Novel granulocyte separation method

A separation method, granulocyte technology, applied in the field of granulocyte separation, can solve problems such as low purity, red blood cell adhesion, and short shelf life of reagents, and achieve the effect of improving purity and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A new method for separating granulocytes, specifically comprising the following steps:

[0023] Step 1, configuring percoll with a density of 1.090g / mL;

[0024] Step 2, using commercialized ficoll with a density of 1.077g / mL to perform gradient density centrifugation on peripheral blood;

[0025] Step 3, removing the centrifuged supernatant, middle buffy coat and ficoll layer, leaving the bottom red blood cell mixture;

[0026] Step 4, wash the mixture once with PBS solution to remove the ficoll;

[0027] Step 5. Slowly add the washed cell mixture into the prepared 1.090g / mL percoll, and centrifuge at 400g for 20min;

[0028] Step 6, take out the middle layer after centrifugation;

[0029] Step 7, using the erythrocyte lysate to lyse the erythrocytes mixed in the centrifuged middle layer;

[0030] Step 8, adding PBS solution, washing away the red blood cell lysate, and the harvested cells are granulocytes.

Embodiment 2

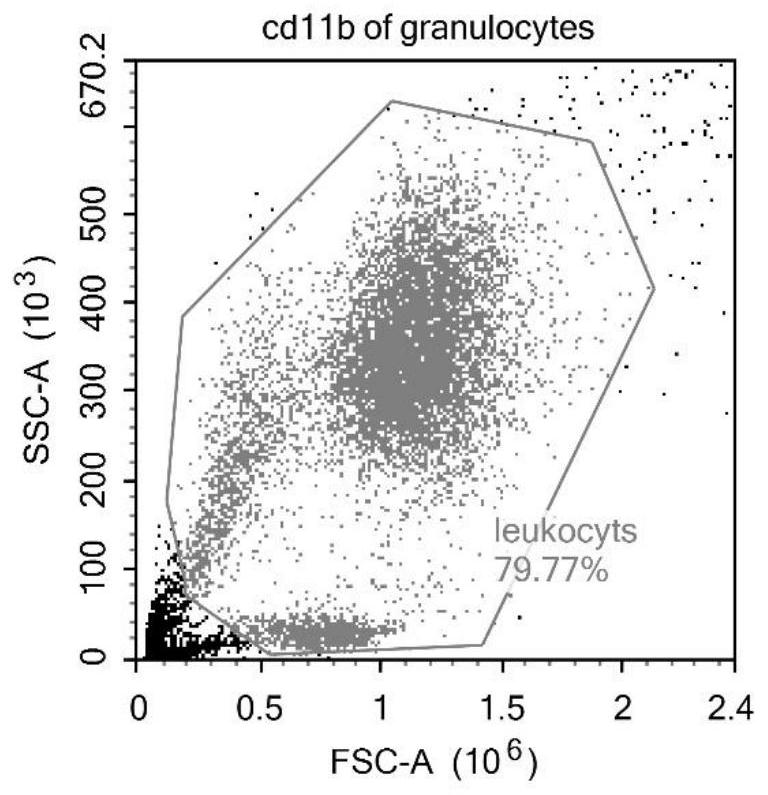

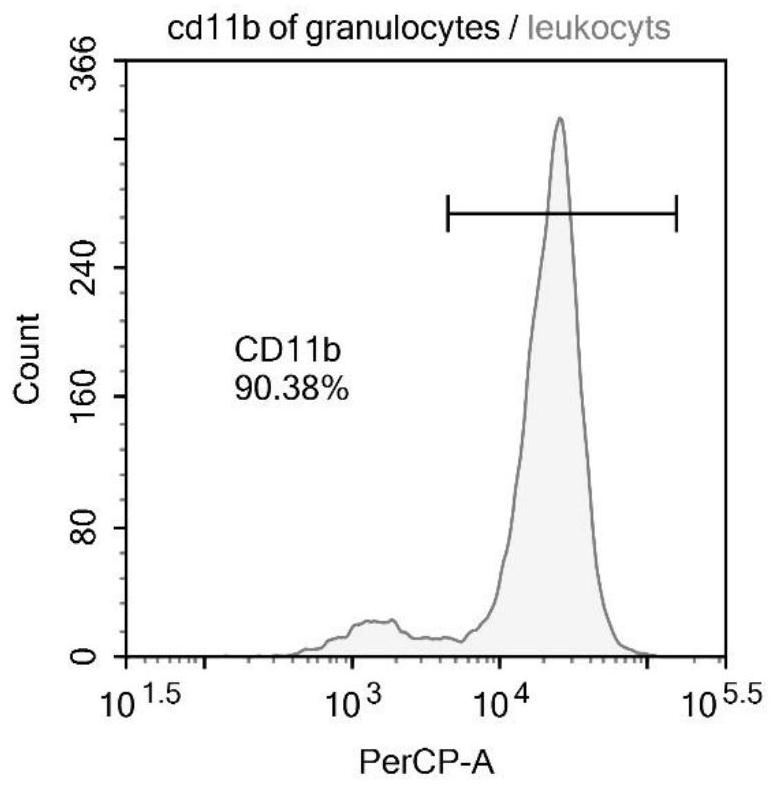

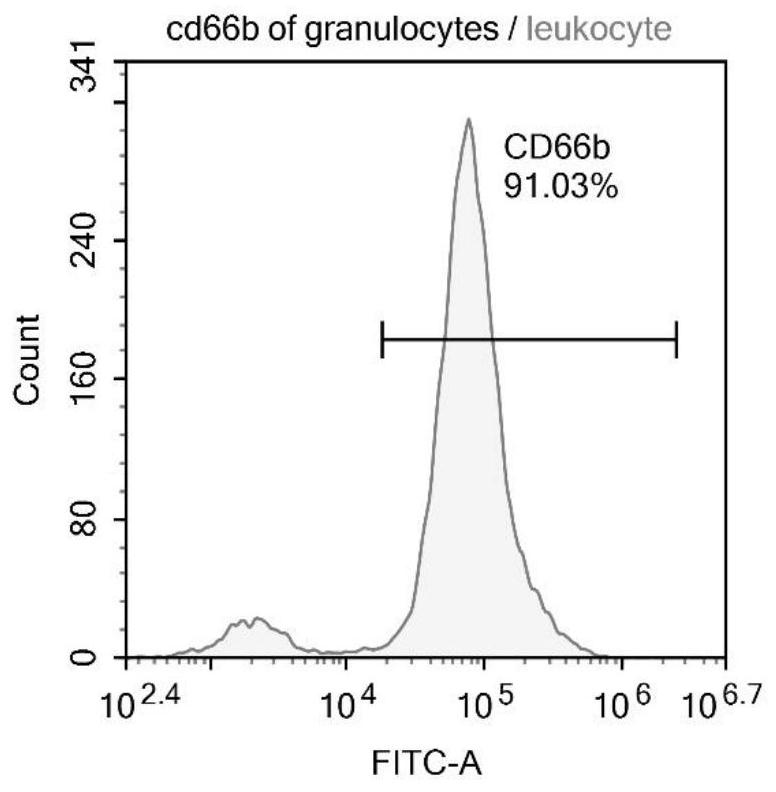

[0032] A new granulocyte separation method specifically includes the following steps, and the method is verified by a verification test, and the verification test results are as follows: Figure 1-Figure 3 Shown:

[0033] Step 1, configuring percoll with a density of 1.090g / mL;

[0034] Step 2, using commercialized ficoll with a density of 1.077g / mL to perform gradient density centrifugation on peripheral blood;

[0035] Step 3, removing the centrifuged supernatant, middle buffy coat and ficoll layer, leaving the bottom red blood cell mixture;

[0036] Step 4, wash the mixture once with PBS solution to remove the ficoll;

[0037] Step 5. Slowly add the washed cell mixture into the prepared 1.090g / mL percoll, and centrifuge at 400g for 20min;

[0038] Step 6, take out the middle layer after centrifugation;

[0039] Step 7, using the erythrocyte lysate to lyse the erythrocytes mixed in the centrifuged middle layer;

[0040] Step 8, adding PBS solution, washing away the red ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com