Process for reducing hardness of waste water by using carbon dioxide-containing waste gas

A carbon dioxide and waste water technology, applied in water softening, water treatment parameter control, chemical instruments and methods, etc., can solve problems such as increasing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

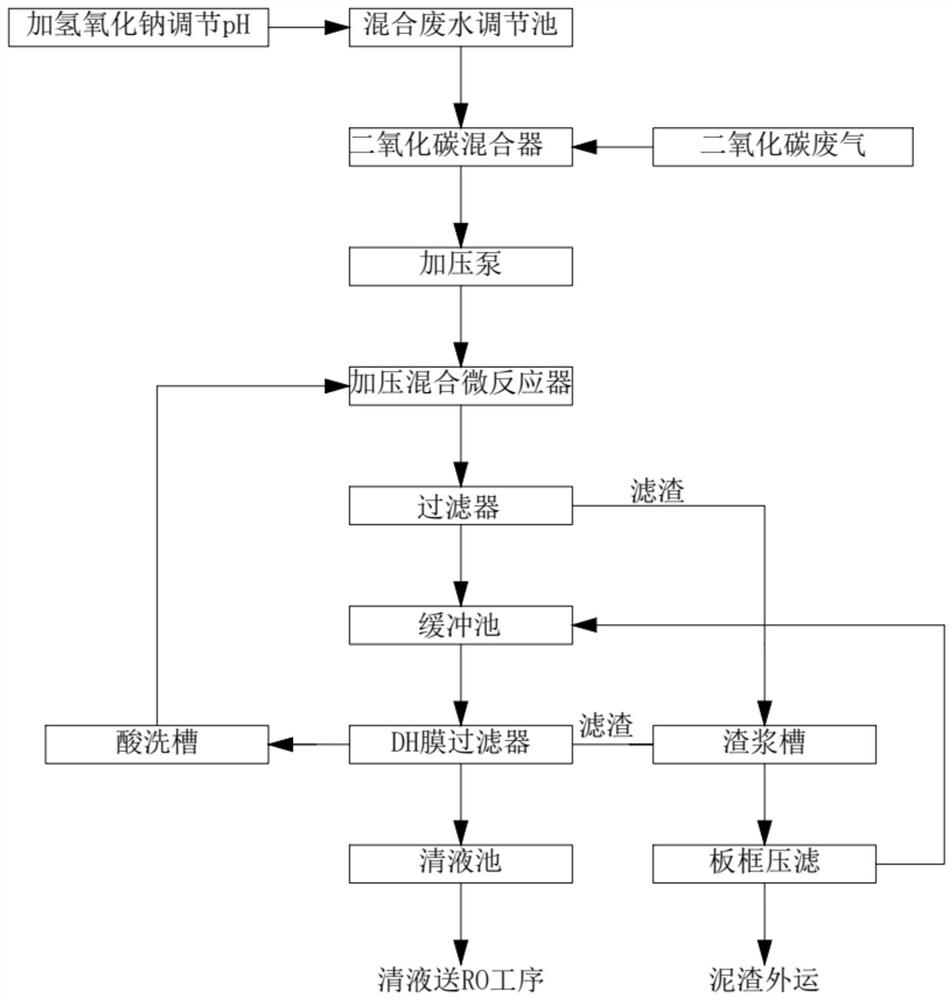

[0022] A process for reducing the hardness of waste water with carbon dioxide-containing waste gas, comprising the following steps:

[0023] 1) pH adjustment, sending the wastewater into the mixed wastewater adjustment tank, adding sodium hydroxide to adjust the pH of the wastewater to 11-12;

[0024] 2) The carbon dioxide hardness reduction reaction removes the hardness of the wastewater. The wastewater adjusted in step 1) is sent into the carbon dioxide mixer through a pressurized pump. The reaction is carried out in the pressurized mixing microreactor, and then the waste water flows out from the pressurized mixing microreactor and flows into the filter for filtration. device;

[0025] 3) Filtration, send the effluent of the filter in step 2) into the buffer pool, then into the DH membrane filter, and send the clear liquid obtained after filtering through the DH membrane filter into the clear liquid pool, and send it into the clear liquid pool through the clear liquid pool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com