Device and method for improving biological treatment efficiency of trademark fabric production wastewater

A technology for biological treatment and production of wastewater, applied in the field of environmental protection, can solve problems such as high sludge output, low treatment efficiency, and large consumption of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for improving the biological treatment efficiency of trademark fabric production wastewater, comprising the following steps:

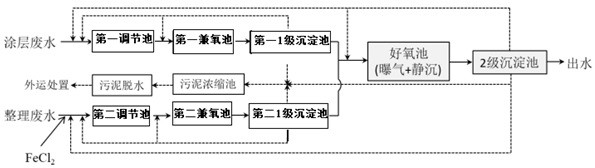

[0038] (1) A trademark cloth production enterprise produces 450 t / d of finishing waste water in the production process, with a COD of about 4500 mg / L and a pH of 12, and a coating waste water of 500 t / d with a COD of about 2500 mg / L , the pH is 7.0, and the total antimony concentration is 2 mg / L. Such as figure 1 As shown, the finishing wastewater and coating wastewater are pretreated in the regulating tank-facultative tank-first-stage sedimentation tank respectively. Clean up the wastewater and add FeCl to the influent of the adjustment tank 2 , the dosage is 1.1 kg / t waste water. The hydraulic retention time of the coating wastewater in the regulating tank and the facultative tank were 24 h and 24 h, respectively. The hydraulic retention time of the treated wastewater in the regulating tank and the facultative tank were 32 h and 4...

Embodiment 2

[0044] A method for improving the biological treatment efficiency of trademark fabric production wastewater, comprising the following steps:

[0045] A trademark fabric manufacturer discharges 300 tons of coating wastewater and 300 tons of finishing wastewater every day. Such as figure 1 As shown, the COD of the finishing waste water is 4800 mg / L, the COD of the coating waste water is 3000 mg / L, and FeCl 2 The dosage is 1.3 kg / t wastewater, FeCl 2 The final pH was 10.6. The hydraulic retention time of the finishing wastewater in the regulating tank and the facultative tank are 48 h and 60 h respectively, and the pH of the effluent from the first-stage sedimentation is 8.2. The hydraulic retention time of the coating wastewater in the regulating tank and the facultative tank were 24 h and 32 h, respectively. 35% of the sludge in the first-level sedimentation tank of the coating wastewater is returned to the regulating tank, 20% is returned to the facultative tank, and 45% i...

Embodiment 3

[0047] use as figure 1 A treatment device for biological treatment to improve the biological treatment efficiency of trademark fabric production wastewater, including the following steps: Step 1): finishing wastewater and coating wastewater are subjected to quality-based pretreatment in a regulating tank, a facultative tank and a first-grade sedimentation tank respectively , add an appropriate amount of FeCl to the influent of the adjustment tank for wastewater treatment 2 ; Step 2): The sludge in the first-stage sedimentation tank in the two pretreatment processes is returned to the regulating tank and the facultative tank respectively, and part of it is discharged into the sludge thickening tank, and the sludge is dehydrated and then transported for disposal; Step 3) : Discharge the effluent from the first-stage sedimentation tank of the two pretreatment processes into the aerobic tank. The aerobic tank adopts the operation mode of combining aeration and static sedimentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com