Spherical aroma-enhanced tobacco particles and preparation method thereof

A tobacco particle and spherical technology, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, can solve the problems of insufficient fine particle strength, affecting the smoking experience, and high quantitative requirements, so as to improve the smoking feeling, reduce loss, and make up for the aroma. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

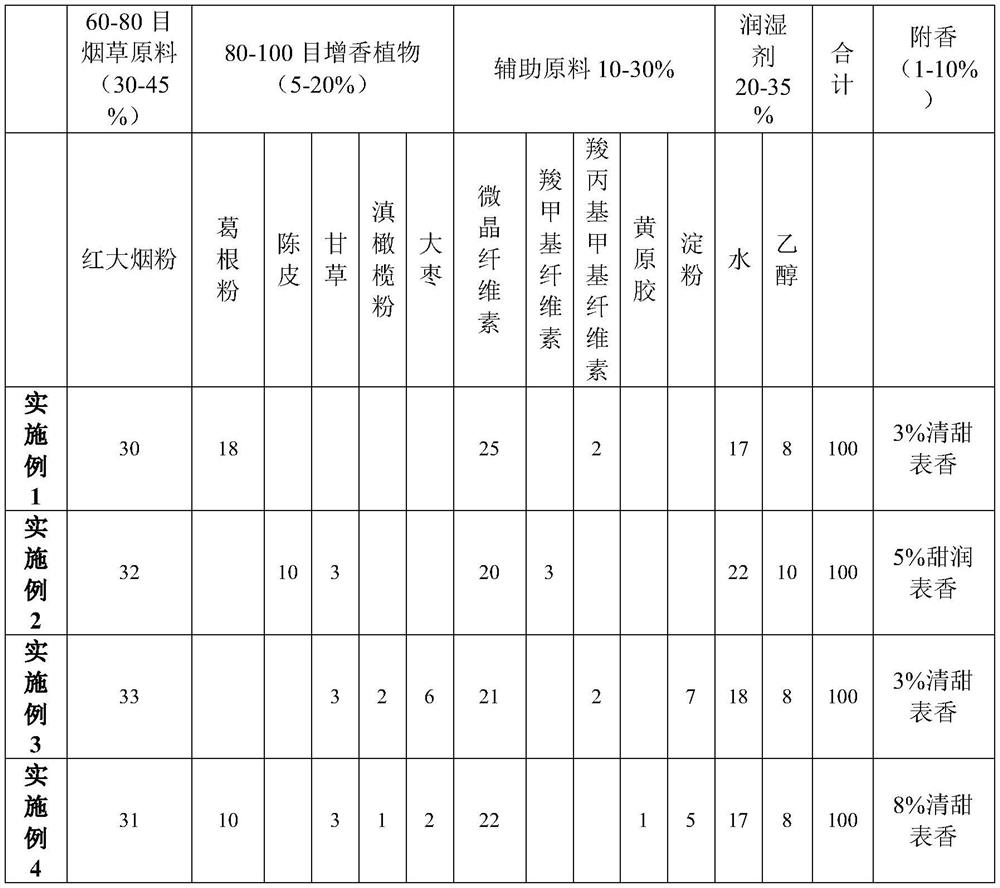

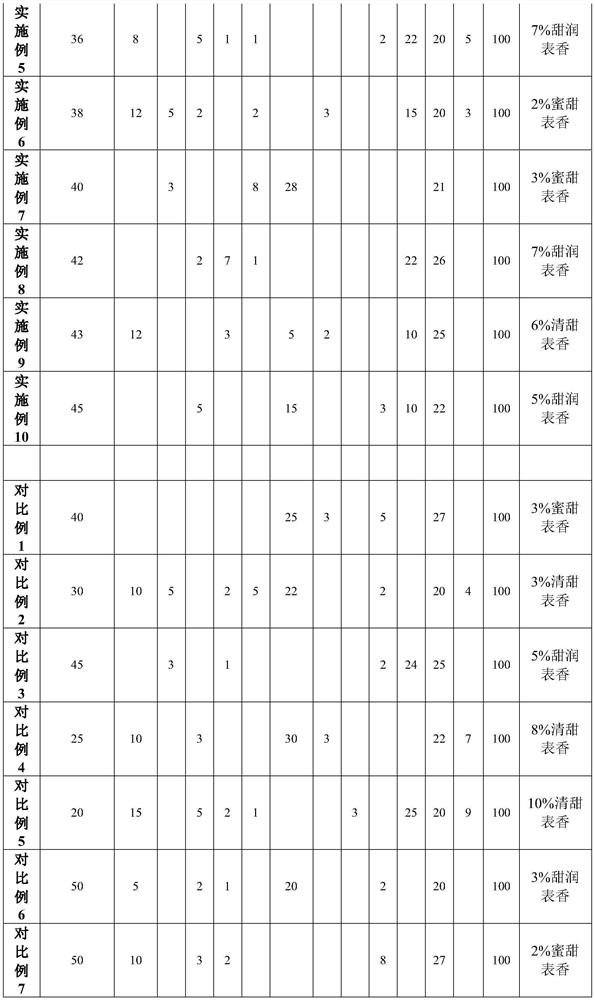

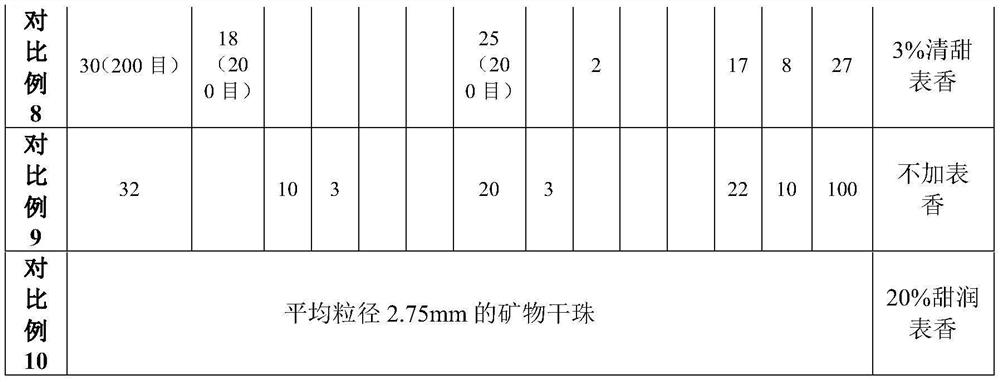

[0032] A preparation method of spherical flavored tobacco particles, the preparation method of the present invention comprises the following steps:

[0033] 1) Ingredients: 30-45% tobacco raw material, 5-20% flavoring plant powder, 10-30% auxiliary raw material, 20-35% wetting agent according to the mass percentage of raw material; the tobacco raw material is Yunnan Honghua Dajinyuan (Hongda) smoke powder, mesh number 60-80; the flavor-enhancing plant powder is one or more of kudzu root, tangerine peel, licorice, Yunnan olive, and jujube, mesh number 80-100 Purpose; the auxiliary raw material is one or more of microcrystalline cellulose, carboxymethyl cellulose, carboxypropyl methyl cellulose, xanthan gum, and starch; the wetting agent is water, ethanol 1. One or more of water-ethanol mixtures; the mesh size of the microcrystalline cellulose is 120-150 mesh;

[0034] 2) Stirring: Pre-stir the weighed material first, then add wetting agent and stir evenly;

[0035] 3) Molding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com