Coal mine roadway spraying material and preparation method thereof

A spraying material and roadway technology, applied in anti-corrosion coatings, fire-proof coatings, cement coatings, etc., can solve problems such as easy water absorption and deliquescence or expansion, great influence of coating dust, gas gushing out of gobs, etc., to achieve high toughness and elasticity , good support and high support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

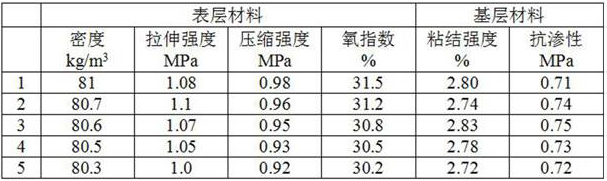

Examples

Embodiment 1

[0026] A coal mine roadway spraying material, comprising a base layer and a surface layer, the base layer is made of the following raw materials in parts by weight: 25 parts of 42.5 Portland cement, 35 parts of fly ash, 8 parts of clay, and 4 parts of latex powder , 15 parts of fiber reinforced material, 0.2 part of styrene-acrylic emulsion, 0.2 part of polyvinyl alcohol, 1 part of water glass and 35 parts of water, and the surface layer is a polyurethane foam layer.

[0027] The polyurethane layer is made of the following raw materials in parts by weight: 100 parts of polyether polyol (2000), 17.5 parts of toluene diisocyanate, 3 parts of phenolic resin, 8 parts of dimethyl silicone oil, 1 part of diethylene glycol, catalyst 1 part, 1.5 parts of trimethylolpropane, 10 parts of hollow glass microspheres, 12 parts of fiber reinforced material, 5 parts of water glass and 3 parts of deionized water.

[0028] The catalyst is a mixture of dibutyltin dilaurate and triethylenediamine...

Embodiment 2

[0036] A coal mine roadway spraying material, comprising a base layer and a surface layer, the base layer is made of the following raw materials in parts by weight: 28 parts of Portland cement, 32 parts of fly ash, 9 parts of clay, 5 parts of latex powder, 14 parts of fiber reinforced materials, 0.22 parts of styrene-acrylic emulsion, 0.18 parts of polyvinyl alcohol, 1.2 parts of water glass and 38 parts of water, and the surface layer is a polyurethane layer.

[0037] The polyurethane layer is made of the following raw materials in parts by weight: 100 parts of polyether polyol (2000), 17.5 parts of toluene diisocyanate, 4 parts of phenolic resin, 8.5 parts of dimethyl silicone oil, 1.2 parts of diethylene glycol, catalyst 1.2 parts, 1.4 parts of trimethylolpropane, 11 parts of hollow glass microspheres, 11 parts of fiber reinforced material, 6 parts of water glass and 3.5 parts of deionized water.

[0038] The catalyst is a mixture of dibutyltin dilaurate and triethylenediam...

Embodiment 3

[0043] A coal mine roadway spraying material, comprising a base layer and a surface layer, the base layer is made of the following raw materials in parts by weight: 30 parts of Portland cement, 30 parts of fly ash, 10 parts of clay, 6 parts of latex powder, 13 parts of fiber reinforced materials, 0.25 parts of styrene-acrylic emulsion, 0.15 parts of polyvinyl alcohol, 1.5 parts of water glass and 30 parts of water, and the surface layer is a polyurethane layer.

[0044] The polyurethane layer is made of the following raw materials in parts by weight: 100 parts of polyether polyol (2000), 17.5 parts of toluene diisocyanate, 5 parts of phenolic resin, 9 parts of dimethyl silicone oil, 1.5 parts of diethylene glycol, catalyst 1.5 parts, 1.2 parts of trimethylolpropane, 12 parts of hollow glass microspheres, 10 parts of fiber reinforced material, 6.5 parts of water glass and 4 parts of deionized water.

[0045] The catalyst is a mixture of dibutyltin dilaurate and triethylenediami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com