Novel high-antibacterial and anti-ultraviolet polyester-viscose yarn

A technology of anti-ultraviolet and polyester viscose yarn, which is applied in the field of polyester viscose yarn, can solve the problems of poor antibacterial and anti-ultraviolet performance of polyester viscose yarn, and achieve the effect of improving adhesion stability, not easy to be damaged, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

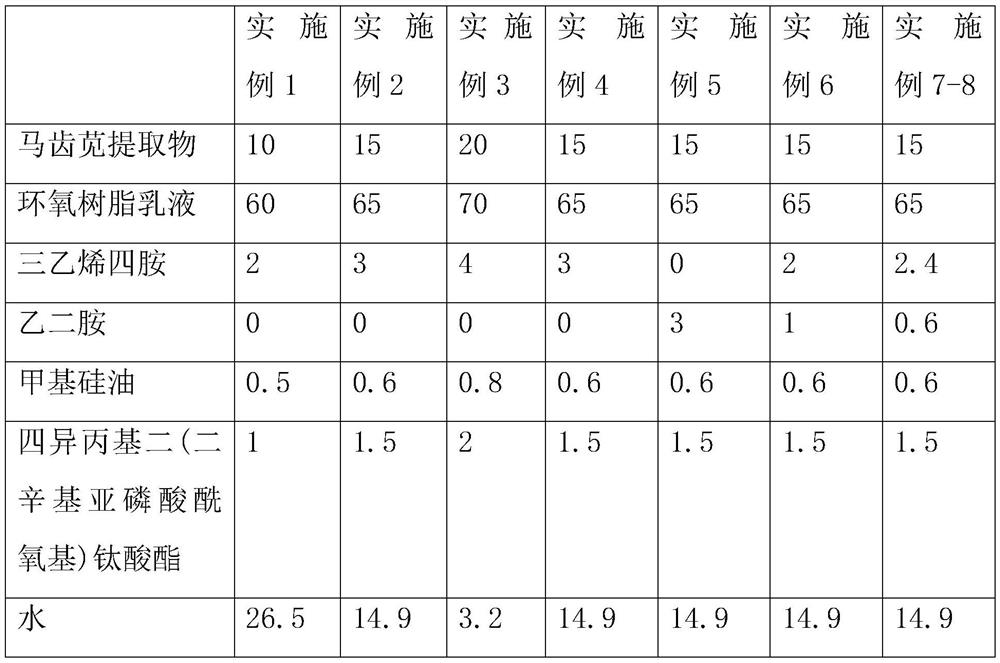

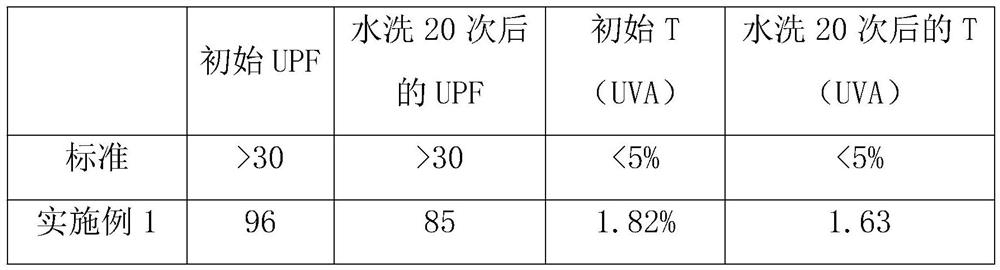

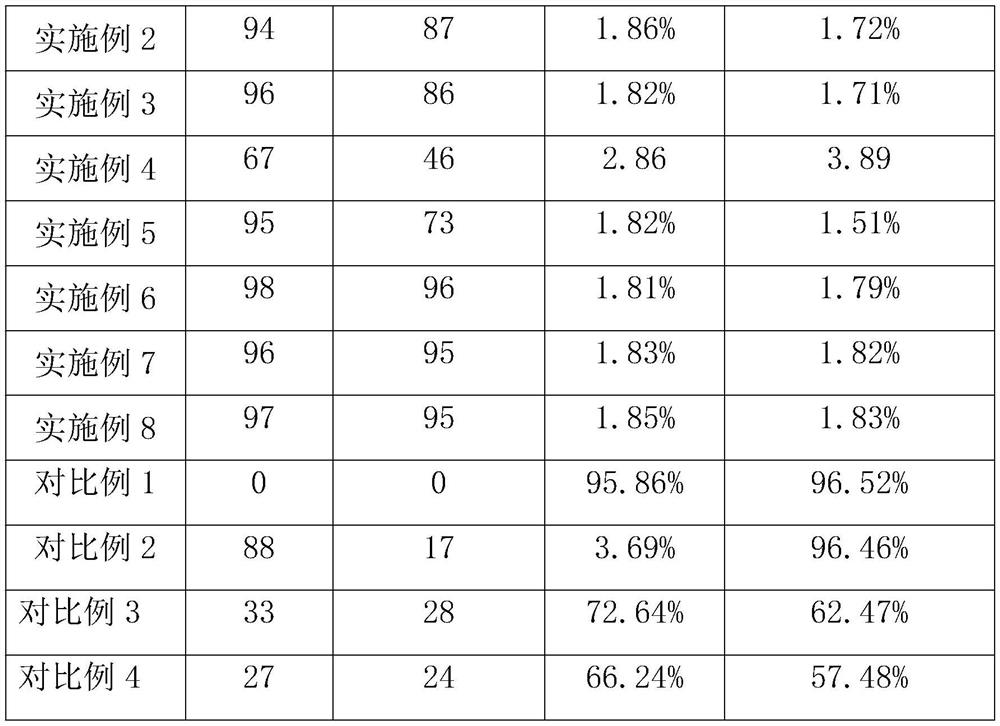

Embodiment 1

[0035] A new polyester-viscose yarn with high antibacterial and anti-ultraviolet rays is obtained by mixing polyester and viscose fibers at a mass ratio of 1:0.7. The treatment process of antibacterial and anti-ultraviolet new polyester viscose yarn is as follows:

[0036] Step (1), the preparation of purslane extract: get the fresh purslane of 10kg and dry in the incubator of 60 ℃, control the water content of purslane to be 20%, the purslane after drying is in crusher Crushing, control the average particle size of purslane extract to 40 mesh, add the crushed purslane extract and 70kg of water into the stirring tank, heat up to 80°C at a speed of 60r / min, and keep it warm for 10min. Then add 10 kg of ethanol and water with a mass ratio of 8:1 mixed solution as an extraction solvent, keep stirring at a speed of 60 r / min for 1 min, and then use a power of 100 W to extract 30 min at 35° C. to obtain a crude extract. Adding mass concentration to the crude extract is 3% hydrochlo...

Embodiment 2-3

[0040] The difference with embodiment 1 is: the input amount of each component is different.

Embodiment 4

[0042] The difference from Example 2 is that in step (1), the extraction solvent is ethanol and water at a mass ratio of 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com