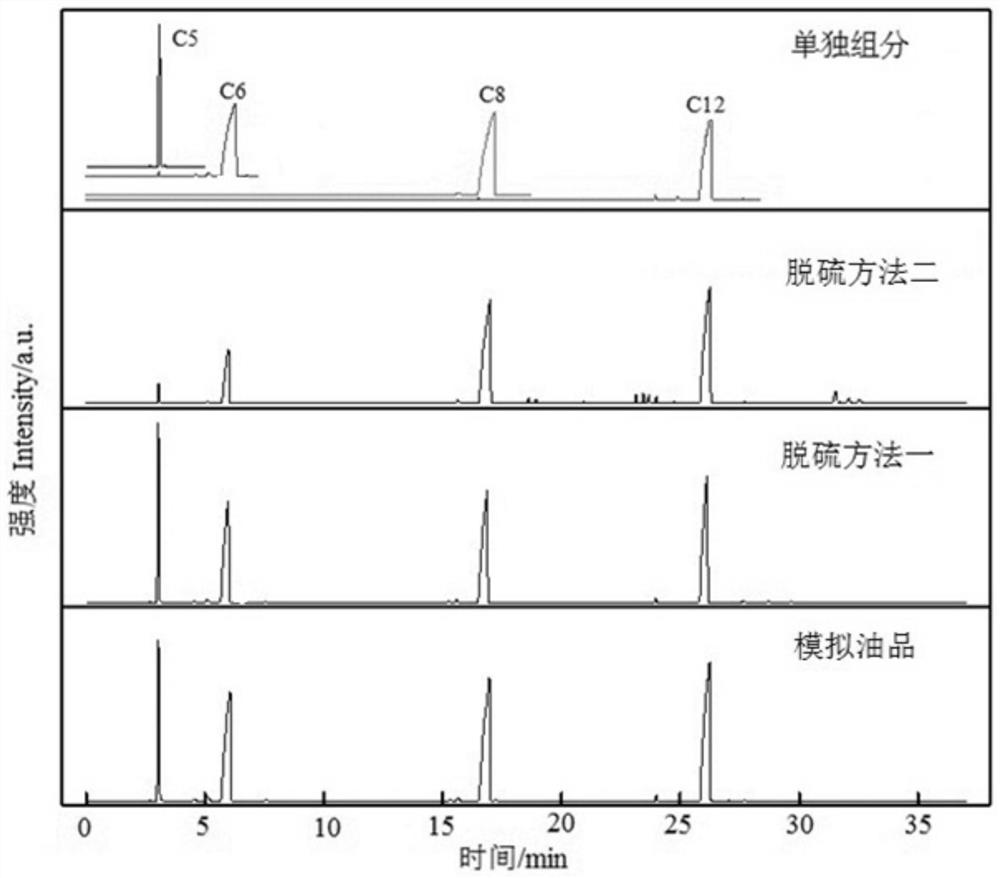

[0062] Extraction: at 20°C, mix 20mL of oil to be desulfurized (octane simulated oil with a sulfur content of 500ppm) and 40mL of deep eutectic solvent (dissolve 0.08mol tetrabutylammonium bromide in 0.12mol acetic acid , and stirred in a water bath at 90°C for 2h to obtain a light yellow transparent liquid, which was cooled to room temperature at 20°C to obtain the deep eutectic solvent) was added to Reactor 1 for mixing, and magnetically stirred at a speed of 2500rpm After 4 minutes, turn off the magnetic stirring and let it stand until the solution is separated into phases to obtain the first oil phase and the first extraction phase. Then, by adjusting the lifting of the first lifting platform 4 and the second l...

Embodiment 3

[0067] An embodiment of the present invention provides a phase-separated desulfurization method based on ozone oxidation, that is, the phase-separated desulfurization device based on ozone oxidation in Example 1 is used, and the method includes the following steps:

[0068] Extraction: at 23°C, mix 20mL of oil to be desulfurized (octane simulated oil with a sulfur content of 500ppm) and 10mL of deep eutectic solvent (dissolve 0.12mol tetrabutylammonium bromide in 0.08mol acetic acid , and stirred in a water bath at 80°C for 2h to obtain a light yellow transparent liquid, which was cooled to room temperature at 23°C to obtain the deep eutectic solvent) was added to Reactor 1 for mixing, and magnetically stirred for 7min at a speed of 1800rpm Finally, turn off the magnetic stirring and let it stand until the solution is separated into phases to obtain the first oil phase and the first extraction phase, and then adjust the lifting of the first lifting platform 4 and the second lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com