Enhanced CFBR process applied to treatment of wig wastewater containing high ammonia nitrogen

A technology for wastewater treatment and high ammonia nitrogen, which is applied in natural water treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of high operating cost and energy consumption, low ammonia nitrogen and total nitrogen removal efficiency, etc. problem, to achieve the effect of reducing processing cost and energy consumption, low processing cost and energy consumption, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

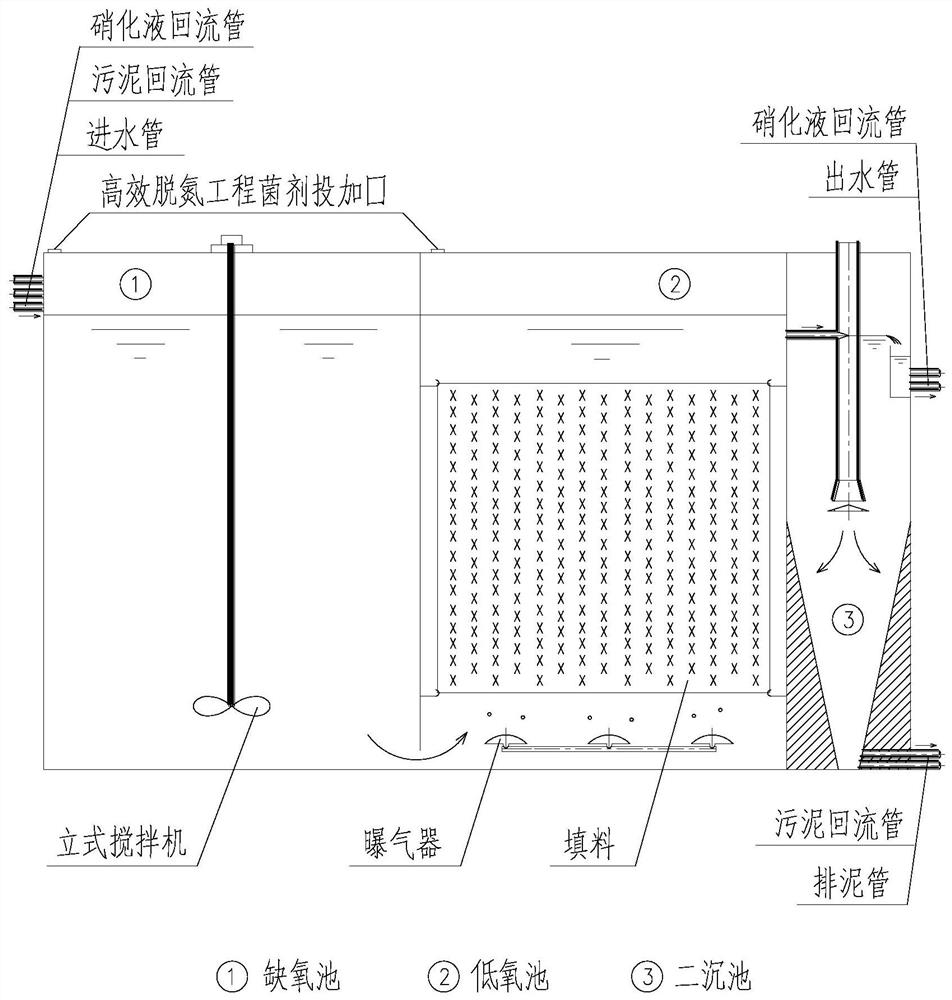

[0030] In this example, the FDN-01 and FDN-02 strains were inserted into LB liquid medium, and after being expanded and cultivated in a shaker for 3 days, an efficient denitrification engineering bacterial agent was prepared. The water volume of high ammonia nitrogen wig wastewater is 8 m 3 / d, the water temperature is 25°C, the pH is 8.1, the initial concentration of COD is 386 mg / L, the initial concentration of ammonia nitrogen is 480 mg / L, the initial concentration of nitrate nitrogen is 59 mg / L, and the initial concentration of nitrite nitrogen is 0.6 mg / L, the initial concentration of total nitrogen was 600 mg / L. Add 2000 mL of high-efficiency denitrification engineering bacteria to the anoxic tank and hypoxic tank of the "CFBR treatment device", respectively, and the MLSS concentration is about 3000 mg / L. After the activated sludge in the anoxic tank and the low-oxygen tank were co-cultivated with high-efficiency denitrification engineering bacteria for 7 days, the wig...

Embodiment 2

[0033] In this example, the FDN-01 and FDN-02 strains were inserted into LB liquid medium, and after being expanded and cultivated in a shaker for 3 days, an efficient denitrification engineering bacterial agent was prepared. The water volume of high ammonia nitrogen wig wastewater is 5.5 m 3 / d, the water temperature is 18°C, the pH is 7.4, the initial concentration of COD is 858 mg / L, the initial concentration of ammonia nitrogen is 262 mg / L, the initial concentration of nitrate nitrogen is 22 mg / L, and the initial concentration of nitrite nitrogen is 0.35 mg / L, the initial concentration of total nitrogen was 309 mg / L. Add 2000 mL of high-efficiency denitrification engineering bacteria to the anoxic tank and hypoxic tank of the "CFBR treatment device", and the MLSS concentration is about 2800 mg / L. After the activated sludge in the anoxic tank and the hypoxic tank were co-cultivated with high-efficiency denitrification engineering bacteria for 7 days, the wig wastewater wa...

Embodiment 3

[0036] In this example, the FDN-02 strain was inserted into LB liquid medium, and expanded culture was carried out in a shaker for 7 days to prepare a high-efficiency denitrification engineering bacterial agent. The water volume of high ammonia nitrogen wig wastewater is 2.0 m 3 / d, the water temperature is 4°C, the pH is 6.0, the initial concentration of COD is 184 mg / L, the initial concentration of ammonia nitrogen is 123 mg / L, the initial concentration of nitrate nitrogen is 38 mg / L, and the initial concentration of nitrite nitrogen is 15.6 mg / L, the initial concentration of total nitrogen was 190 mg / L. Add 1000 mL of high-efficiency denitrification engineering bacteria to the anoxic tank and hypoxic tank of the "CFBR treatment device", respectively, and the MLSS concentration is about 2500 mg / L. After the activated sludge in the anoxic tank and the hypoxic tank were co-cultivated with high-efficiency denitrification engineering bacteria for 7 days, the wig wastewater was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com