Baffling type ozone pre-oxidation combined biological filter advanced treatment method

An advanced treatment, combined biological technology, applied in the directions of oxidized water/sewage treatment, aerobic process treatment, chemical instruments and methods, etc., can solve the problems of reducing operating costs, unfavorable device utilization efficiency, short contact time, etc. The effect of liquid mixing and mass transfer, reducing ozone dosage, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

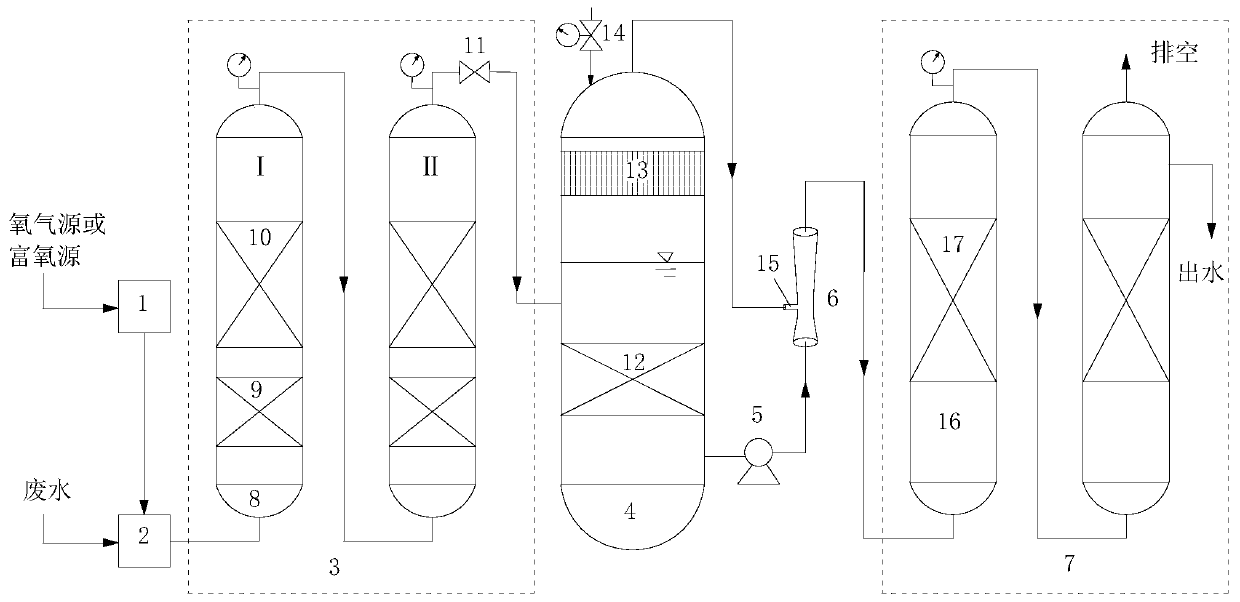

[0025] A petrochemical company in Shaanxi Province adopted a dual-membrane system for wastewater reuse after treatment of refining and chemical wastewater. Among them, the reverse osmosis concentrated water produced was about 1200m 3 / d, reverse osmosis concentrated water contains a large amount of refractory substances, the company currently uses ozone catalytic oxidation process for treatment, the dosage of ozone is between 60-80mg / L, the ozone consumption is relatively large, the cost is high, and the quality of effluent water fluctuates Larger, it is difficult to meet the local emission standard COD ≤ 50mg / L, the company plans to upgrade the existing process to achieve cost reduction and efficiency increase to meet actual production needs. Using the baffle type ozone pre-oxidation combined biological filter process of the present invention to carry out on-site advanced treatment pilot test of on-site reverse osmosis concentrated water, the scale of the pilot test is 24m 3 ...

Embodiment 2

[0028] Chemically synthesized wastewater from a chemical company in Hainan Province, with a daily treatment capacity of 8600m 3 / d, at present, the process of anaerobic hydrolytic acidification + oxidation ditch + biological aerated filter is used for wastewater treatment, but because the wastewater contains a large amount of phenols and naphthalene rings, the process at the end of the wastewater is unstable and the effluent fluctuates greatly , the company plans to upgrade the existing biological aerated filter process to improve the water quality and stability of the effluent. The baffle type ozone pre-oxidation combined biological filter of the present invention is used for advanced treatment, and a 50L / h scale small-scale test is carried out. The hydraulic retention time of wastewater in the ozone pre-oxidation unit, stabilization tower and biological treatment unit is controlled at 20min, 2h and 3.5h respectively. The ozone pre-oxidation unit is connected in series with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com