A combined solar greenhouse with separate enclosed areas

A closed area, solar greenhouse technology, applied in the field of solar greenhouse, can solve the problems of short high temperature maintenance time, impossible to reach more than 60 ℃, uneconomical from an economic point of view, etc., to achieve the effect of accelerating the heating speed and improving the heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

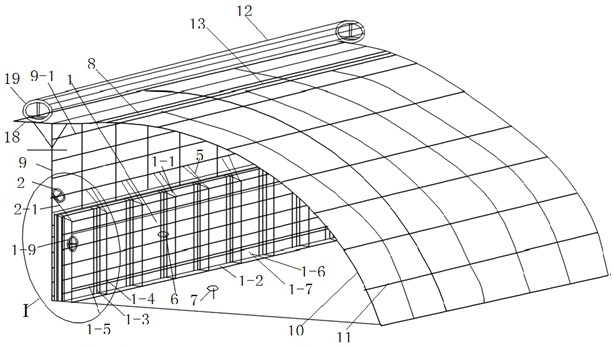

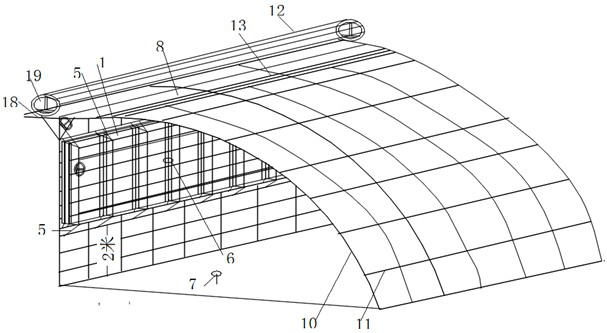

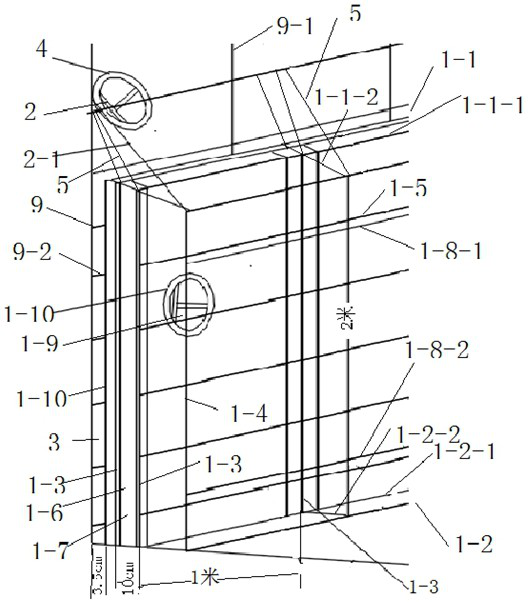

[0016] like figure 1 , figure 2 , image 3 , Figure 4 As shown in the figure, a combined solar greenhouse with an independent enclosed area includes a greenhouse roller shutter machine I19, an opening system 8, a rear wall 9, an arched beam 10, a greenhouse thermal insulation quilt I12, a greenhouse film I13, and a greenhouse lateral pulling tube I11, The rear wall 9 includes a rear wall column 9-2 and a rear wall transverse tube 9-1, and the upper ends of the arched beams 10 arranged at intervals are arranged on the upper ends of the rear wall columns 9-1 arranged at intervals on the rear wall 9 and extend 1.1 meters. The left and right are used as support rods of the rolling shutter machine, and the other end is set on the ground anchor. The side columns 14 on both sides of the greenhouse support the arched beam 10 into a smooth arch slope, and the rear wall 9 is perpendicular to the ground; in order to fix the arched beam 10, increase For the wind resistance of the gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com