High-flux test reactor irradiation target and method for producing 252Cf by irradiating americium

A high-flux, test reactor technology, applied in the field of high-throughput test reactor irradiation targets and irradiated americium to produce 252Cf, can solve the problems of low production method efficiency, achieve reduced self-shielding effect, good irradiation effect, The effect of high engineering practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

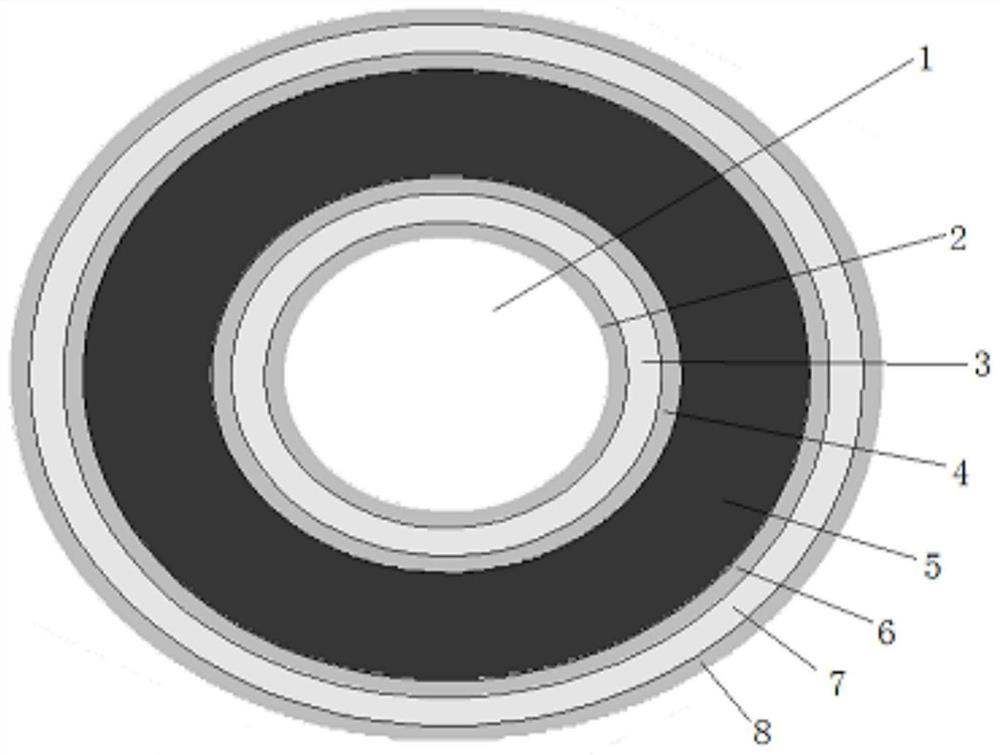

[0047] Such as figure 1 , figure 2 As shown, a high-throughput test reactor irradiation target of the present invention, the irradiation target is a kind of high-flux test reactor irradiation americium production 252 target of Cf;

[0048] The structure of the irradiation target adopts such as figure 1 As shown in the form of a ring-shaped rod bundle with a hollow channel, the irradiation target is sequentially composed of a tubular central channel 1, a first cladding layer 2, and a first cooling water gap layer from the inside to the outside along the radial direction of the target. 3. The second cladding layer 4, the matrix layer 5, the third cladding layer 6, the second cooling water gap layer 7 and the fourth cladding layer 8; the central channel 1 is water-through or sealed; the first cladding layer The materials of the shell layer 2 , the second shell layer 4 , the third shell layer 6 and the fourth shell layer 8 are all made of aluminum or zirconium. The material o...

Embodiment 2

[0059] Such as Figure 1 to Figure 4 As shown, the difference between this embodiment and embodiment 1 is that a high-throughput test reactor is used to irradiate americium to produce 252 The method of Cf, this method uses a kind of high-throughput test pile radiation target described in embodiment 1, such as Figure 4 As shown, the method includes the following steps:

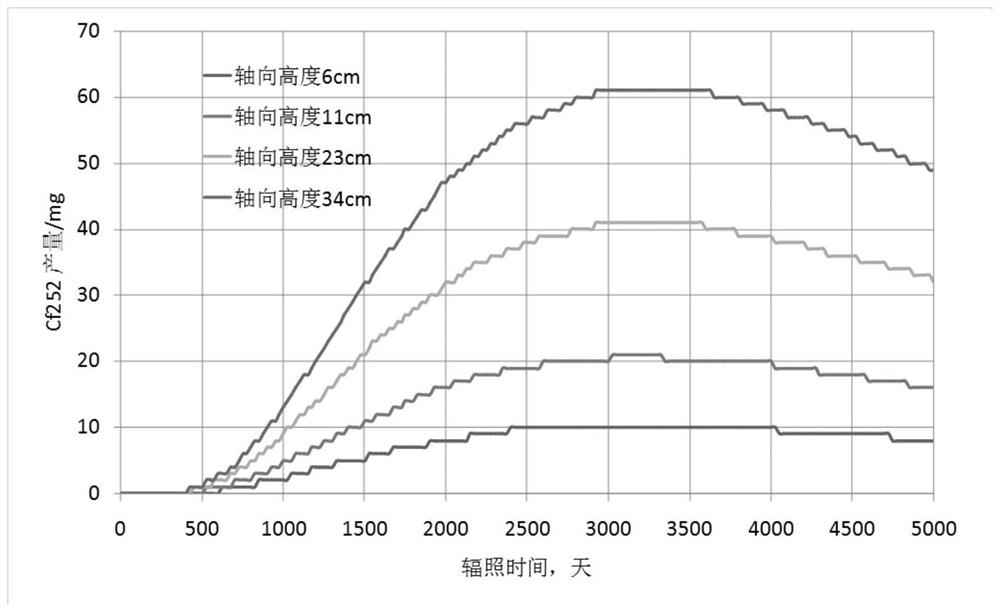

[0060] S1: During the shutdown of the irradiation reactor, select the height of the irradiation target of one of the high-flux test reactors, and install the irradiation target directly in the middle of the irradiation reactor where the flux is higher position; among them, the rational selection of the height of the target is to avoid the two ends of the target from entering the area with low neutron flux density;

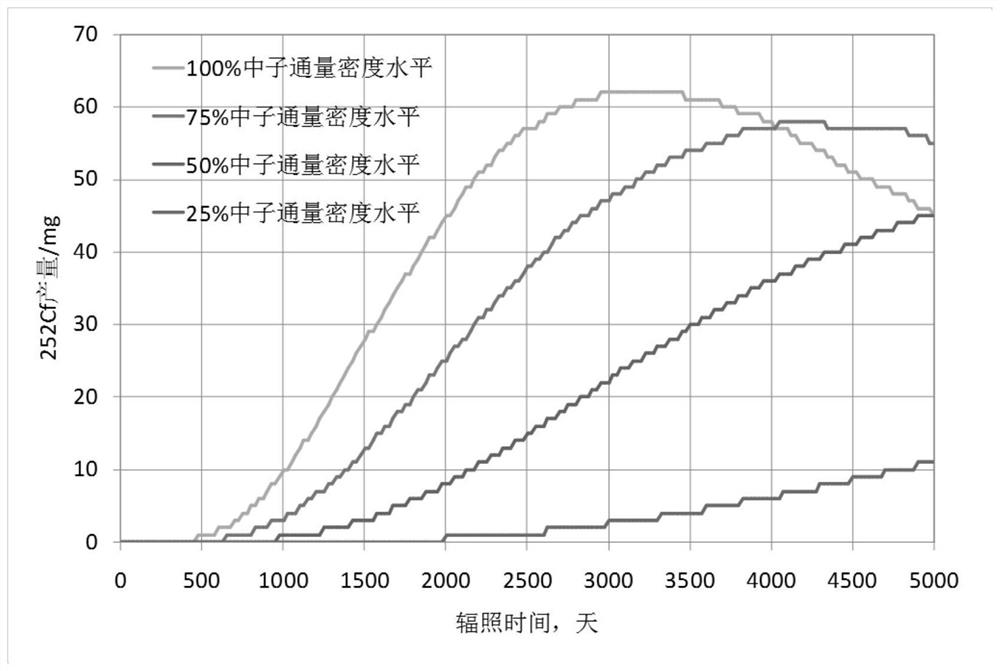

[0061] S2: adopt optimization measures to optimize the neutron energy spectrum at the installation position of the irradiation target, so that the neutrons are mainly distributed in the thermal g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com