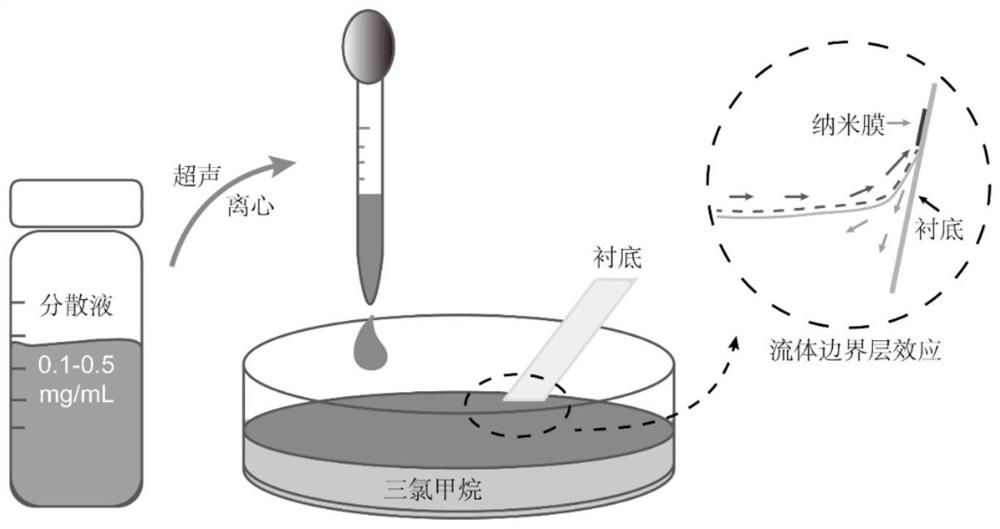

Method for self-assembling homogeneous/heterojunction nano-film by utilizing fluid boundary layer effect

A fluid boundary and self-assembly technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of low heterojunction formation efficiency, high accident risk, and high cost, and achieve assembly The effect of low environmental requirements, excellent controllability, and low experimental risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

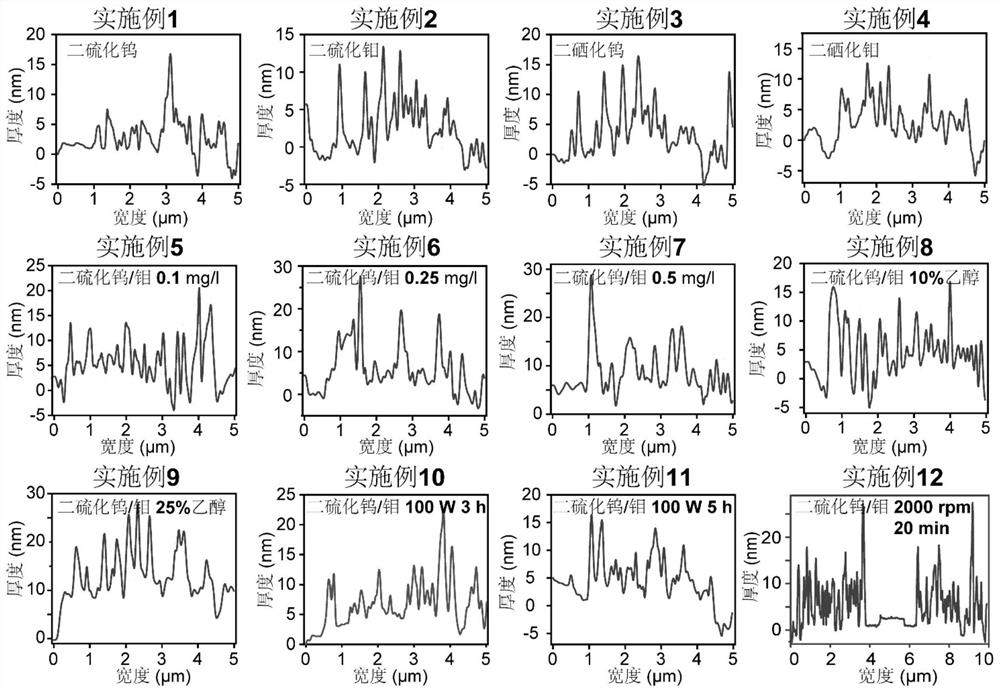

Embodiment 1

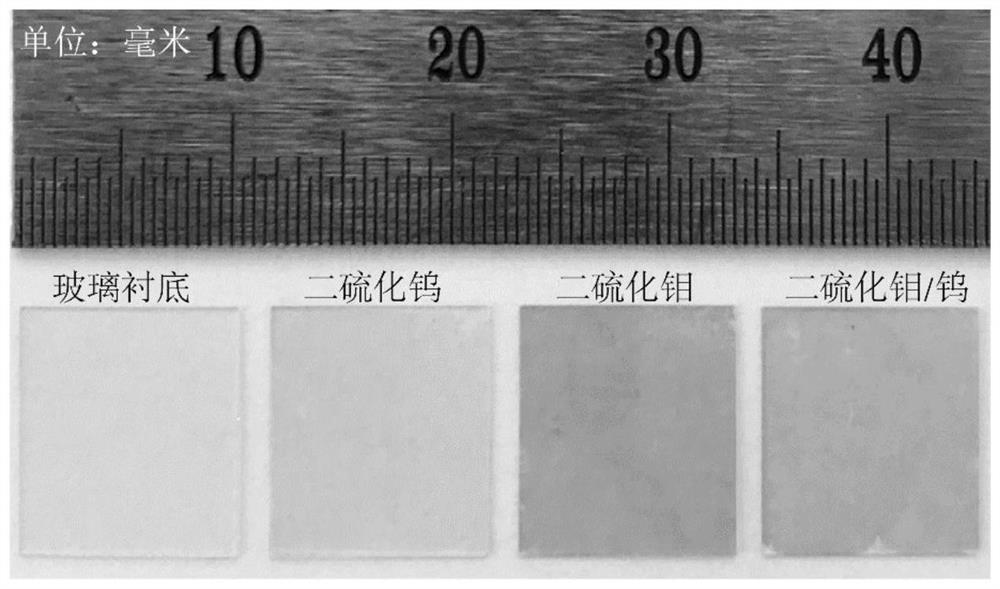

[0031] The nano-film preparation method is as follows: take 2.5 mg of tungsten disulfide nano-sheets, add 10 ml of 50% ethanol aqueous solution, shake well, and use an ultrasonic breaker to perform ultrasonication for 4 hours, so that the nano-sheets are fully broken into small fragments and uniformly dispersed; Centrifuge at 2000rpm / min for 10 minutes to separate nanosheets with large diameters, and take the upper layer to obtain a dispersion with uniform nanoparticle size. Take 5mL of the dispersion and add it to a glass dish filled with 25mL of chloroform, and the dispersion is suspended on the surface of chloroform; slowly add 50% absolute ethanol solution to make the surface of the dispersion continue to expand, and drive the nanomaterials in the two-phase solvent A thin film is formed at the interface; then the glass slide wetted with water after pickling is inserted into the solution and lifted slowly, so that the film gathers to the upper end of the slide under the effe...

Embodiment 2

[0033] The nanosheets were replaced with molybdenum disulfide nanosheets, the key parameters are shown in Table 1, and other parameters are the same as in Example 1.

Embodiment 3

[0035] The nanosheets were replaced with tungsten diselenide nanosheets, the key parameters are shown in Table 1, and other parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com