A kind of self-lubricating sealing material and preparation method thereof

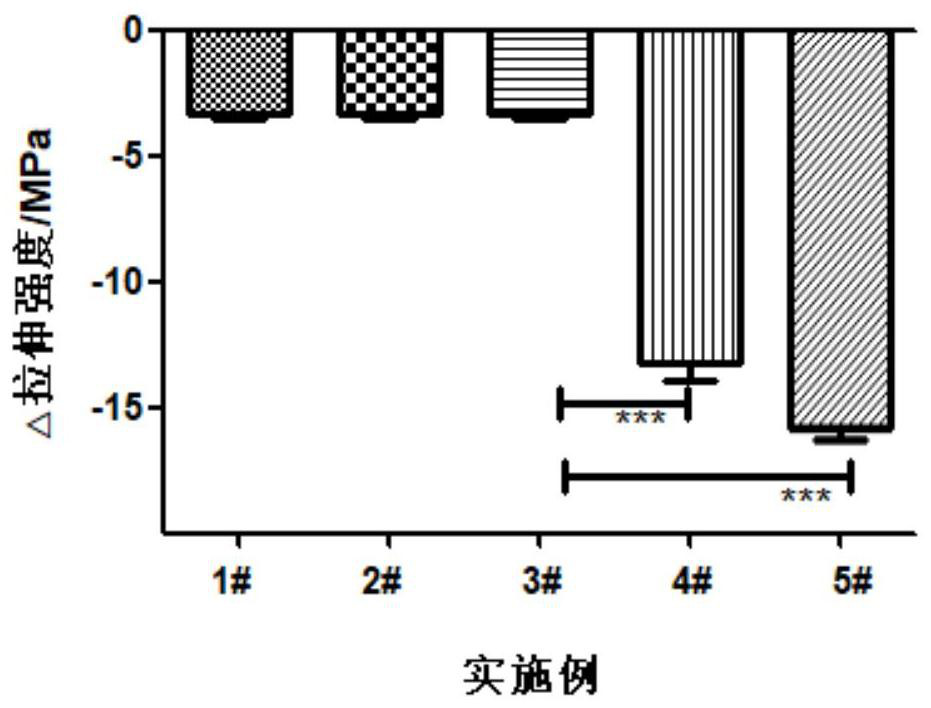

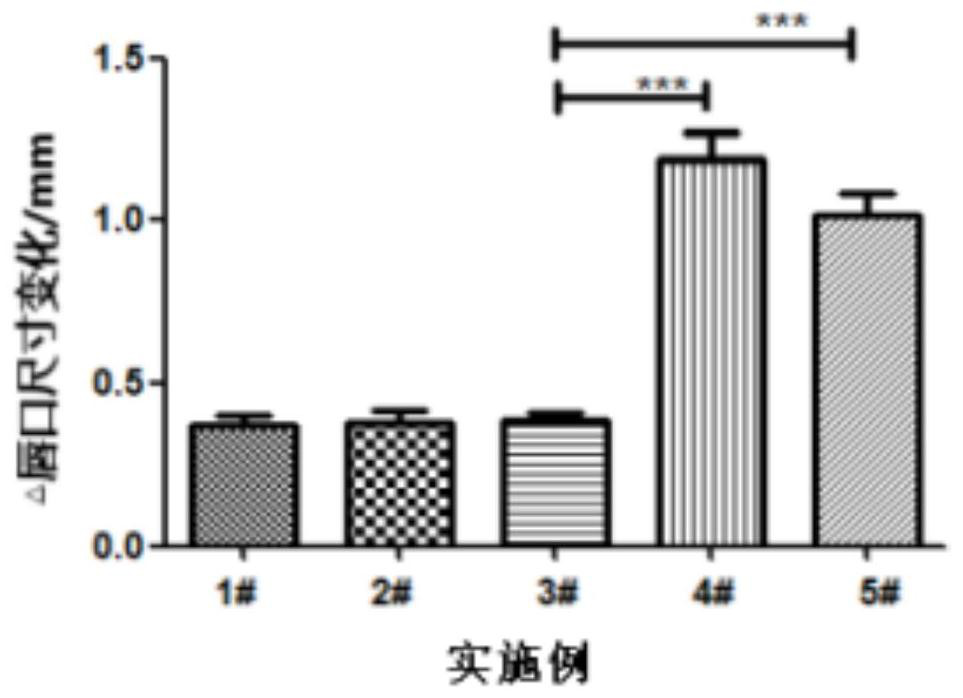

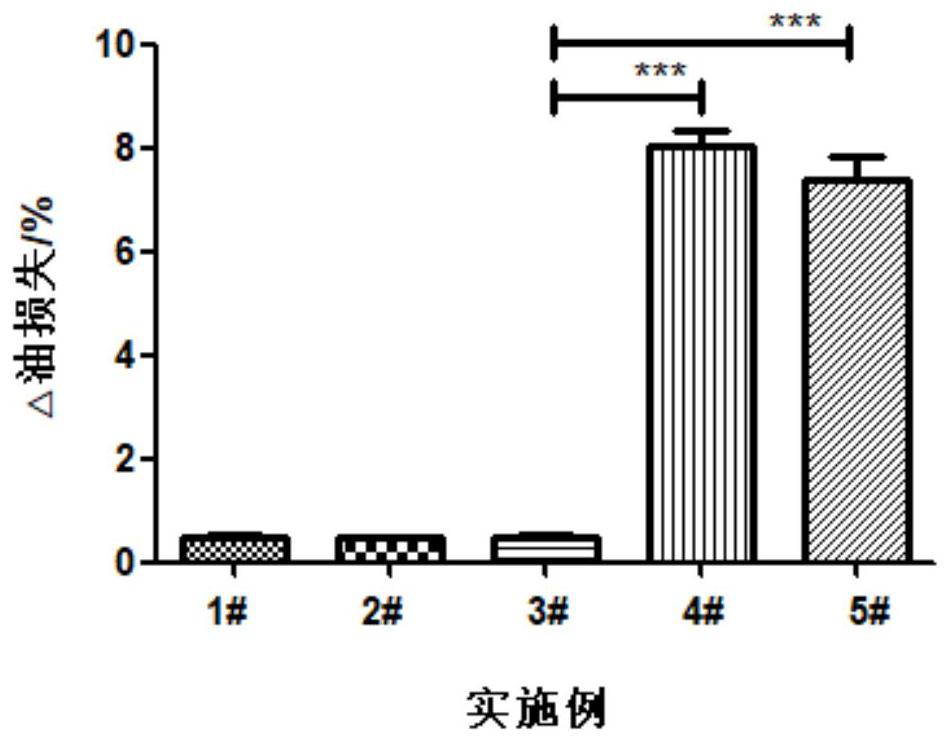

A sealing material and self-lubricating technology, which is applied in the field of self-lubricating sealing materials and its preparation, can solve the problems of failure of rubber products, reduce the friction coefficient of rubber products, and single use, so as to achieve less oil loss or gas loss and change in lip size Small, good elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step (1) Put 60 parts of nitrile rubber and 15 parts of octaethylene-cage silsesquioxane into the internal mixer, the temperature of the internal mixer is 80°C, the speed of the internal mixer is 50r / min, and the processing time is 10min , to obtain modified nitrile rubber.

[0043] Step (2) Dissolve aminopropyl POSS and maleic anhydride in toluene, the molar ratio of POSS to maleic anhydride is 1.01:1, react at 80°C for 24 hours, separate and purify to obtain POSS-MA;

[0044] Step (3) Dissolve POSS-MA, polyethylene glycol, and p-toluenesulfonic acid in toluene. The molar ratio of POSS-MA and polyethylene glycol is 1:1.01, and p-toluenesulfonic acid accounts for 0.01% of the total mass of ethylene glycol, separated and purified after reacting at 120°C for 24 hours to obtain POSS-MA-PEG;

[0045] Step (4) Weigh 0.1 part of POSS-MA-PEG, 0.5 part of silicone oil, 0.01 part of N, N-methylenebisacrylamide according to parts by weight, dissolve POSS-MA-PEG in acetone, add s...

Embodiment 2

[0052] Step (1) Put 80 parts of nitrile rubber and 30 parts of octaethylene-cage silsesquioxane into the internal mixer, the temperature of the internal mixer is 135°C, the speed of the internal mixer is 100r / min, and the processing time is 25min , to obtain modified nitrile rubber.

[0053] Step (2) Dissolve aminopropyl POSS and maleic anhydride in toluene, the molar ratio of POSS to maleic anhydride is 1.05:1, react at 100°C for 36 hours, separate and purify to obtain POSS-MA;

[0054] Step (3) Dissolve POSS-MA, polyethylene glycol, and p-toluenesulfonic acid in toluene, the molar ratio of POSS-MA and polyethylene glycol is 1:1.05, p-toluenesulfonic acid accounts for POSS-MA and poly 1% of the total mass of ethylene glycol, separated and purified after reacting at 140°C for 36 hours to obtain POSS-MA-PEG;

[0055] Step (4) Weigh 2 parts of POSS-MA-PEG, 20 parts of lubricating oil 100SN, 2 parts of polyethylene glycol diacrylate, dissolve POSS-MA-PEG in acetone, add 100SN an...

Embodiment 3

[0062] Step (1) Put 70 parts of nitrile rubber and 20 parts of octaethylene-cage silsesquioxane into the internal mixer, the temperature of the internal mixer is 110°C, the speed of the internal mixer is 80r / min, and the processing time is 20min , to obtain modified nitrile rubber.

[0063] Step (2) Dissolve aminopropyl POSS and maleic anhydride in toluene, the molar ratio of POSS to maleic anhydride is 1.03:1, react at 90°C for 30 hours, separate and purify to obtain POSS-MA;

[0064] Step (3) Dissolve POSS-MA, polyethylene glycol, and p-toluenesulfonic acid in toluene, the molar ratio of POSS-MA and polyethylene glycol is 1:1.03, p-toluenesulfonic acid accounts for POSS-MA and poly 0.15% of the total mass of ethylene glycol, separated and purified after reacting at 130°C for 30 hours to obtain POSS-MA-PEG;

[0065] Step (4) Weigh 0.5 parts of POSS-MA-PEG, 5 parts of lubricating oil 70SN, 0.08 parts of N, N-methylenebisacrylamide, dissolve POSS-MA-PEG in acetone, add 70SN an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com