Frozen pre-fried fish steak and processing method thereof

A processing method and technology for fish steak, which are applied in the field of frozen pre-fried fish steak and processing, can solve the problems of nutritional quality, flavor damage, weak overall taste, lack of umami, etc., so as to ensure health, improve product flavor, and improve freshness. taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

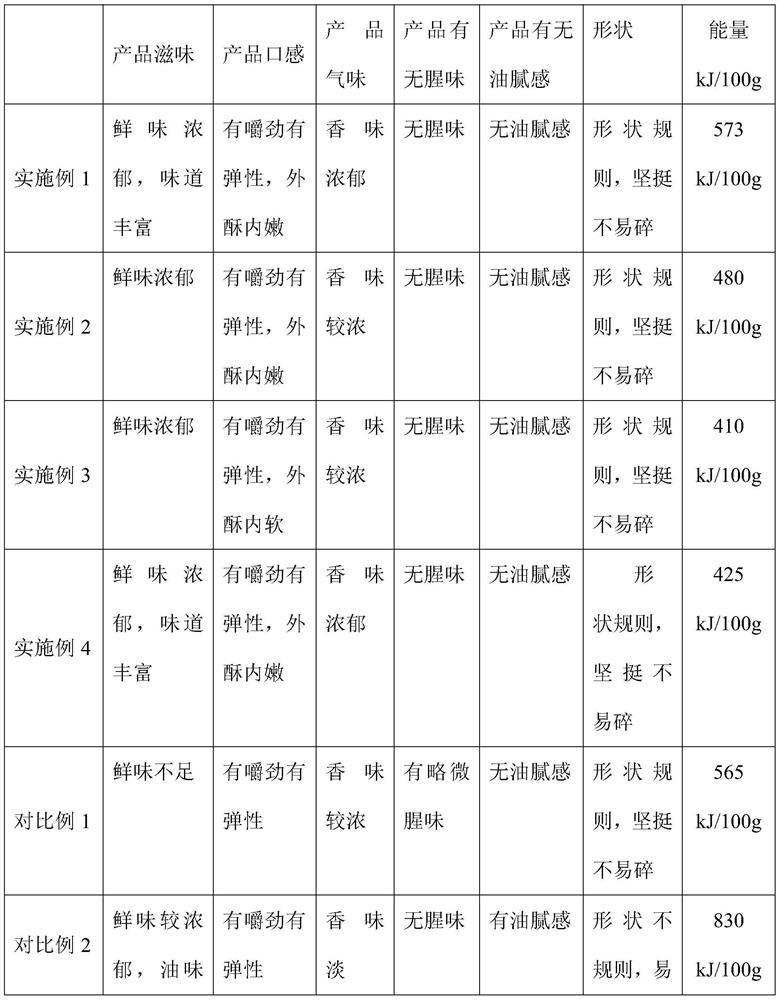

Examples

Embodiment 1

[0038] 1. Thaw the frozen fish in running water until the carcass becomes soft, cut off the fish meat along the fish bone and slice it into uniform thin slices;

[0039] 2. Coat the fish fillets with batter powder. In parts by weight, the raw materials of the frozen pre-fried fish fillets in this embodiment include 30 parts of fish meat, 10 parts of batter powder, 5 parts of bread crumbs and 15 parts of water; the batter powder is based on wheat flour, cornstarch and hydrolyzed oyster Flour is an auxiliary material for battering, and the weight ratio of wheat flour, corn starch, and hydrolyzed oyster powder is 100:30:10. Before the battering operation, the batter needs to be prepared in advance. In this embodiment, battering powder and water are used to prepare the batter, and the battering powder and 200 parts by weight of water are mixed to form a slurry, so as to sizing the battered fish fillet. The fish fillets after sizing are breaded, and the raw materials used for the ...

Embodiment 2

[0047] 1. Thaw the frozen fish in running water until the carcass becomes soft, cut off the fish meat along the fish bone and slice it into uniform thin slices;

[0048] 2. Coat the fish fillets with batter powder. In parts by weight, the raw materials of the frozen pre-fried fish fillets in this embodiment include 25 parts of fish meat, 8 parts of batter powder, 4 parts of bread crumbs and 15 parts of water; the batter powder is based on wheat flour, cornstarch and hydrolyzed oyster Flour is an auxiliary material for battering, and the weight ratio of wheat flour, corn starch, and hydrolyzed oyster powder is 100:35:7. Before the battering operation, it is necessary to mix the batter in advance. In this embodiment, battering powder and water are used to prepare the batter, and the battering powder and 200 parts by weight of water are mixed to form a slurry, so that the battered fish fillets are battered. The fish fillets after sizing are wrapped in bread crumbs, and the raw ...

Embodiment 3

[0053] 1. Thaw the frozen fish in running water until the carcass becomes soft, cut off the fish meat along the fish bone and slice it into uniform thin slices;

[0054] 2. Coat the fish fillets with batter powder. In parts by weight, the raw materials of the frozen pre-fried fish fillet in this embodiment include 20 parts of fish meat, 5 parts of batter powder, 3 parts of bread crumbs and 7 parts of water; the batter powder is based on wheat flour, cornstarch and hydrolyzed oyster Flour is an auxiliary material for coating, and the weight ratio of wheat flour, corn starch and hydrolyzed oyster powder is 100:40:5. Before the battering operation, it is necessary to mix the batter in advance. In this embodiment, battering powder and water are used to prepare the batter, and the battering powder and 200 parts by weight of water are mixed to form a slurry, so that the battered fish fillets are battered. The fish fillets after sizing are breaded, and the raw materials used for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com