Perovskite solar cell containing modification layer structure and preparation method thereof

A solar cell and modification layer technology, applied in the field of solar cells, can solve problems such as poor contact performance, degradation of photovoltaic device performance, and prone to holes, so as to improve charge extraction efficiency, facilitate large-area film formation, and promote interface contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

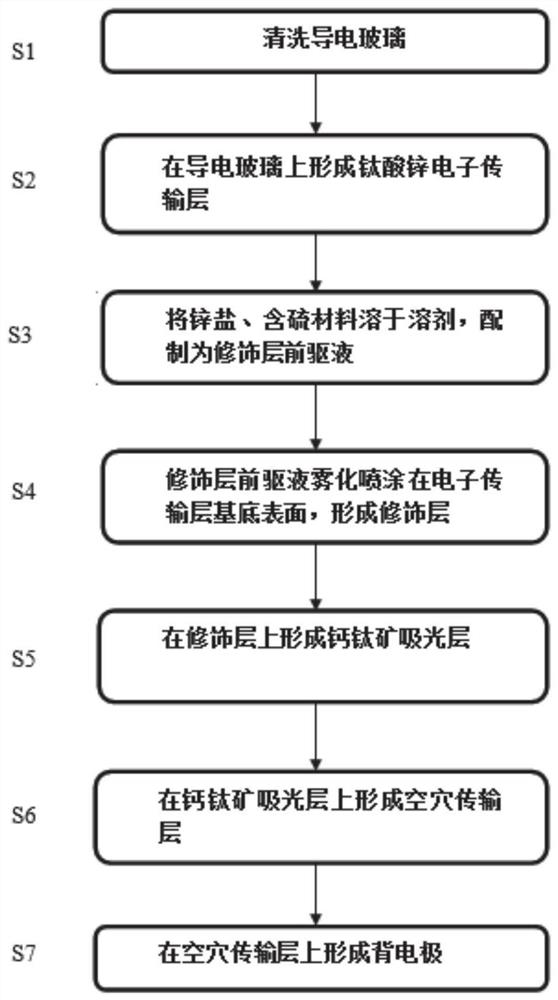

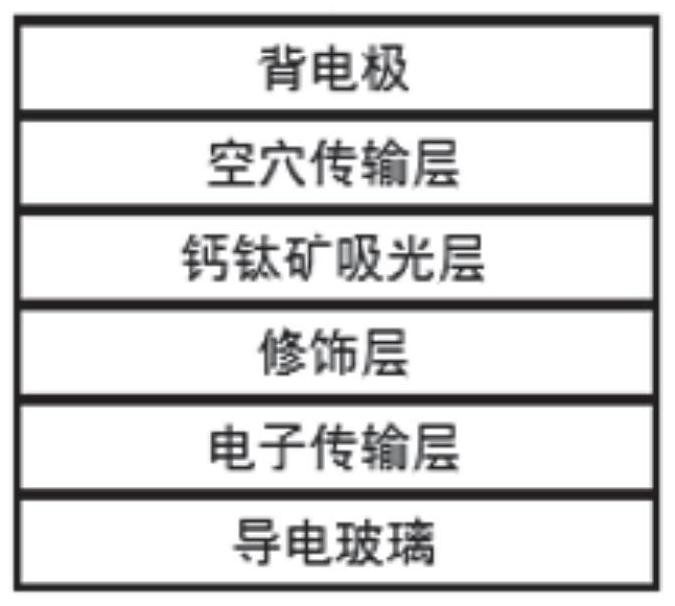

[0052] One aspect of the present invention provides a method for preparing a perovskite solar cell containing a modified layer structure, comprising the following steps:

[0053] S1: cleaning conductive glass;

[0054] S2: An electron transport layer is formed on the conductive glass, and the material of the electron transport layer is ZnTiO 3 ;

[0055] S3: prepare the modification layer precursor solution, dissolve the zinc salt in the solvent, add sulfur-containing material, stir and filter to obtain the modification layer precursor solution;

[0056] S4: Prepare a modified layer, atomize and spray the modified layer precursor solution obtained in step S3 on the surface of the electron transport layer substrate, keep warm, and cool to obtain a modified layer;

[0057] S5: forming a perovskite light-absorbing layer on the modified layer;

[0058] S6: forming a hole transport layer on the perovskite light absorbing layer;

[0059] S7: forming a back electrode on the hole ...

Embodiment 1

[0071] S1: Clean the conductive glass, use deionized water, acetone, and ethanol to ultrasonically clean the FTO conductive glass, 20 minutes each time.

[0072] S2: preparing the electron transport layer precursor solution, dissolving 0.01 mol / L titanium acetylacetonate and 0.01 mol / L zinc acetylacetonate in ethanol to obtain the electron transport layer precursor solution.

[0073] S3: Prepare the modification layer precursor solution, dissolve zinc acetate in ethanol at a concentration of 0.001mol / L; then add 0.0015mol / L ethanolamine and 0.0005mol / L thiourea, continue stirring until completely dissolved, and filter to obtain the modification layer precursor liquid.

[0074] S4: Spray the electron transport layer, heat the conductive glass to 450°C, atomize and spray the electron transport layer precursor liquid prepared in step S2 on the surface of the conductive glass, the amount of the sprayed precursor liquid is 20mL, and the liquid flow rate is 10mL / min, end Afterwards...

Embodiment 2

[0080] S1: Etching the conductive glass, etching the P1 track on the conductive glass.

[0081] S2: Clean the conductive glass, use deionized water, acetone, and ethanol to ultrasonically clean the FTO conductive glass, 20 minutes each time.

[0082] S3: preparing the electron transport layer precursor solution, dissolving 0.01 mol / L titanium acetylacetonate and 0.01 mol / L zinc acetylacetonate in ethanol to obtain the electron transport layer precursor solution.

[0083] S4: Prepare the modification layer precursor solution, dissolve zinc acetate in ethanol at a concentration of 0.001mol / L; then add 0.0015mol / L ethanolamine and 0.0005mol / L thiourea, continue stirring until completely dissolved, filter to obtain the modification layer precursor liquid.

[0084] S5: Spray the electron transport layer, heat the conductive glass to 450°C, atomize and spray the electron transport layer precursor solution prepared in step S3 on the surface of the conductive glass, the amount of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com