Material treatment equipment for power field effect transistor processing

A power field effect tube and material processing technology, applied in the direction of inorganic chemistry, non-metallic elements, silicon compounds, etc., can solve the problems that fuel cannot be burned repeatedly, affects the processing effect of equipment, and reduces the processing temperature of equipment, so as to improve the utilization rate , increase temperature, reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

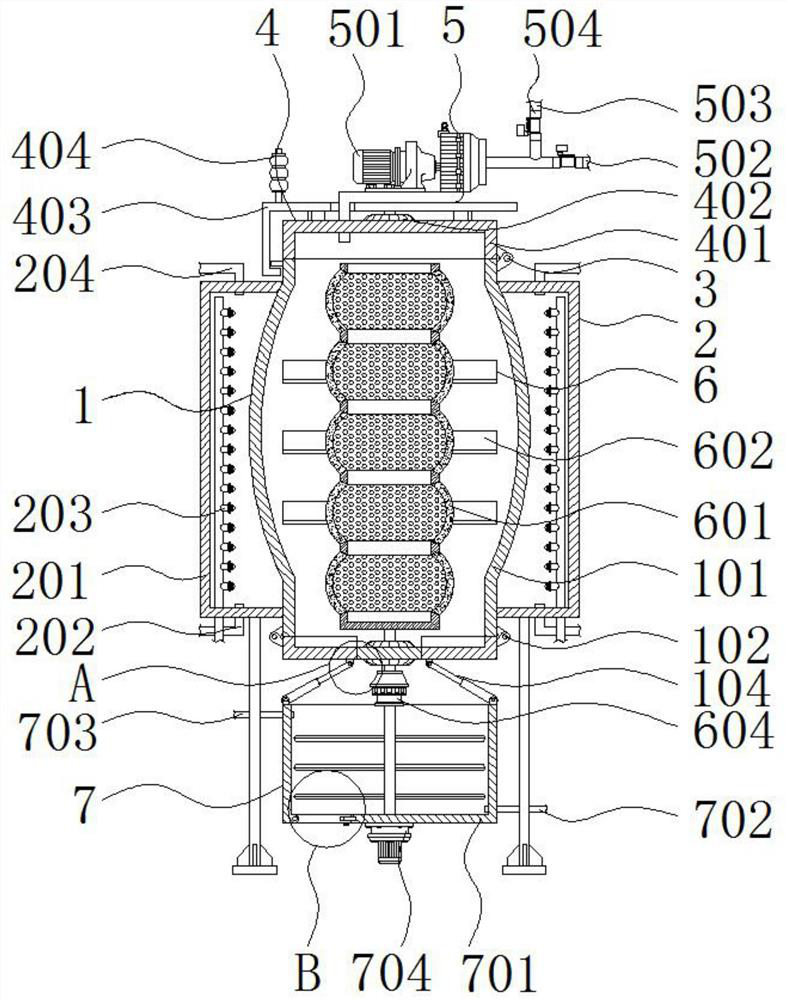

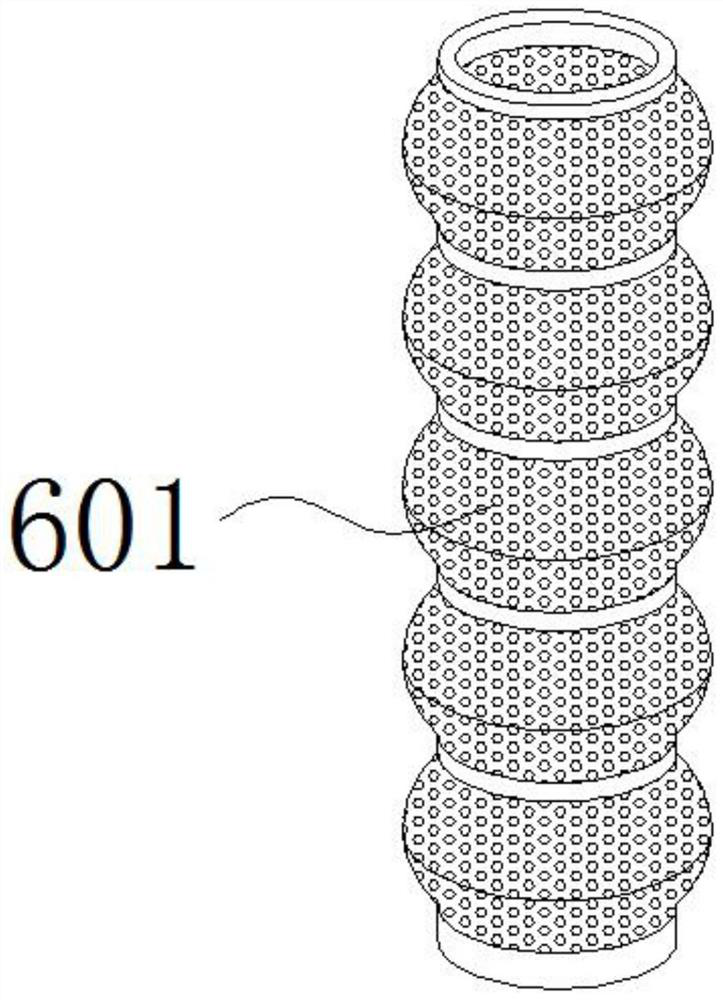

[0028] Such as Figure 1 to Figure 5 As shown, the present invention provides a technical solution: a material processing equipment for power field effect tube processing, including a box assembly 1 and a heating assembly 2, the outside of the box assembly 1 is wrapped with a heating assembly 2, and the heating assembly 2 includes a heating Casing 201, oxygen adding pipe 202, fire spray pipe 203 and exhaust pipe 204, and the lower end of heating box 201 is connected with oxygen adding pipe 202, and the inside of heating box 201 is equipped with fire spray pipe 203, and the heating box The upper end of 201 is connected with an exhaust pipe 204, and four fire pipes 203 are equidistantly installed inside the heating box 201;

[0029] The specific operation is as follows, the oxygen supply pipe 202 is evenly connected with four at the lower end of the heating box body 201, and a large amount of oxygen can be passed into the inside of the heating box body 201 through the oxygen sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com