Single-end-capped organosiloxane oligomer, silicone hydrogel, corneal contact lens and preparation methods of single-end-capped organosiloxane oligomer, and corneal contact lens

An organosiloxane, contact lens technology, applied in glasses/goggles, instruments, optics, etc., can solve problems such as affecting the wearing comfort of lenses, limiting the oxygen permeability of materials, and reducing wearing comfort, etc. Beneficial to eye health, excellent hydrophilicity, and the effect of improving oxygen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

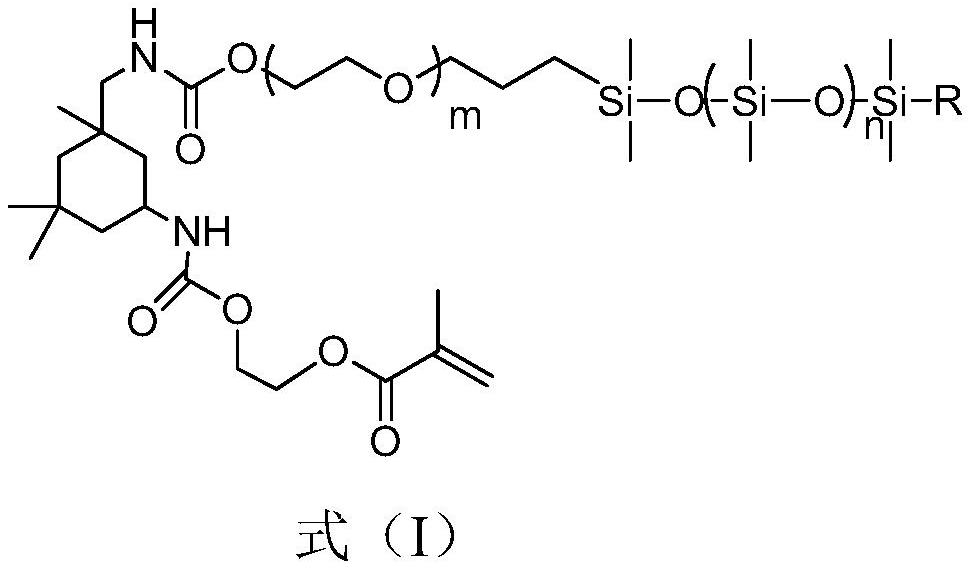

[0065] Preparation of Monoblocked Organosiloxane Oligomers

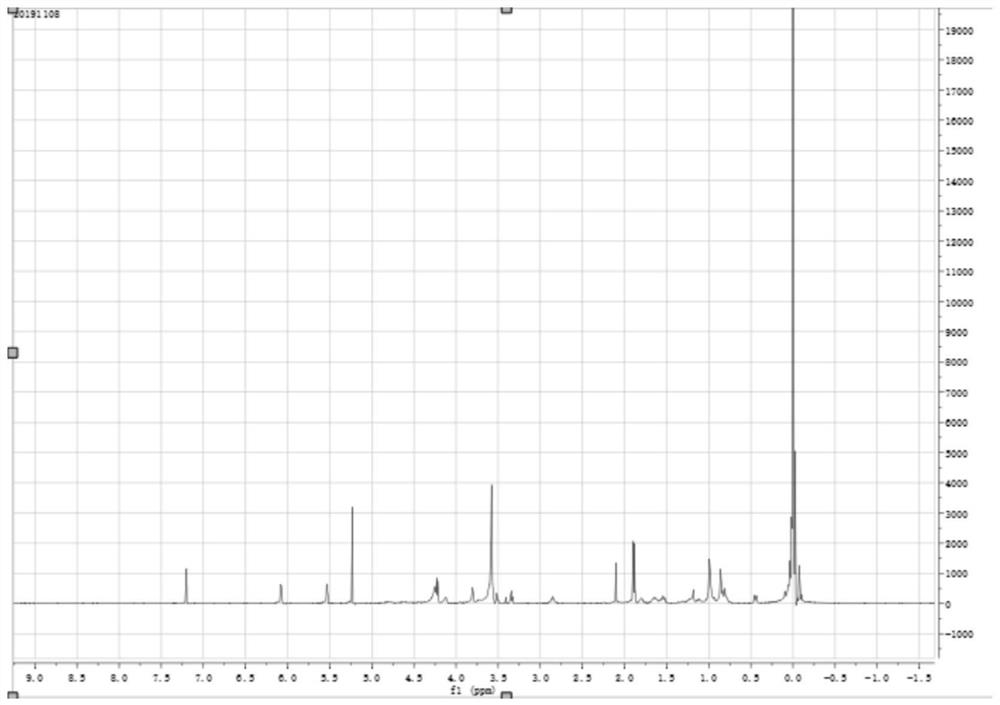

[0066] Take 50 g of polyether-modified polydimethylsiloxane (HO-PDMS) terminated by a single hydroxyl group, the number average molecular weight is about 1500, and the structural formula is as shown above, wherein m is about 8 and n is about 15, purchased from Nanjing Fu Qun Chemical Co., Ltd.), add 0.3g of dibutyltin dilaurate dropwise, stir evenly, gradually add 7.41g of IPDI, at the same time turn on the constant temperature water bath heating device, adjust the temperature to 70°C, start timing after the dropwise addition, and react for 4h. Cool down to 50°C, add 4.34 g of HEMA monomer dropwise, and stir for 24 hours to obtain the product, which is denoted as M1 (the structural formula is shown in the above formula (I), wherein m is about 8 and n is about 15), and sealed for storage. figure 1 It is the NMR spectrum of the single-terminated organosiloxane oligomer prepared in Example 1.

Embodiment 2

[0068] Preparation of Monoblocked Organosiloxane Oligomers

[0069]Take 50g of polyether-modified polydimethylsiloxane (HO-PDMS) terminated by a single hydroxyl group, the number average molecular weight is about 3000, the structural formula is as shown above, wherein m is about 10, n is about 35, purchased from Nanjing Fu Qun Chemical Co., Ltd.), add 0.2g dibutyltin dilaurate dropwise, stir evenly, gradually add IPDI 3.71g, turn on the constant temperature water bath heating device at the same time, adjust the temperature to 70°C, start timing after the dropwise addition, and react for 4h. Cool down to 50°C, add 2.17 g of HEMA monomer dropwise, and stir for 24 hours to obtain the product, which is denoted as M2 (the structural formula is shown in the above formula (I), wherein m is about 10 and n is about 35), and sealed for storage.

Embodiment 3

[0071] Preparation of Monoblocked Organosiloxane Oligomers

[0072] Take 50g of polyether-modified polydimethylsiloxane (HO-PDMS) terminated by a single hydroxyl group, the number average molecular weight is about 4000, the structural formula is as shown above, wherein m is about 12, n is about 45, purchased from Nanjing Fu Qun Chemical Co., Ltd.), add 0.2g of dibutyltin dilaurate dropwise, stir evenly, gradually add 2.78g of IPDI, and at the same time turn on the constant temperature water bath heating device, adjust the temperature to 70°C, start timing after the dropwise addition, and react for 4h. Cool down to 50°C, add 1.63 g of HEMA monomer dropwise, and stir for 24 hours to obtain the product, which is denoted as M3 (the structural formula is shown in the above formula (I), wherein m is about 12 and n is about 45), and it is sealed and stored.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com