Nitrogen-doped carbon-supported non-noble metal nano-catalyst prepared based on MOF

A nano-catalyst, non-precious metal technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of complex preparation process, high energy consumption and poor stability of non-precious metal catalysts, and achieve excellent catalytic stability, good stability, The effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

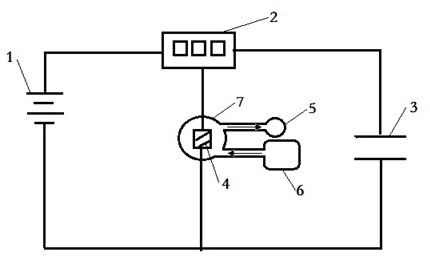

Method used

Image

Examples

Embodiment 1

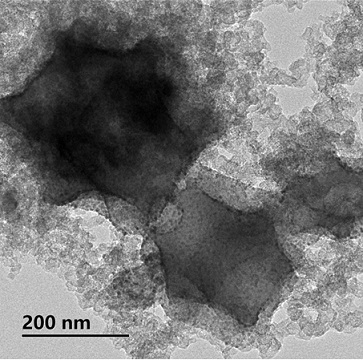

[0037] Preparation of nitrogen-doped carbon-supported Co catalyst

[0038] (1) Add 3g of Co(NO 3 ) 2 ·6H 2 O and 4.95g of 2-methylimidazole were dissolved in 150ml of methanol respectively and magnetically stirred for 30min, then the latter solution was slowly added to the former solution with a dropper, and then the mixed solution was magnetically stirred at room temperature for 4h. After completion, centrifuge at 10,000 rpm for 5 minutes and wash with methanol three times. Finally, place the cleaned MOF crystals in a vacuum drying oven at 70 °C for 24 hours to obtain a MOF precursor.

[0039] (2) Weigh 100mg of the prepared MOF precursor and 90mg of nano-carbon powder, add it to the sesame cake, add 50ml of absolute ethanol, put it into a magnet and seal it with magnetic stirring for 24 hours. Turn on the mixed slurry with magnetic stirring to volatilize the ethanol until the slurry is viscous and becomes a paste, and then spread the viscous precursor slurry on the 30cm ...

Embodiment 2

[0042] Preparation of nitrogen-doped carbon-supported CoO catalyst

[0043] (1) Add 3g of Co(NO 3 ) 2 ·6H 2 O and 4.95g of 2-methylimidazole were dissolved in 150ml of methanol respectively and magnetically stirred for 30min, then the latter solution was slowly added to the former solution with a dropper, and then the mixed solution was magnetically stirred at room temperature for 4h. After completion, centrifuge at 10,000 rpm for 5 minutes and wash with methanol three times. Finally, place the cleaned MOF crystals in a vacuum drying oven at 70 °C for 24 hours to obtain a MOF precursor.

[0044] (2) Weigh 104mg of the prepared MOF precursor and 86mg of nano-carbon powder, add it to the sesame cake, add 50ml of absolute ethanol, put it into a magnet and seal it with magnetic force for 24 hours. Turn on the mixed slurry with magnetic stirring to volatilize the ethanol until the slurry is viscous and becomes a paste, and then spread the viscous precursor slurry on the 30cm 2 ...

Embodiment 3

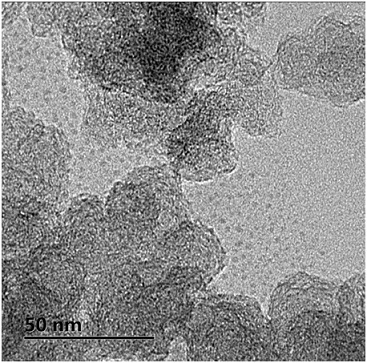

[0047] Preparation of nitrogen-doped carbon-supported CoFe catalyst

[0048] (1) Add 3g of Co(NO 3 ) 2 ·6H 2 O and 0.2 g of ferric sulfate were dissolved in 150 ml of methanol, 4.95 g of 2-methylimidazole was also dissolved in 150 ml of methanol, the two solutions were magnetically stirred for 30 min, and then the latter solution was slowly added with a dropper into the former solution, then magnetically stirred the mixed solution at room temperature for 6 h, centrifuged at 10,000 rpm for 5 min and washed with methanol for 3 times after the reaction was completed, and finally placed the cleaned MOF crystals in a vacuum oven for 70 °C for 24 hours to obtain the MOF precursor.

[0049] (2) Weigh 100mg of the prepared MOF precursor containing both Co and Fe and 90mg of nano-carbon powder, add it to the biscuit, add 50ml of absolute ethanol, put it into a magnet and seal it with magnetic force for 24 hours. Turn on the mixed slurry with magnetic stirring to volatilize the etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com