A kind of preparation method of anionic fluorescent fatliquoring agent

An anionic, fatliquor technology, applied in the field of leather chemicals, to achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

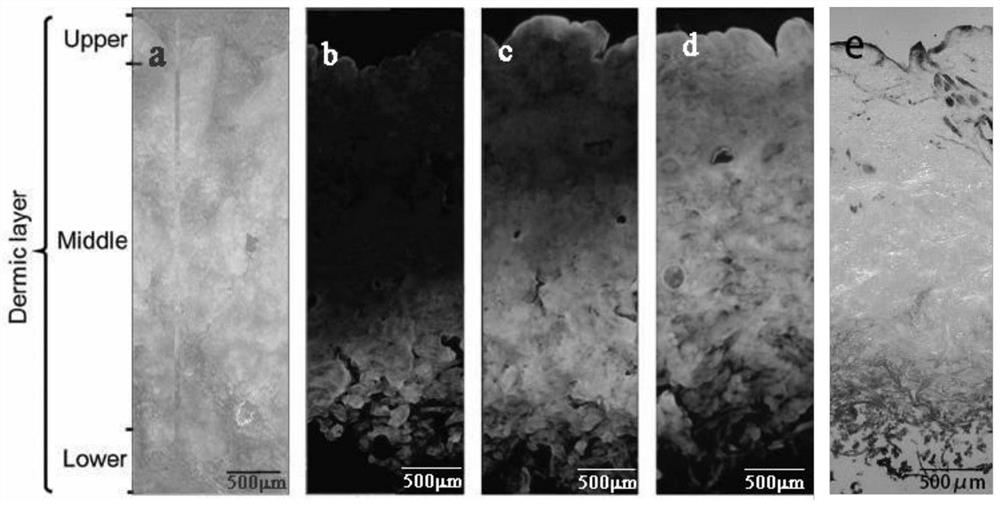

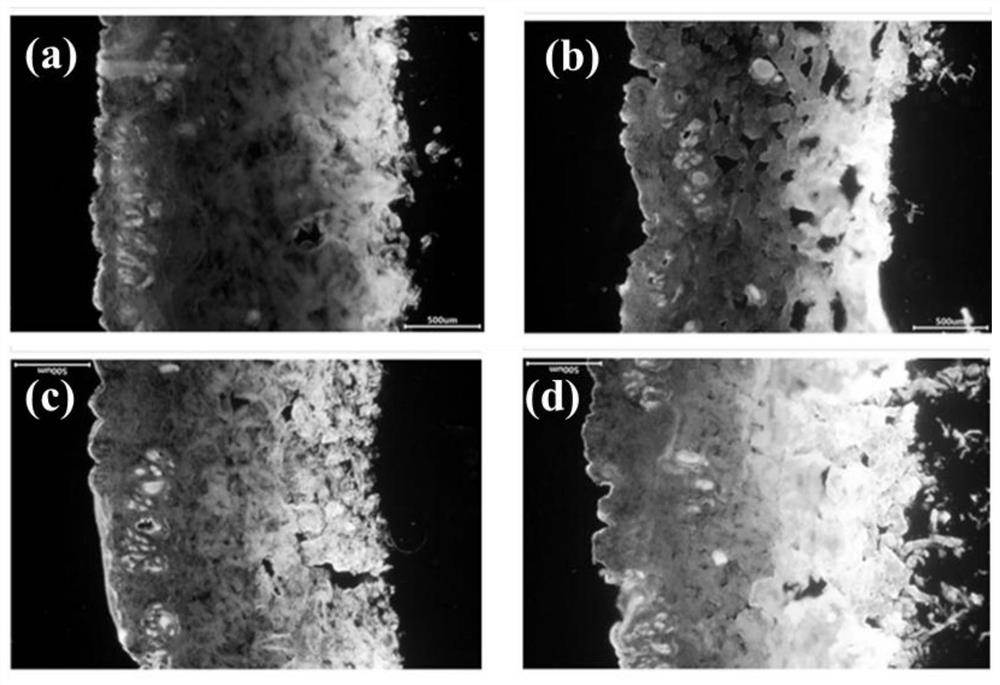

Image

Examples

Embodiment 1

[0026] Take 100 parts of castor oil, add 19.6 parts of maleic anhydride, and react at 105° C. for 3 hours to obtain intermediate product A. Add 1.2 parts of A to 50 parts of dimethylformamide, then add 0.35 parts of 5-aminofluorescein and 0.48 parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, Reaction at 40 ° C for 5 h to obtain product B. B was added to 100 parts of dichloromethane, and then 50 parts of water was added, and the mixture was evenly mixed and then left to stand for layers. Collect the organic phase, then add 100 parts of water, mix well, and then let stand for layers. The organic phase was collected, 150 parts of water was added, mixed evenly and then left to stand for layers, the organic phase was collected, and the dichloromethane was removed by rotary evaporation under reduced pressure to obtain product C. Take 1 part of C, add 5 parts of ethylene glycol monobutyl ether, mix evenly, and then add 100 parts of commercial anionic fatliquor ...

Embodiment 2

[0028] Take 50 parts of natural phospholipids and 50 parts of castor oil, add 20 parts of itaconic anhydride, and react at 85°C for 4 hours to obtain intermediate product A. Add 1.2 parts of A to 25 parts of dimethyl sulfoxide, then add 0.35 parts of 5-aminofluorescein and 0.48 parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, in Reaction at 20°C for 10h to obtain product B. B was added to 50 parts of dichloromethane, and then 50 parts of water was added, and the mixture was evenly mixed, and then allowed to stand for layers. Collect the organic phase, then add 100 parts of water, mix well, and then let stand for layers. The organic phase was collected, 150 parts of water was added, mixed evenly and then left to stand for layers, the organic phase was collected, and the dichloromethane was removed by rotary evaporation under reduced pressure to obtain product C. Take 1 part of C, add 10 parts of ethylene glycol monobutyl ether, mix evenly, and then add 20...

Embodiment 3

[0030] Take 40 parts of stearic acid monoglyceride, add 15 parts of succinic anhydride, and react at 90°C for 2 hours to obtain intermediate product A. Take 1 part of A and add it to 100 parts of dimethylformamide, then add 1.2 parts of 5-aminofluorescein and 2 parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, Reaction at 20 ° C for 10 h to obtain product B. B was added to 100 parts of dichloromethane, and then 100 parts of water was added, and the mixture was evenly mixed and then left to stand for layers. Collect the organic phase, then add 200 parts of water, mix well, and then let stand for stratification. The organic phase was collected, added with 200 parts of water, mixed evenly, and then allowed to stand for layers. Take 1 part of C, add 8 parts of ethylene glycol monobutyl ether, mix well, and then add 50 parts of oxidized-sulfite fish oil anionic fatliquor together to obtain an anionic fluorescent labeling fatliquor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com