Production process and equipment for whitened low-shrinkage and medium-fine-denier polyamide yarns

A fine-denier nylon yarn and production process technology, applied in the field of textile yarn, can solve the problems of large heat shrinkage, shrinkage deformation, whiteness reduction, etc., achieve performance optimization, improve heat shrinkage rate, and avoid high-temperature oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

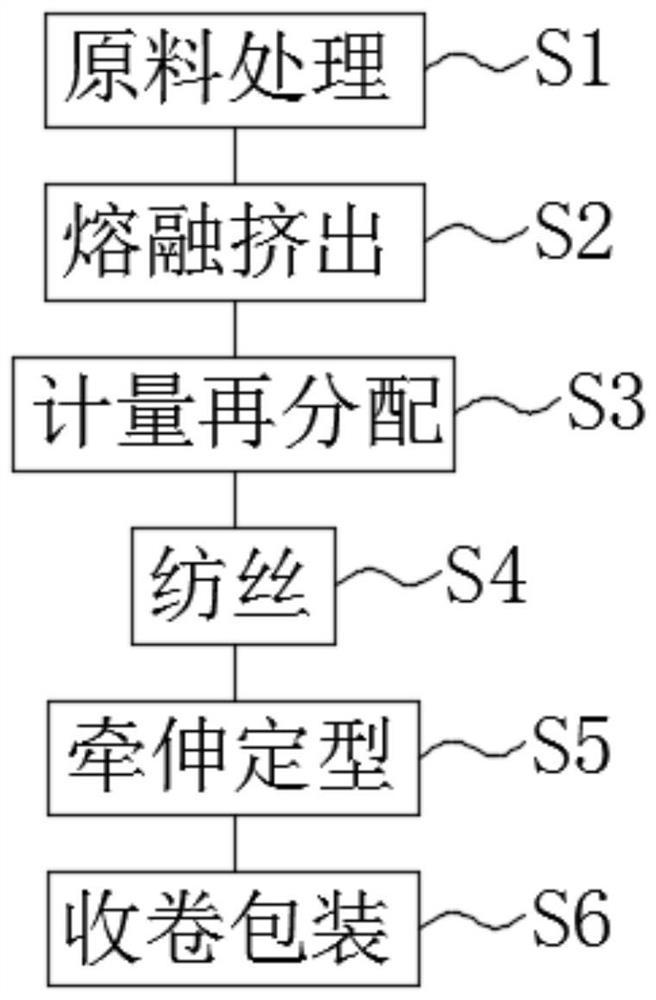

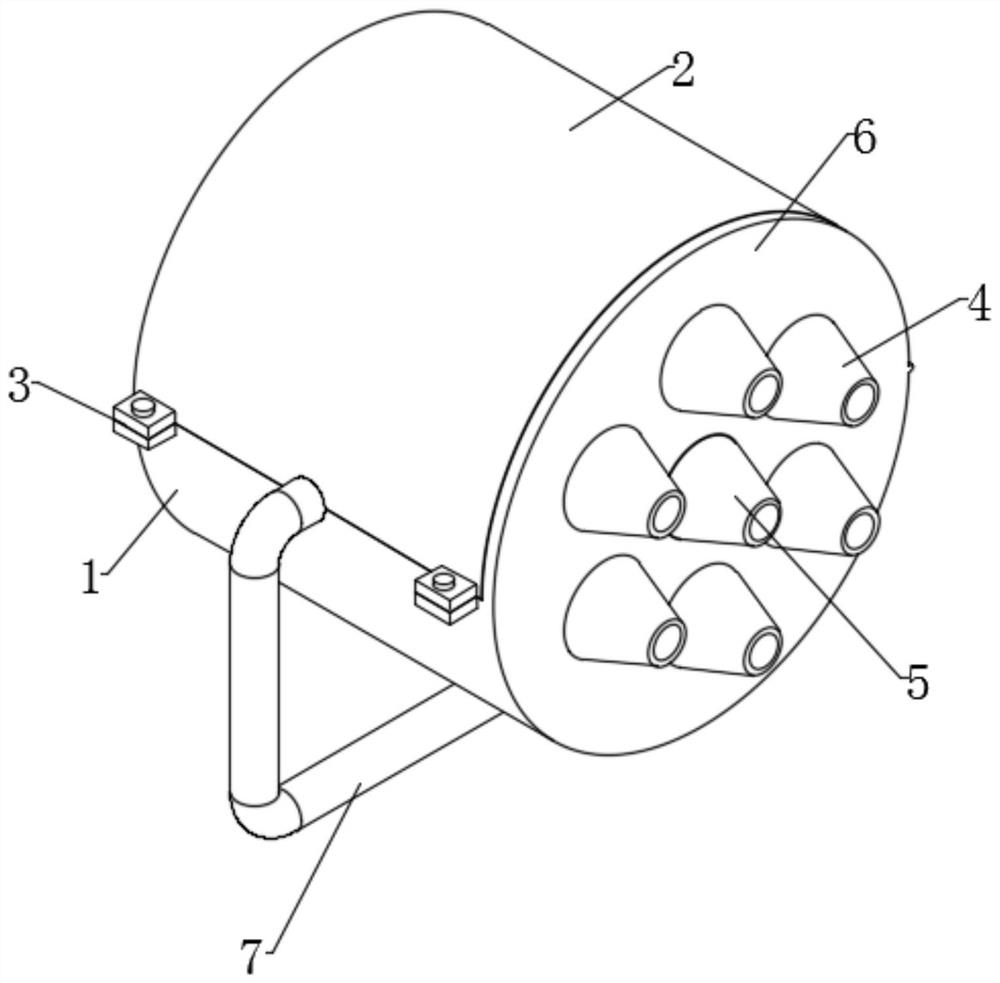

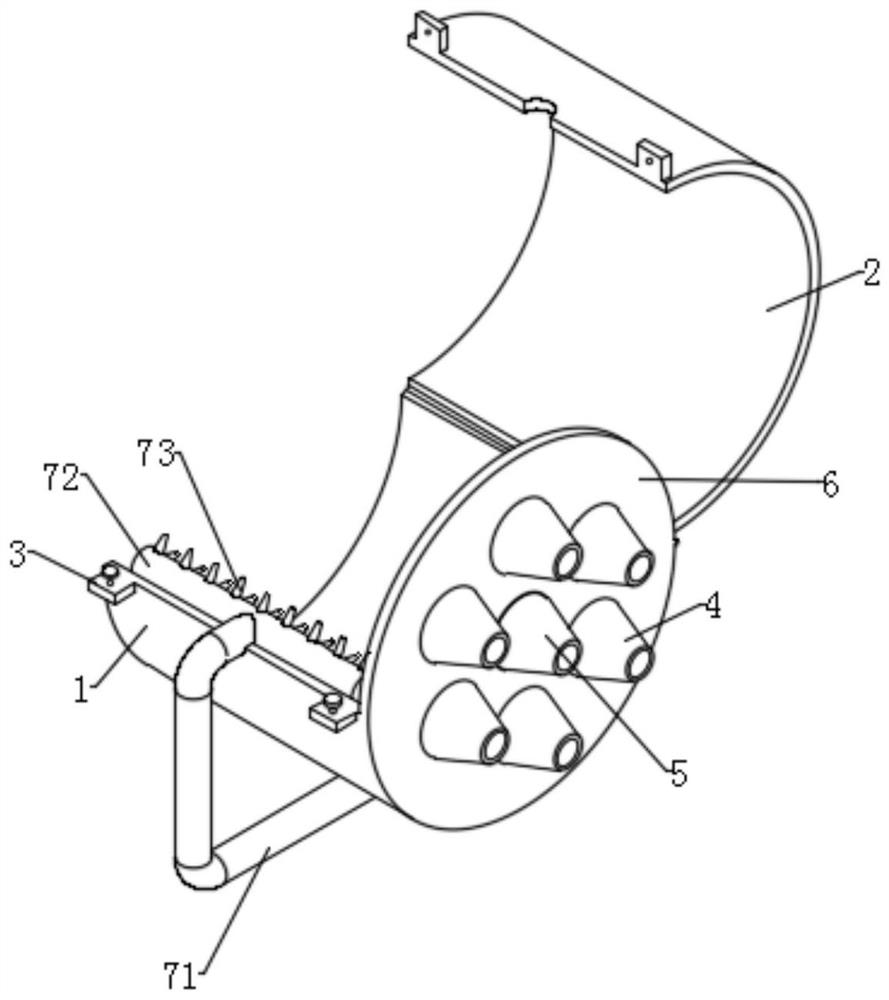

[0038] see Figure 1-4 , the present invention provides a technical solution: the production process of whitening low-shrinkage medium-fine nylon yarn, comprising the following steps:

[0039] S1. Raw material processing

[0040] Prepare the auxiliary agent, weigh the auxiliary agent and nylon 66 according to the proportion, slice the nylon 66 raw material, put it into the drying tower via a crane, and dry it continuously under the protection of nitrogen for later use;

[0041] S2, melt extrusion

[0042] After the dried nylon 66 and auxiliary agents are mixed according to the ratio through a high-speed mixer, they are added to a screw extruder for melting, and then evenly distributed to each melt pipe under pressure, and filtered to filter out impurities;

[0043] S3. Measured redistribution

[0044] The filtered melt passes through a static mixer and is further mixed in the static mixer. The static mixer is connected to a metering pump through a pipeline, and the metering...

Embodiment 2

[0061] see Figure 1-4 , the present invention provides a technical solution: the production process of whitening low-shrinkage medium and fine denier nylon yarn, comprising the following steps:

[0062] S1. Raw material processing

[0063] Prepare the auxiliary agent, weigh the auxiliary agent and nylon 66 according to the proportion, slice the nylon 66 raw material, put it into the drying tower via a crane, and dry it continuously under the protection of nitrogen for later use;

[0064] S2, melt extrusion

[0065] After the dried nylon 66 and auxiliary agents are mixed according to the ratio through a high-speed mixer, they are added to a screw extruder for melting, and then evenly distributed to each melt pipe under pressure, and filtered to filter out impurities;

[0066] S3. Measured redistribution

[0067] The filtered melt passes through the static mixer and is further mixed in the static mixer. The static mixer is connected to the metering pump through the pipeline,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com