Method for greatly improving surface hardness of zirconium-based amorphous alloy through laser irradiation

A zirconium-based amorphous alloy, surface hardness technology, applied in metal material coating process, coating, solid diffusion coating and other directions, to achieve the effect of simple method, high efficiency and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This example is used to illustrate the method of greatly improving the surface hardness of zirconium-based amorphous alloy by laser irradiation of the present invention.

[0033] Choose a Zr41.2Ti13.8Cu12.5Ni10Be22.5 amorphous alloy block with a thickness of 2 mm, and polish the surface, use 400, 800, 1200 and 2000 sandpaper to polish, and then polish with 0.5 micron diamond particle polishing paste To mirror smooth, clean the surface with alcohol. Place the block sample in a cuboid cavity that can be fed with nitrogen, with the mirror facing upwards, using a nanosecond laser with a wavelength of 1064nm, a focused spot diameter of 43μm, and a pulse width of 10ns. Perform nanosecond laser treatment.

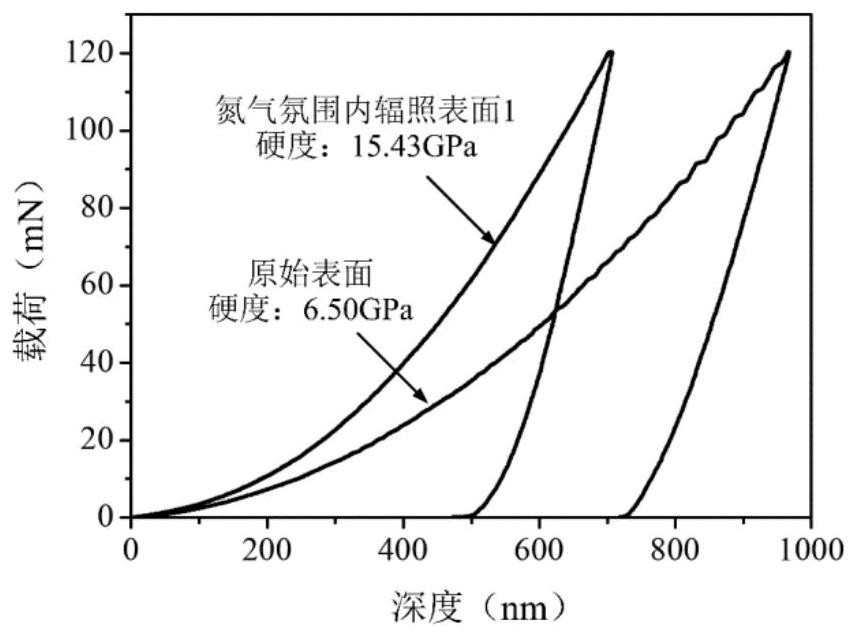

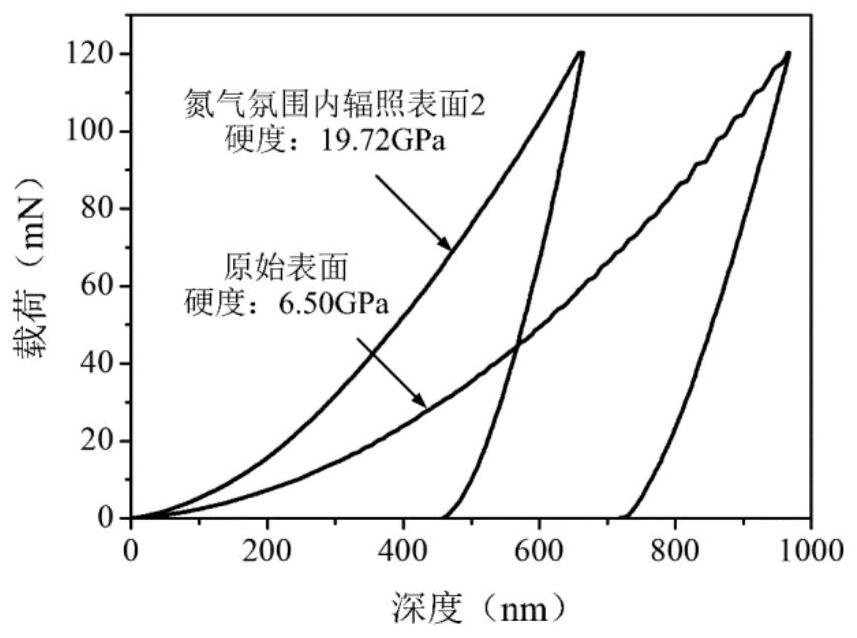

[0034] figure 2 After laser irradiation under the test conditions of average laser power of 12.1W, scanning speed of 10mm / s, overlapping rate of adjacent scanning lines of 10%, and laser irradiation times of 3, the surface after irradiation is obtained Compared with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com