Spinnable polycarbosilane and preparation method thereof

A technology of polycarbosilane and spinnability, applied in the field of polycarbosilane, can solve the problems of high ceramic yield, long production cycle, low viscosity, etc., and achieve the effect of improving spinnability, improving work efficiency, and good linear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

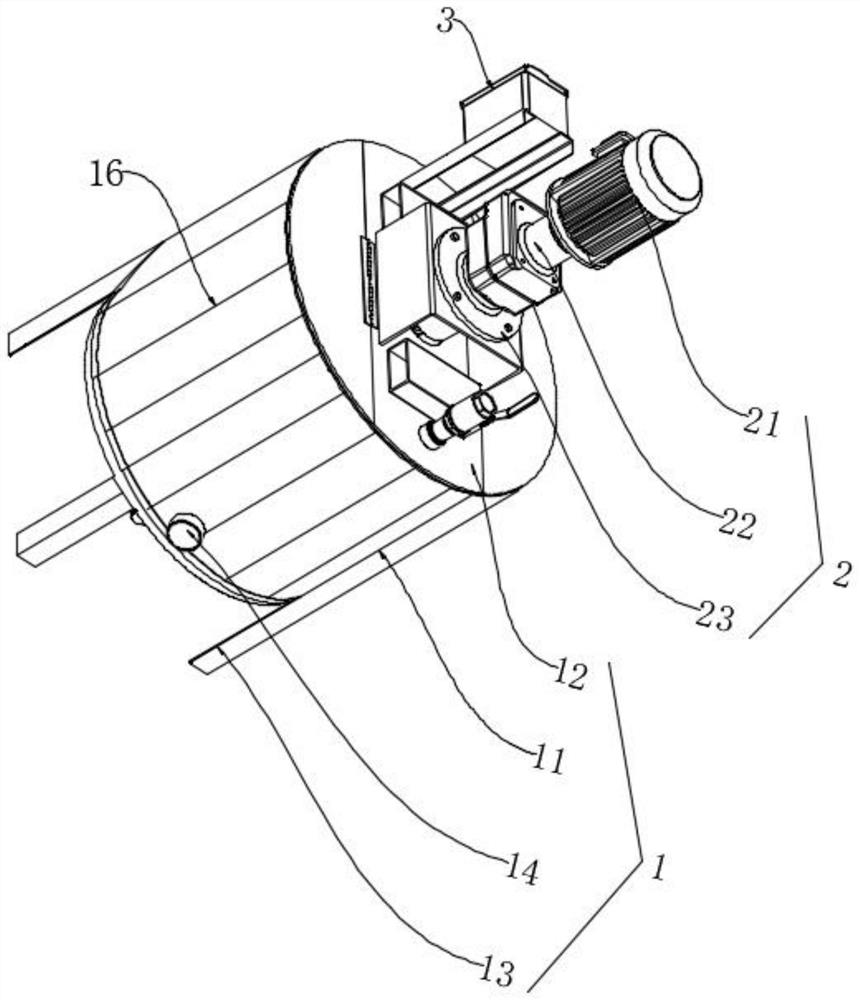

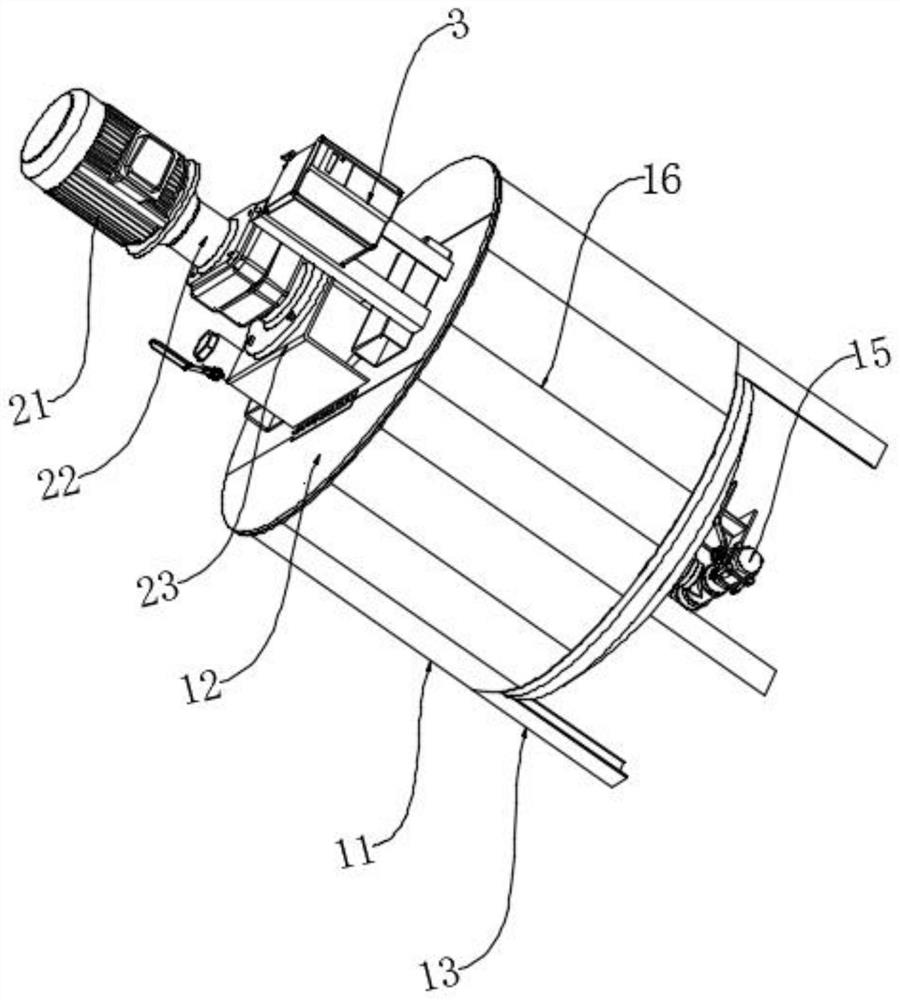

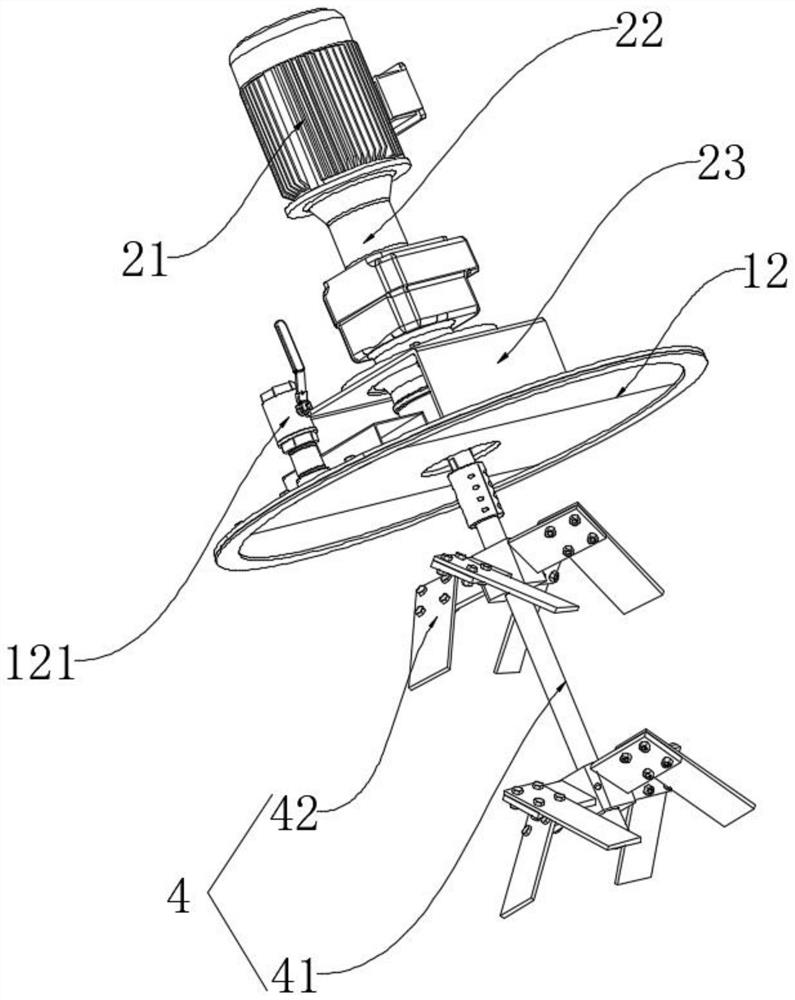

Image

Examples

Embodiment 1

[0038] In the first aspect, the embodiment of the present invention discloses a preparation method of spinnable polycarbosilane, the method comprising the following steps:

[0039] Under the protection of nitrogen, add the organic solvent and alkali metal to the mixing equipment for mixing, heat up to the melting of the alkali metal, then add dimethyldichlorosilane to the molten alkali metal for reaction, stir and mature at high temperature to obtain The reactant, by using nitrogen as protection, can make the reaction more stable, and it is not easy to chemically react with other substances, avoiding the problem of high oxygen content that does not melt in the air;

[0040] Purified water and absolute ethanol were added to the resulting mixture for multiple washings to obtain pure polydimethylsilane;

[0041] Reaction at 100-150°C for 1-6 hours to carry out polycondensation reaction to obtain polydimethylsilane to be treated;

[0042] The vacuum-dried polydimethylsilane is kept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com