A kind of method for continuously preparing 4-chloro-1-butanol

A continuous method and butanol technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as increasing production costs, achieve less waste generation, reduce hazardous waste emissions, and improve dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

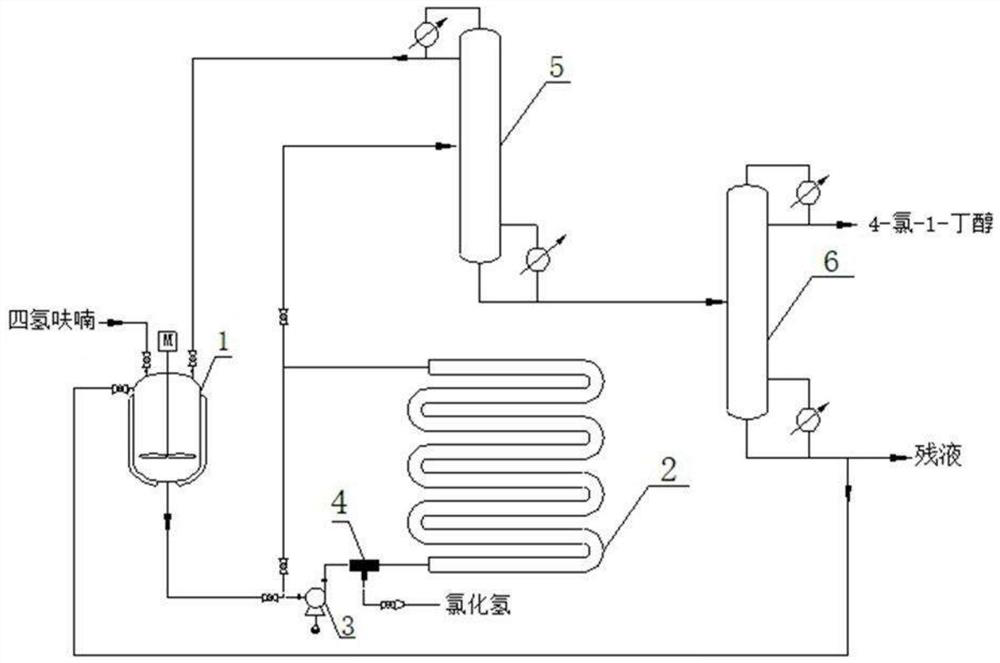

Image

Examples

Embodiment 1

[0024] The inner diameter of the intensified reactor is A 2.0m-long pipe reactor with extracorporeal pumping and circulation, and the internal packing is stainless steel θ packing; the preparation process of 4-chloro-1-butanol is as follows:

[0025] 1) THF is added into the enhanced reactor and preheated to 65°C;

[0026] 2) Raise the temperature of the intensified reactor to 95°C, then slowly feed the amount of hydrogen chloride into the reactor according to the molar ratio of tetrahydrofuran to hydrogen chloride of 1:0.31, and control the pressure of the reactor to 1.2MPa, and force a circular reaction. During the reaction, every 0.5h sampling analysis, stop the reaction when the THF conversion rate reaches 30%;

[0027] 3) Add the reaction solution obtained in step 2) to the first rectification tower, control the temperature of the first rectification tower tower bottom to be 35° C., and the pressure of the first rectification tower to be-0.067Mpa, and obtain hydrogen ch...

Embodiment 2

[0030] The difference between this embodiment and Example 1 is that, in step 3), the tetrahydrofuran fraction obtained at the top of the tower is mainly recycled to step (1) for reuse, and 75% of the raffinate in the second rectifying column is recycled to step ( 2) reuse, after the above-mentioned circular reaction is carried out once, 4-chloro-1-butanol is finally obtained at the top of the second rectifying tower, with a yield of 94% and a purity of 99.6%.

Embodiment 3

[0032] The difference between this example and Example 2 is that in step 2), the temperature of the enhanced reactor is raised to 98.5°C, and hydrogen chloride is fed into the enhanced reactor with a molar ratio of tetrahydrofuran to hydrogen chloride of 1:0.62 for forced circulation reaction and the reactor The pressure is 1.25MPa. During the reaction process, the sample is analyzed every 0.5h, and the reaction is stopped when the THF conversion rate reaches 60%. In step 3), the temperature in the bottom of the first rectification tower is 33.6°C, and the rectification pressure is -0.075MPa; In step 4), the temperature at the bottom of the second rectification tower is 70.8°C, and the rectification pressure is -0.098Mpa, and finally 4-chloro-1-butanol is obtained at the top of the second rectification tower with a yield of 95%. Its purity is 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com