Energy-saving oyster-based fiber composite layer and preparation process thereof

A technology of fiber compounding and preparation technology, which is applied in the direction of cellulose plastic layered products, fiber treatment, fiber chemical characteristics, etc., can solve the problems of high production cost of oyster fiber, and achieve comfortable touch, good elasticity and support, and low energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

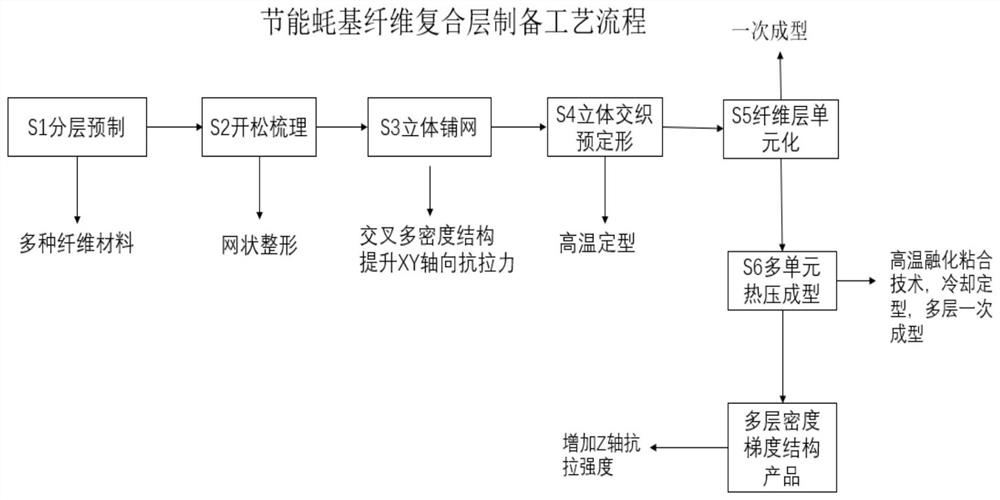

[0043] Preparation process flow of the energy-saving oyster-based fiber complex layer of the present invention Figure 1 Down:

[0044] Include the following steps:

[0045] S1 layered prefabrication: Making oyster-based fiber layer, viscose wire fiber layer, multi-block polyurethane fiber layer, rich fibrous fiber layer, natural latex wire fiber layer, and viscose short fiber fiber layer;

[0046] S2 begins to combat: the above fiber layers are made and sorted, and the soft structure is formed;

[0047] S3 stereo net: The above-mentioned fiber layer is sequentially subjected to oyster-based fibers, adhesive wire, multi-block polyurethane fibers, rich fibers, natural latex wire, and viscose short fibers. Locus cell fiber layer A;

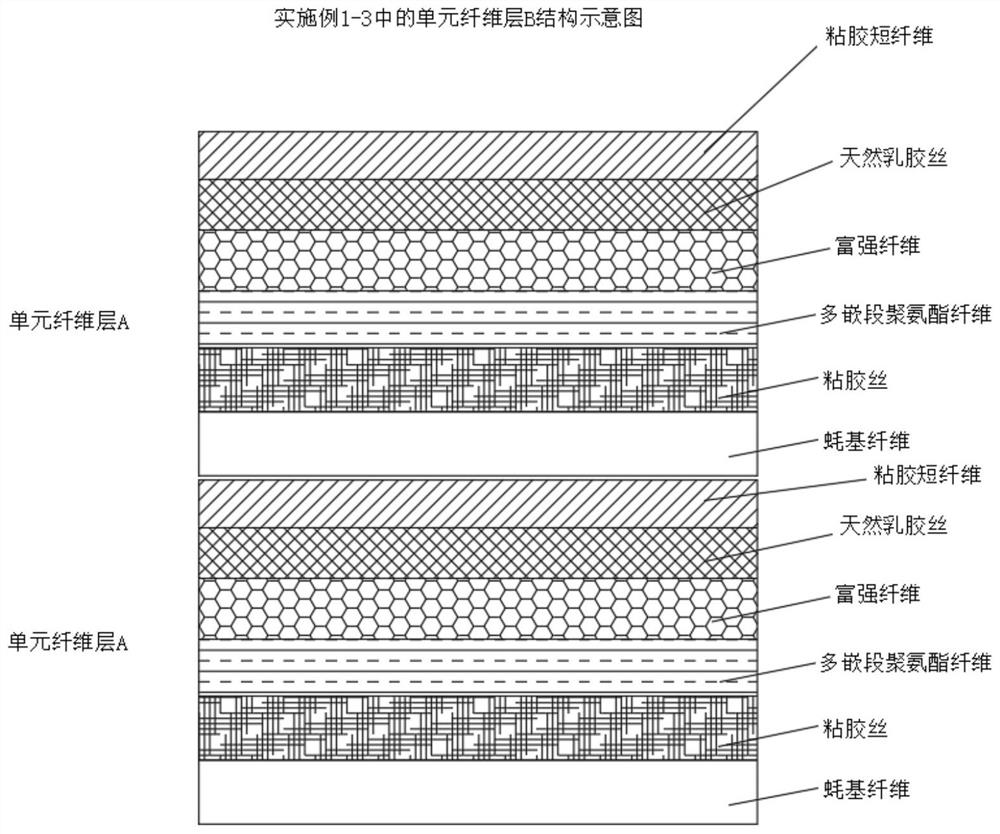

[0048]S4 stereo interleaves: Stack 2 of the unit fiber layer together, form a unit fiber layer B, in the case where pressure is not applied, placed in an oven, high temperature predetermined type;

[0049] S5 fiber layer unitization: After cooling the un...

Embodiment 1

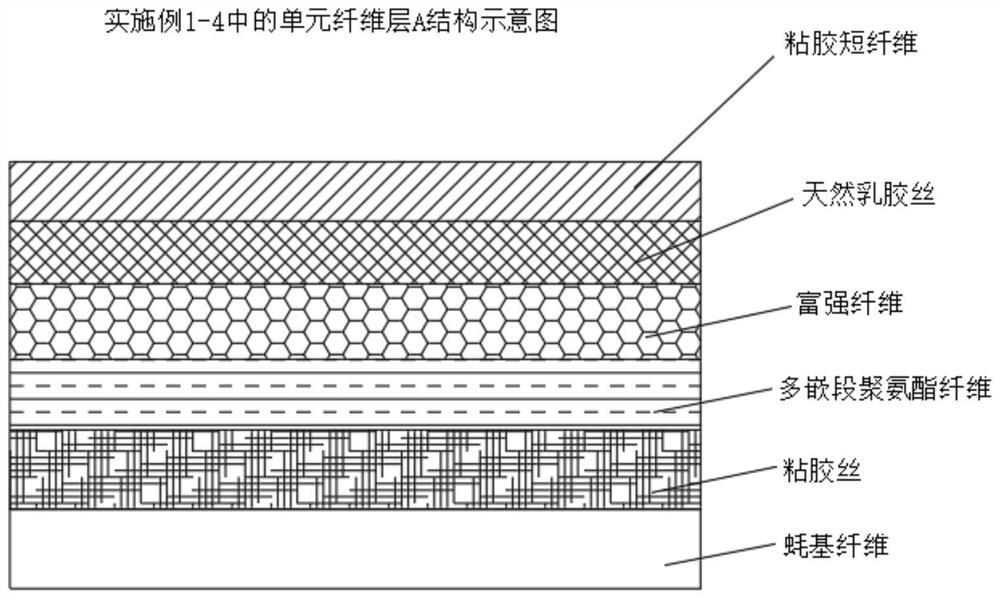

[0064] Append Figure 2 , 3 A energy-saving oyster-based fiber composite layer shown in 5, the oyster-based fiber composite layer includes elastomeric fibers and bonding fibers; the elastomeric fibers and the mass ratio of the binder fibers are 3: 1, The elastomeric fibers include oyster-based fibers that account for 30% of the elastomeric fibers, and the elastomeric fibers include natural latexes 40%, multi-block polyurethane fibers. 30% and oyster-based fibers; the bonding fibers include 50% viscose short fibers, 25% strong fibers, 25% of the viscous filaments; the energy-saving oyster-based fiber composite layer is stacked by several unit fibers a stack Based; the cell fiber layer A is sequentially sequentially oyster-based fiber, viscous wire, multi-block polyurethane fiber, rich fiber, natural latex wire and viscose short fibers.

[0065] The above-mentioned preparation process of the energy-saving oyster-based fiber complex layer includes the following steps:

[0066] S1 laye...

Embodiment 2

[0085] Append Figure 2 , 3 A energy-saving oyster-based fiber composite layer, the oyster-based fiber composite layer includes an elastomeric fiber and a bonding fiber; the elastomeric fibers and the bonded moiety of 2: 1, the elastomer The fibers include oyster-based fibers that account for 40% of the elastomeric fibers, according to their respective weight percent, including natural latex wire 30%, multi-block polyurethane fiber 30% and 40% of the oyster-based fiber; the binder fibers include 50% viscose short fibers, 25% rich in fibers, 25% of the viscous filaments; the energy-saving oyster-based fiber composite layer is stacked by several unit fiber layer A. The unit fiber layer A is sequentially sequentially oyster, viscous wire, multi-block polyurethane fiber, rich fiber, natural latex wire and viscose short fibers.

[0086] The above-mentioned preparation process of the energy-saving oyster-based fiber complex layer includes the following steps:

[0087] S1 layered prefabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com