POSS/PVDF composite membrane with hydrophobic surface, preparation method and application thereof

A hydrophobic surface and composite membrane technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as high technical cost, difficulty in large-scale industrial application, and complicated steps. Achieve the effect of simple process, promotion of industrial application and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

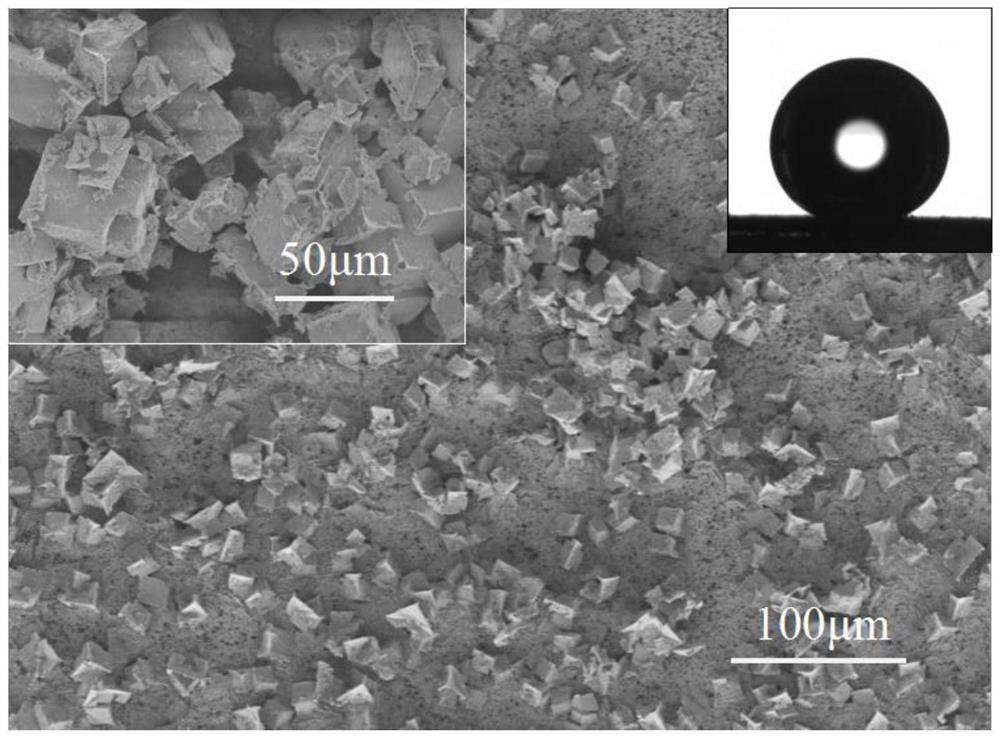

[0045] According to an embodiment of the present disclosure, a method for preparing a POSS / PVDF composite membrane with a hydrophobic surface is provided, comprising:

[0046] Alkali treatment is carried out on the polyvinylidene fluoride film by using lye to obtain the alkali-treated polyvinylidene fluoride film;

[0047] Dissolving 3-mercaptopropyltriethoxysilane in ethanol to obtain a modified solution; then, using the modified solution to modify the polyvinylidene fluoride film with alkali to obtain a modified polyvinylidene fluoride film;

[0048] Dissolving octavinyl cage silsesquioxane in dichloromethane to obtain a solution, and then adding 2-hydroxy-2-methylpropiophenone to the solution to obtain a sol;

[0049] The modified polyvinylidene fluoride film was immersed in the sol, and irradiated with ultraviolet light to obtain the POSS / PVDF composite film.

[0050] The preparation method provided by the present disclosure triggers a click reaction through ultraviolet l...

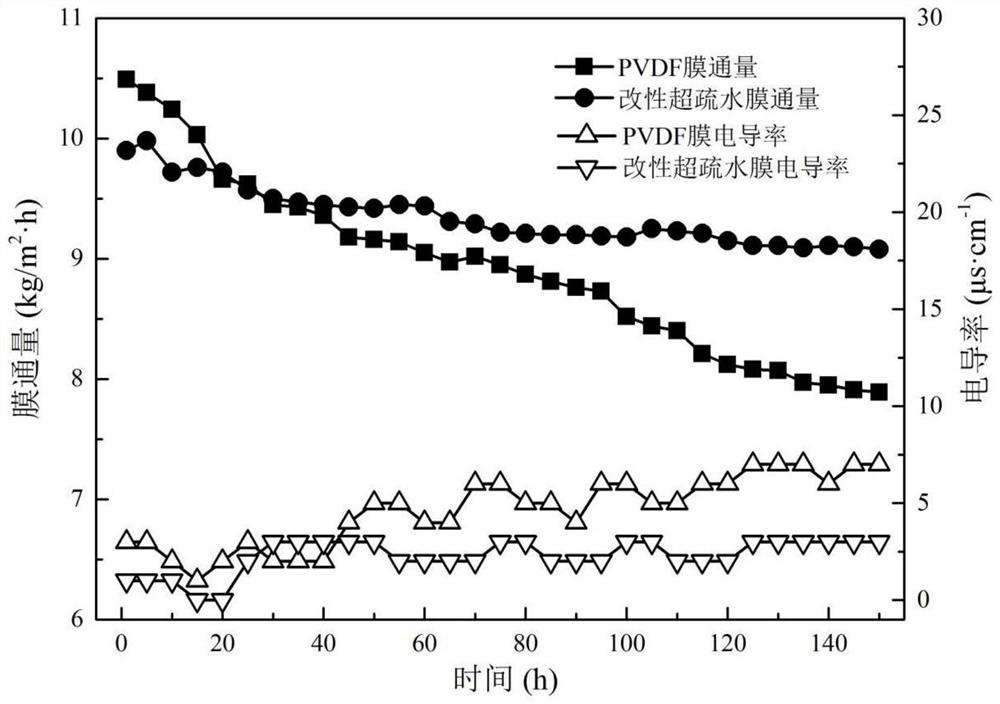

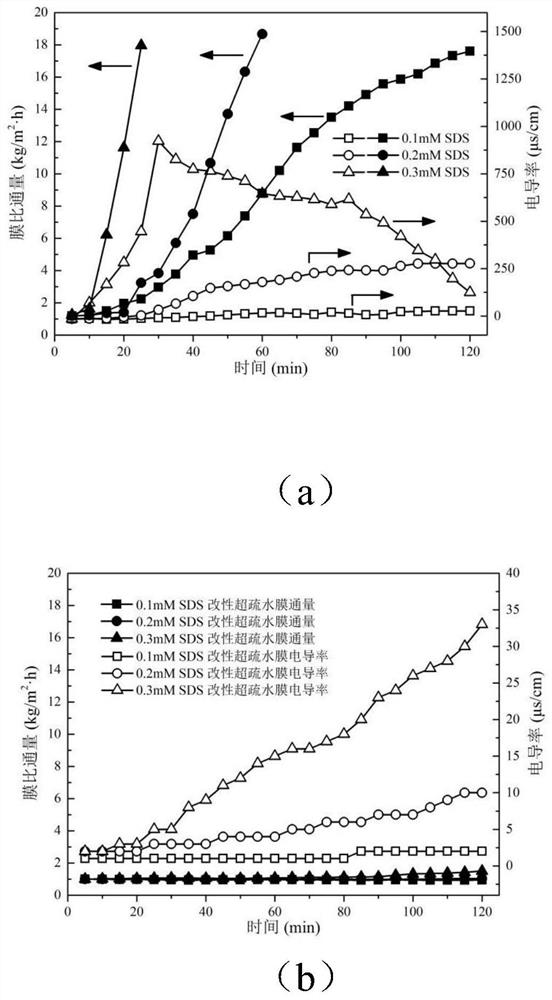

Embodiment 1

[0073] A method for preparing a POSS / PVDF composite membrane with a hydrophobic surface, comprising,

[0074] (1) Preparation of alkali-treated PVDF membrane: immerse the PVDF membrane in 2mol L -1 NaOH solution, and treated at 20°C for 2 hours, to introduce hydroxyl groups on the surface of the PVDF membrane, and obtain an alkali-treated PVDF membrane.

[0075] (2) Preparation of modified PVDF membrane: Dissolve MPTES in ethanol and stir to obtain a modified solution with a concentration of 0.1mol L -1 Then, at 20°C, immerse the alkali-treated PVDF membrane in step (1) in the modification solution, take it out after soaking for 2h, and rinse it with ethanol, and dry it at 60°C for 2h to obtain the modified polyvinylidene fluoride membrane.

[0076] (3) Preparation of sol: Add OVPOSS to DMC, stir magnetically at a speed of 100r / min for 2h, and then ultrasonically disperse at 20°C for 2h to fully dissolve OVPOSS in DMC to obtain OVPOSS / DMC with a mass fraction of 1%. solutio...

Embodiment 2

[0096] A method for preparing a POSS / PVDF composite membrane with a hydrophobic surface, comprising,

[0097] (1) Preparation of alkali-treated PVDF membrane: immerse the PVDF membrane in 3mol L -1 NaOH solution, and treated at 30°C for 4 hours, to introduce hydroxyl groups on the surface of the PVDF membrane to obtain an alkali-treated PVDF membrane.

[0098] (2) Preparation of modified PVDF membrane: Dissolve MPTES in ethanol and stir to obtain a modified solution with a concentration of 0.2mol L -l Then, at 30°C, immerse the alkali-treated PVDF membrane in step (1) in the modification solution, take it out after soaking for 4h, and rinse it with ethanol, and dry it at 70°C for 4h to obtain the modified polyvinylidene fluoride membrane.

[0099] (3) Preparation of sol: Add OVPOSS into DMC, stir magnetically at 200r / min for 4h, then ultrasonically disperse at 25°C for 4h, so that OVPOSS is fully dissolved in DMC to obtain OVPOSS / DMC with a mass fraction of 2%. solution; afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com