A method for preparing a full-section fine-grained gh4169 alloy diameter forged rod

A GH4169, full-section technology, which is used in the preparation of full-section fine-grained GH4169 alloy radial forging bars, can solve the problems of difficult to obtain fine grains and poor organizational uniformity, and achieve the effect of not easily falling off and ensuring consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the full-section fine-grained GH4169 alloy radially forged bar of the present invention specifically comprises the following steps:

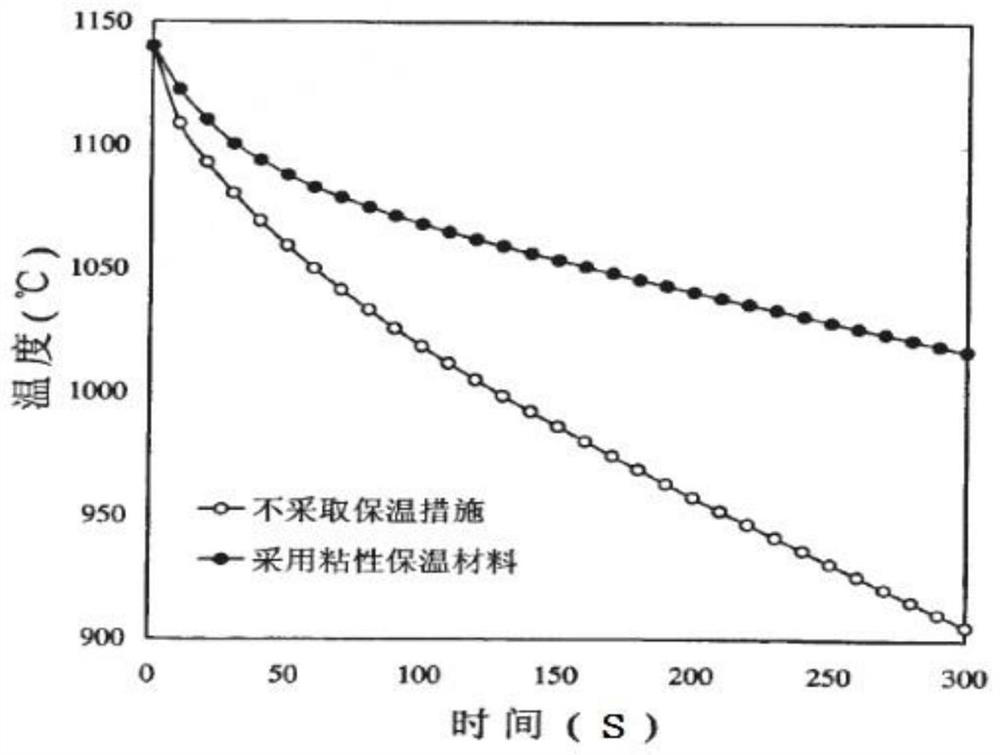

[0041] Step 1, the GH4169 ingot after high temperature homogenization is forged and opened for 2-3 times, and the heating temperature is controlled to 1050-1130°C (such as 1060°C, 1070°C, 1080°C, 1090°C, 1100°C, 1110°C, 1120°C), in the process of forging and blanking, a step-by-step cooling mode is adopted between different fires. , the third fire is 1060 ± 10 ℃; the forging ratio is controlled to be ≥ 4 to prepare the diameter forging billet, and the ingot is prepared into a diameter forging billet after forging.

[0042] The high temperature homogenization treatment of GH4169 ingot adopts two-stage method, the first stage is kept at 1160±10℃, and the heat preservation time is not less than 32h, and the second stage is kept at 1195±10℃, and the heat preservation time is not less than 72h. Among them, the forgin...

Embodiment 1

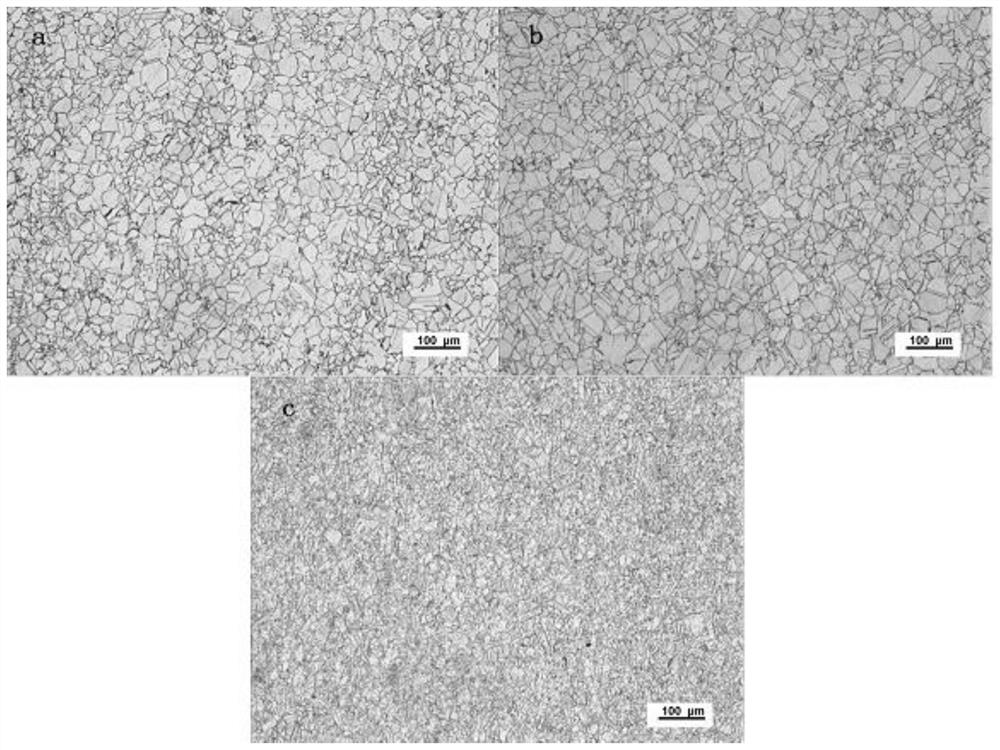

[0055] This embodiment provides a method for preparing a full-section fine-grained GH4169 alloy radial forging bar, which is prepared as The GH4169 alloy bar includes the following steps:

[0056] Step 1. After high temperature homogenization The consumable ingots are forged and opened for the first fire on a 45MN or 60MN rapid forging hydraulic press, the heating temperature is controlled at 1120±10℃, the reduction amount of each hammer is controlled at 60-100mm, and the deformation amount of the first fire is ≥45% , the final forging temperature is ≥880°C, and the billet is made to 360-380mm hexagonal (that is, the cross-section of the billet is hexagonal, and the maximum length of the section is 360-380mm, the concept of the following hexagonal is similar) ;

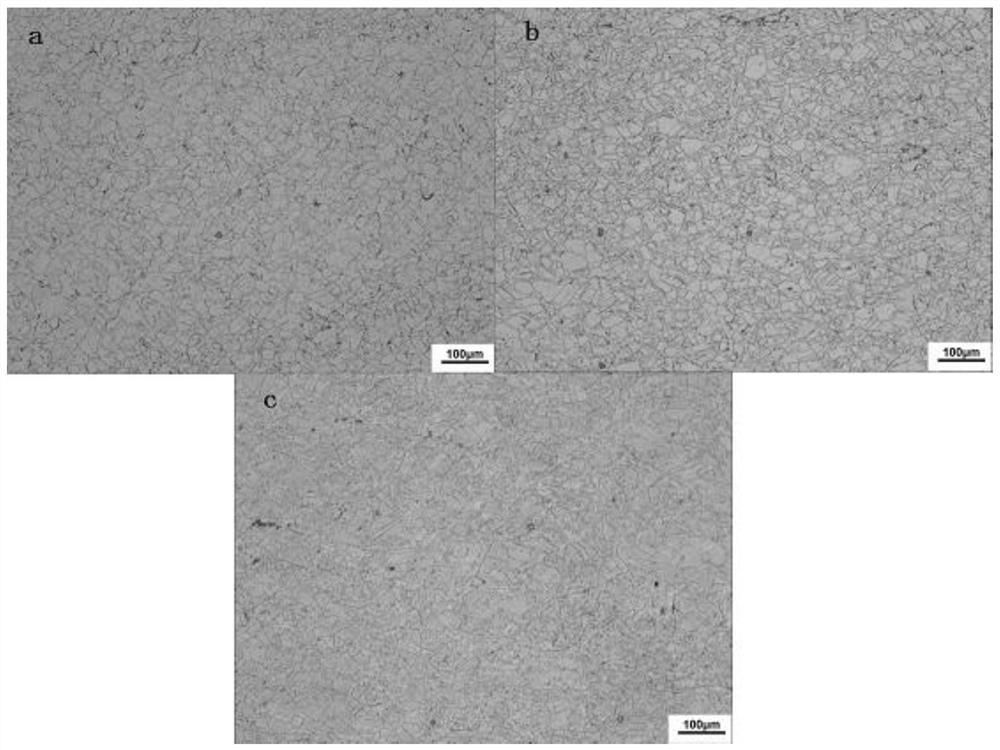

[0057] Step 2. Perform the second forging on the billet in Step 1, and use a 45MN or 60MN rapid forging hydraulic press to elongate the billet axially. The billet is made to 260-280mm hexadecimal, and all are ret...

Embodiment 2

[0062] This embodiment provides a method for preparing a full-section fine-grained GH4169 alloy radial forging bar, which is prepared as The GH4169 alloy bar includes the following steps:

[0063] Step 1. After high temperature homogenization The consumable ingots are subjected to the first fire of one upsetting and one drawing forging on a 45MN or 60MN rapid forging hydraulic press. The final forging temperature is ≥880℃, and the billet is made to 450-480mm hexadecimal;

[0064] Step 2. Perform the second forging on the billet in Step 1, and use a 45MN or 60MN rapid forging hydraulic press to elongate the billet axially. The billet is made to 350-360mm hexagonal, the deformation is ≥40%, and the final forging temperature is ≥880℃;

[0065] Step 3. Finish the surface of the billet prepared in step 2, then put it into the furnace, control the heating temperature at 990-1020 ° C, and then keep it for 3.5 hours. Fire diameter forging into a product, the final fire deformati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com