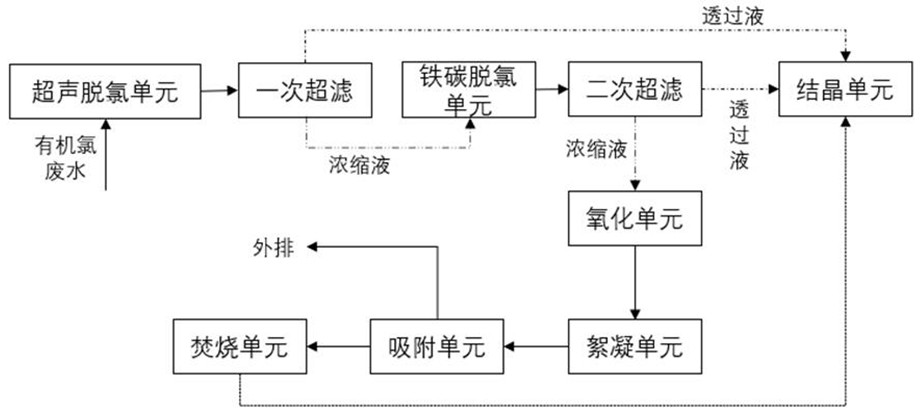

Staged treatment and resource recycling system for organic chlorine wastewater

A hierarchical treatment and recovery system technology, applied in the direction of water/sewage multi-stage treatment, mechanical oscillation water/sewage treatment, water/sewage treatment, etc., can solve problems such as low recycling rate, prolonged reaction process, and reduced degradation efficiency. Achieve the effect of reducing the concentration of chloride ions, reducing the treatment capacity and increasing the concentration of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The pretreated organic chlorine wastewater contains 89mg / L of carbon tetrachloride;

[0023] The organic chlorine wastewater is treated by an ultrasonic dechlorination unit, the ultrasonic frequency is 25kHz, and the sound intensity is 35W / cm 2 , the hydraulic retention time is 12min, and the concentration of carbon tetrachloride is reduced to 1.3mg / L; the concentration of organic chlorine compounds after one ultrafiltration concentration is 127.2mg / L, and it enters the iron-carbon dechlorination unit for treatment. After the hydraulic retention time is 23min, the organic chlorine The concentration is reduced to 2.3mg / L, continue to be concentrated by secondary ultrafiltration, and then transported to the oxidation unit for oxidation treatment of organic chlorine wastewater. After treatment by the oxidation unit, the concentration of organic chlorine in the effluent is 0.42mg / L. After subsequent treatment by the flocculation unit and the adsorption unit , dehydrate the ...

Embodiment 2

[0025] The pretreated organic chlorine wastewater contains 89mg / L of carbon tetrachloride;

[0026] The organochlorine wastewater was treated by an ultrasonic dechlorination unit, the ultrasonic device was not turned on, the hydraulic retention time was 12 minutes, and the concentration of carbon tetrachloride was reduced to 4.3mg / L; the concentration of organochlorine compounds after primary ultrafiltration concentration was 143.2mg / L , enter the iron-carbon dechlorination unit for treatment, after the hydraulic retention time is 23 minutes, the concentration of organic chlorine is reduced to 6.3 mg / L, and after continuing to be concentrated by ultrafiltration, it is transported to the oxidation unit for oxidation treatment of organic chlorine wastewater. After the treatment of the oxidation unit, the concentration of organic chlorine in the effluent is 0.98mg / L, after subsequent treatment by the flocculation unit and the adsorption unit, the sediment of the adsorption unit an...

Embodiment 3

[0028] The concentration of organic chlorine in the concentrated medical organic chlorine wastewater after pretreatment (air flotation, oil separation) is 0.63wt%;

[0029] The organic chlorine wastewater is treated by an ultrasonic dechlorination unit, the ultrasonic frequency is 25kHz, and the sound intensity is 35W / cm 2 , the hydraulic retention time is 12min; the concentration of organic chlorine compounds after the first ultrafiltration concentration is 1.72wt%, and it enters the iron-carbon dechlorination unit for treatment. After the hydraulic retention time is 23min, the organic chlorine concentration is reduced to 0.03wt%, and the second ultrafiltration concentration is continued After that, it is sent to the oxidation unit to oxidize the organic chlorine wastewater. After the oxidation unit is treated, the organic chlorine concentration in the effluent is 0.01wt%. After subsequent treatment by the flocculation unit and the adsorption unit, the sediment of the adsorpti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sound intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com