Low-odor polypropylene composition as well as preparation method and application thereof

A polypropylene composition and low-odor technology, which is applied in the field of low-odor polypropylene composition and its preparation, can solve the problems of high odor and high TVOC of polypropylene composition, and achieve the effect of simple and easy preparation method and strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of above-mentioned composite adsorbent:

[0059] At 50°C, nanometer metal oxides and cationic surfactant ammonium polycarboxylate were added and mixed according to the ratio of 1:0.02%, and stirred at high speed for 3 minutes, and then the zeolite powder and activated carbon were mixed in the mixer according to the ratio in Table 1. Fully stir for 5 minutes to form the first mixture; add nano-magnesium oxide to the first mixture according to the proportions in Table 1, and fully stir for 5 minutes at 60°C to prepare composite adsorbents with different proportions, and release the use.

Embodiment 1~10 and comparative example 1~5

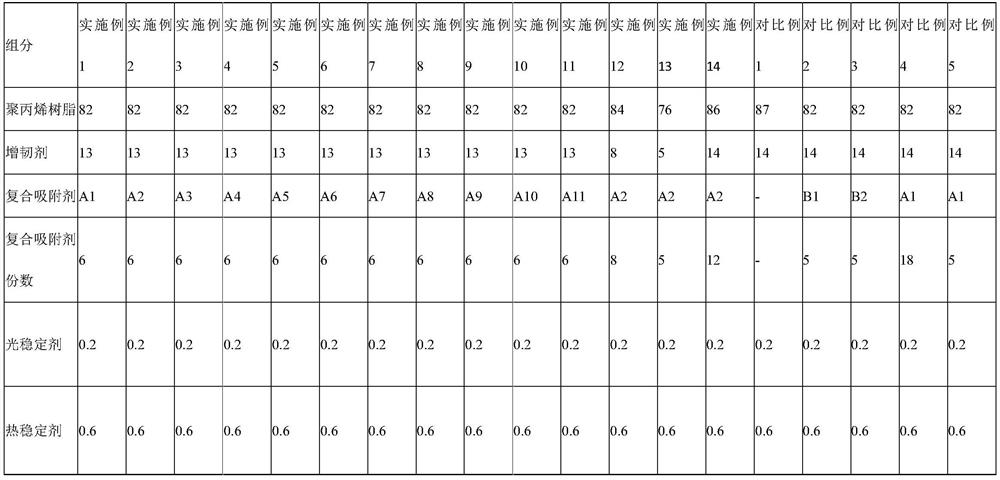

[0061] A low-odor polypropylene composition, including components calculated in parts by weight as shown in Table 2 below.

[0062] Raw material formulation and consumption (parts by weight) of the polypropylene composition of each embodiment and comparative example of table 2

[0063]

[0064] The preparation method of above-mentioned low odor polypropylene composition, comprises the steps:

[0065] Weigh polypropylene resin, toughening agent, light stabilizer, heat stabilizer by weight percentage, mix 3min in high mixer; mix evenly, obtain premix; put the premix into twin-screw extruder The composite adsorbent is added from the side feed port, the temperature is controlled at 180°C to 210°C, and the screw speed is 450 rpm, melted and extruded, granulated, dried, and cooled to obtain a polypropylene composition. Among them, the components of the composite adsorbent A1 in the preparation process of Comparative Example 6 were not prepared in advance, but zeolite powder, act...

Embodiment 1

[0080] Comparing Example 1 with Comparative Example 1, it can be seen that the addition of the composite adsorbent in Example 1 can indeed effectively reduce various small volatile molecules and organic compounds in the polypropylene composition.

[0081] Comparing Example 1 with Comparative Example 2, the composite adsorbent of Comparative Example 2 does not add nanometer metal oxides, the acid absorption effect of the system is missing, the effect of absorbing odor is not good, and the tensile strength and flexural modulus are significantly reduced.

[0082] Comparing Example 1 with Comparative Example 3, the composite adsorbent of Comparative Example 3 added nano-magnesia with a larger particle size, the adsorption of the system to gas is relatively reduced, and the tensile strength and flexural modulus are also adversely affected.

[0083] Comparing Example 1 with Comparative Example 4, the amount of composite adsorbent used in Comparative Example 4 is too much, and the ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com