Converter gas mixing device and method

A converter gas and gas mixing technology, which is applied in the field of steel smelting, can solve the problems of affecting the roasting effect, reducing the CO content in the converter gas, and reducing the recovery rate, so as to reduce the construction cost and maintenance cost, improve the combustion rate and calorific value, The effect of meeting the needs of calcination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

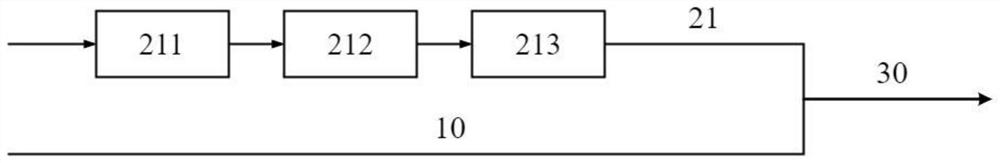

[0039] This embodiment provides a mixing device for converter gas, such as figure 1 As shown, the blending device includes a converter gas branch pipe 10, a propane gas pressure regulating unit, a propane gas branch pipe 21 and a mixed gas main pipe 30; the propane gas pressure regulating unit is connected to the propane gas branch pipe 21; the converter gas branch pipe 10 It is independently connected to the mixed gas main pipe 30 with the propane gas branch pipe 21 .

[0040] In this embodiment, the propane gas pressure regulating unit includes a compressor skid 211 , a hydrocarbon pump skid 212 and a gasification skid 213 connected in sequence, and the gasification skid 213 is connected to the propane gas branch pipe 21 . In addition, the converter gas branch pipe 10 and the propane gas branch pipe 21 are respectively independently provided with a gas velocity regulating valve ( figure 1 not marked).

Embodiment 2

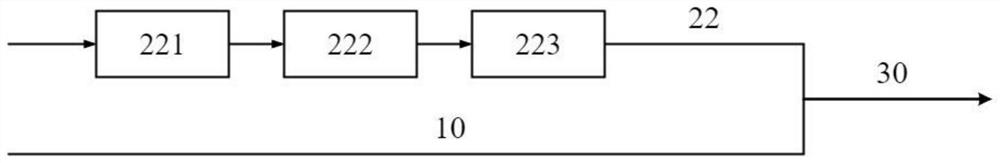

[0042] This embodiment provides a mixing device for converter gas, such as figure 2 As shown, the blending device includes a converter gas branch pipe 10, a natural gas pressure regulating unit, a natural gas branch pipe 22 and a mixed gas main pipe 30; the natural gas pressure regulating unit is connected to the natural gas branch pipe 22; the converter gas branch pipe 10 and the natural gas branch pipe 22 They are independently connected to the mixed gas main pipe 30 .

[0043] In this embodiment, the natural gas pressure regulating unit includes a vaporizer 221 , a reheater 222 and a diffuser 223 connected in sequence, and the diffuser 223 is connected to the natural gas branch pipe 22 . In addition, the converter gas branch pipe 10 and the natural gas branch pipe 22 are respectively independently provided with a gas velocity regulating valve ( figure 2 not marked).

Embodiment 3

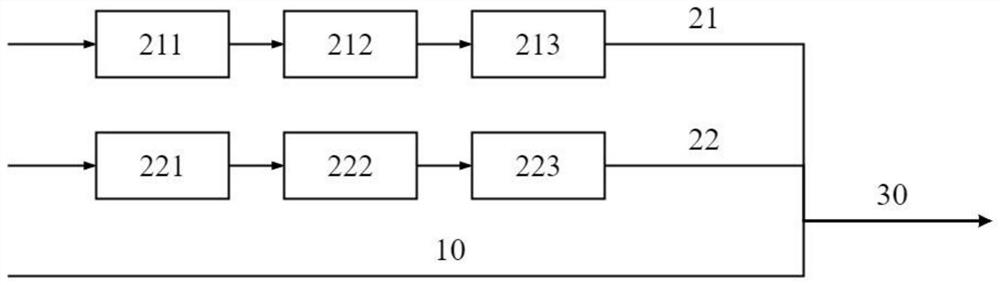

[0045] This embodiment provides a mixing device for converter gas, such as image 3 As shown, the blending device includes a converter gas branch pipe 10, a mixed gas pressure regulating unit, a mixed gas branch pipe and a mixed gas main pipe 30; the mixed gas pressure regulating unit includes a parallel propane gas pressure regulating unit and a natural gas pressure regulating unit The blended gas branch pipe includes parallel propane gas branch pipe 21 or natural gas branch pipe 22; the propane gas pressure regulating unit is connected with the propane gas branch pipe 21; the natural gas pressure regulating unit is connected with the natural gas branch pipe 22; the converter gas branch pipe 10. The propane gas branch pipe 21 and the natural gas branch pipe 22 are independently connected to the mixed gas main pipe 30 .

[0046] In this embodiment, the propane gas pressure regulating unit includes a compressor skid 211 , a hydrocarbon pump skid 212 and a gasification skid 213 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com