Hydrophobic antifriction self-lubricating carbon film based on low-temperature glow plasma and preparation method of hydrophobic antifriction self-lubricating carbon film

A plasma and self-lubricating technology, applied in solid diffusion coating, coating, gaseous chemical plating, etc., to achieve the effect of low preparation cost, uniform thickness and good bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Grind the M50NiL nitrided steel sample material with sandpaper, and further polish it to a low roughness state (mirror surface state is the best), and clean it in acetone or alcohol solution;

[0028] Step 2: Put the material obtained in step 1 in a plasma nitriding furnace, vacuumize to 50Pa, turn on the voltage, keep the voltage at 700V, and the duty cycle is 35%;

[0029] Step 3: Introduce propane and hydrogen at a ratio of 2:1, adjust the temperature in the furnace to 170°C and the air pressure to 55Pa, and start to prepare a hydrophobic, friction-reducing and self-lubricating carbon film;

[0030] Step 4: Keep the temperature at 170°C and the air pressure at 55 Pa for 5 hours, then cool the sample to room temperature with the furnace, and take out the sample.

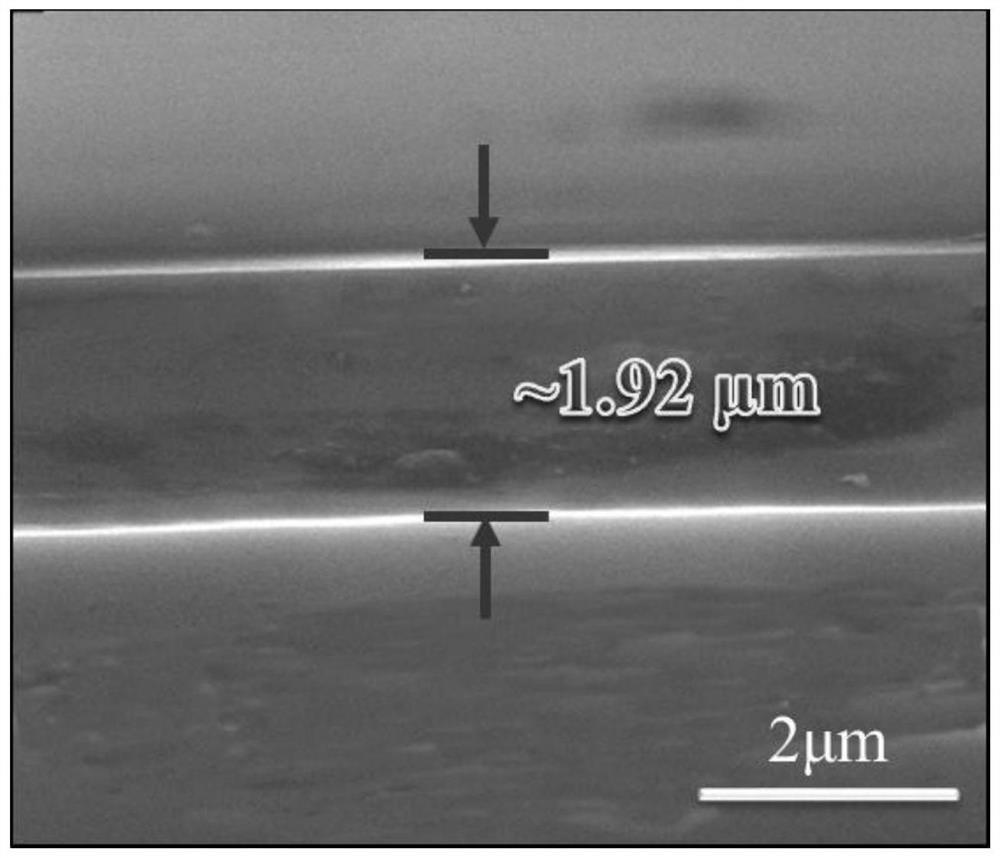

[0031] The cross-sectional morphology of the obtained carbon film is as follows figure 1 As shown, it can be seen that the carbon film has a uniform thickness and is well combined with the substrate...

Embodiment 2

[0033] Step 1: Grind the M50NiL nitrided steel sample material with sandpaper, and further polish it to a low roughness state (mirror surface state is the best), and clean it in acetone or alcohol solution;

[0034] Step 2: Put the material obtained in step 1 in a plasma nitriding furnace, vacuumize to 50Pa, turn on the voltage, keep the voltage at 700V, and the duty cycle is 35%;

[0035] Step 3: Introduce propane and hydrogen at a ratio of 2:3, adjust the temperature in the furnace to 170°C and the air pressure to 55Pa, and start to prepare a hydrophobic, friction-reducing and self-lubricating carbon film;

[0036] Step 4: Keep the temperature at 170°C and the air pressure at 55 Pa for 5 hours, then cool the sample to room temperature with the furnace, and take out the sample.

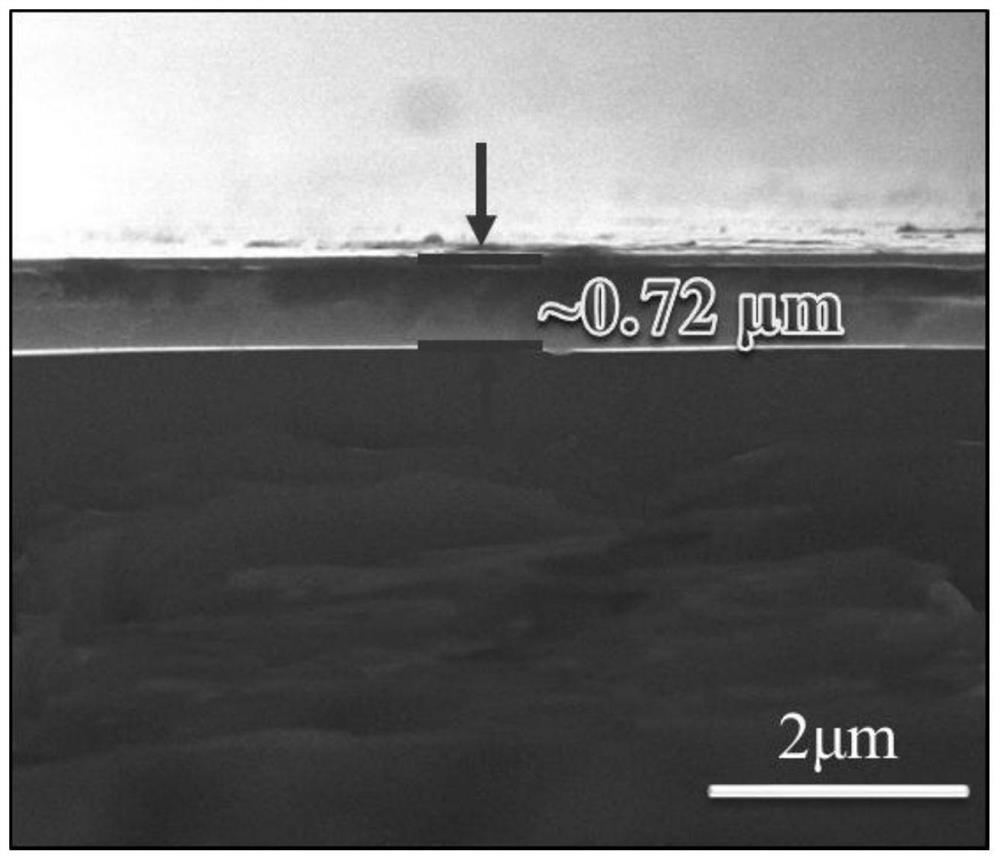

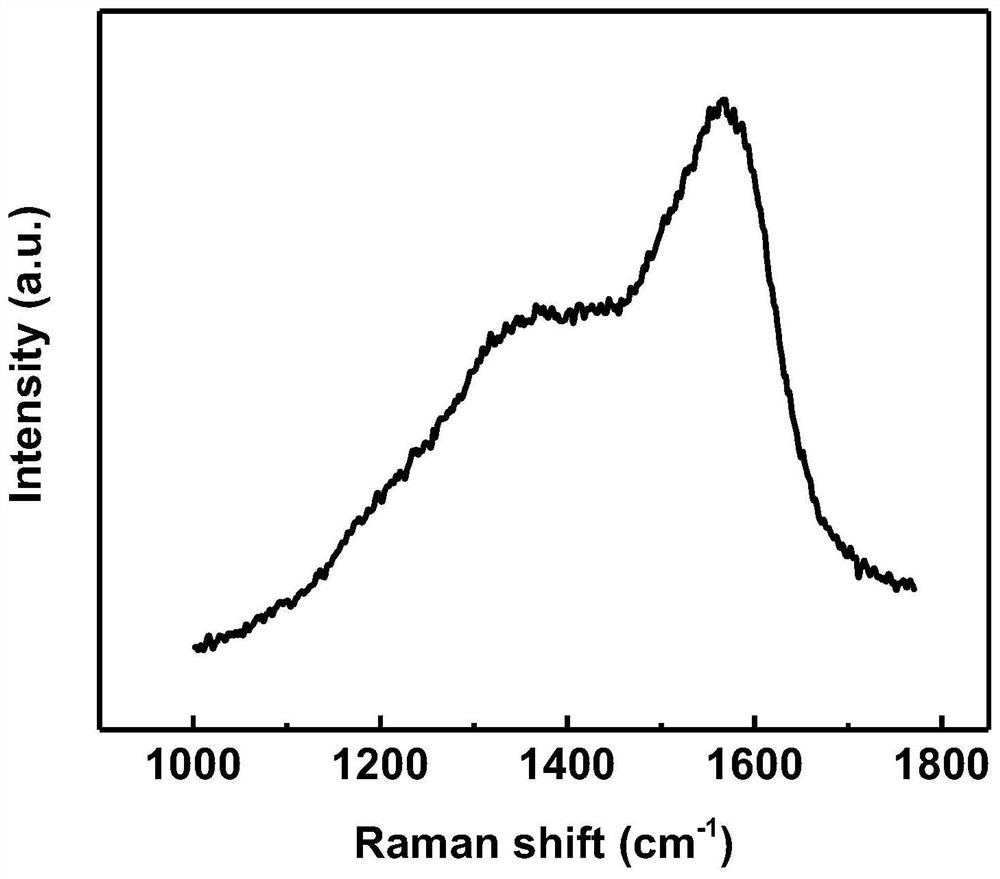

[0037] The cross-sectional morphology of the obtained carbon film is as follows figure 2 As shown, it can be seen that the thickness of the carbon film is uniform, and the XPS test results of the c...

Embodiment 3

[0039] Step 1: Grind the 4140 steel sample material with sandpaper, and further polish to a low-roughness state (mirror state is the best), and clean it in acetone or alcohol solution;

[0040] Step 2: Put the material obtained in step 1 in a plasma nitriding furnace, evacuate to 50Pa, turn on the voltage, keep the voltage at 700V, and the duty cycle is 20%;

[0041] Step 3: Introduce propane and hydrogen at a ratio of 2:3, adjust the temperature in the furnace to 170°C and the air pressure to 55Pa, and start to prepare a hydrophobic, friction-reducing and self-lubricating carbon film;

[0042] Step 4: Keep the temperature at 170°C and the air pressure at 55 Pa for 5 hours, then cool the sample to room temperature with the furnace, and take out the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com