Cement-based recycled concrete

A recycled concrete and cement-based technology, applied in the field of building materials, can solve problems such as large heat of hydration, easy expansion of gel system volume, concrete cracking, etc., and achieve the effects of increased reuse rate, good synergy, and satisfactory performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

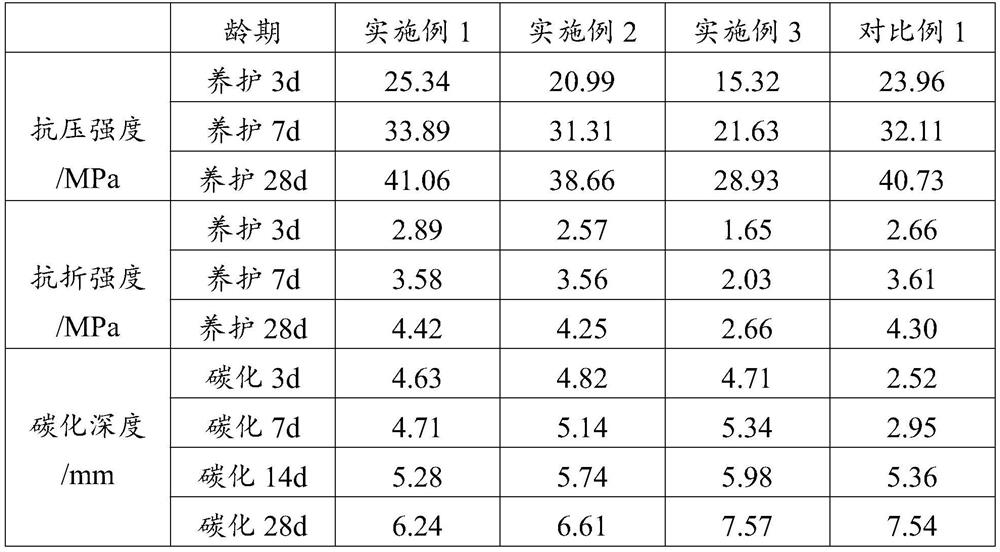

Embodiment 1

[0044] The cement-based recycled concrete prepared in this embodiment consists of the following raw materials:

[0045] P·O 42.5 Portland cement 21.6 parts, 0.1-75 μm waste granite stone powder 11.52 parts, 0.1-0.3 μm silica fume 2.88 parts, 1-5mm river sand 45.57 parts, 5-10mm gravel 60.45 parts, water 18 parts and 0.335 parts of water reducing agent;

[0046] Among them, the mass ratio of waste granite powder and silica fume is 4:1, the water reducing rate of the water reducing agent is 18%, and the composition of silica fume is SiO 2 93.24%, Al 2 o 3 3.16%, Fe 2 o 3 1.61%, CaO 1.42% and MgO 0.57%.

Embodiment 2

[0048] The cement-based recycled concrete prepared in this embodiment consists of the following raw materials:

[0049] P·O 42.5 Portland cement 21.6 parts, 0.1-75 μm waste granite stone powder 11.52 parts, 0.1-0.3 μm silica fume 2.88 parts, waste granite aggregate 79.98 parts, 1-5 mm river sand 45.57 parts, 5-10 mm 60.45 parts of gravel, 18 parts of water and 0.335 parts of water reducer;

[0050] Among them, the mass ratio of waste granite powder and silica fume is 4:1, waste granite aggregate is waste granite coarse aggregate and waste granite fine aggregate, the particle size of waste granite coarse aggregate is 5-9.5mm, waste granite fine The particle size of the aggregate is 3-4.9mm, and the mass ratio of the waste granite coarse aggregate to the waste granite fine aggregate is 3.10:1, the water reducing rate of the water reducing agent is 18%, and the composition of silica fume is SiO 2 93.24%, Al 2 o 3 3.16%, Fe 2 o 3 1.61%, CaO 1.42% and MgO 0.57%.

Embodiment 3

[0052] In Example 2, the mass ratio of the waste granite coarse aggregate to the waste granite fine aggregate is replaced by 6.19:1, and the mass fraction of crushed stone is replaced by 0, and the rest of the technical features are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com