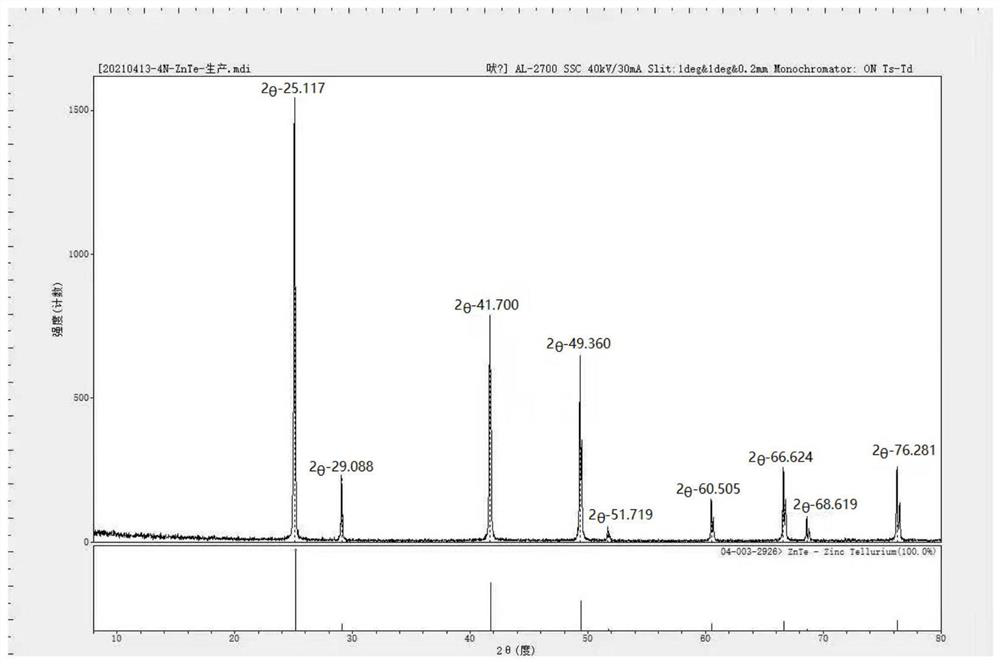

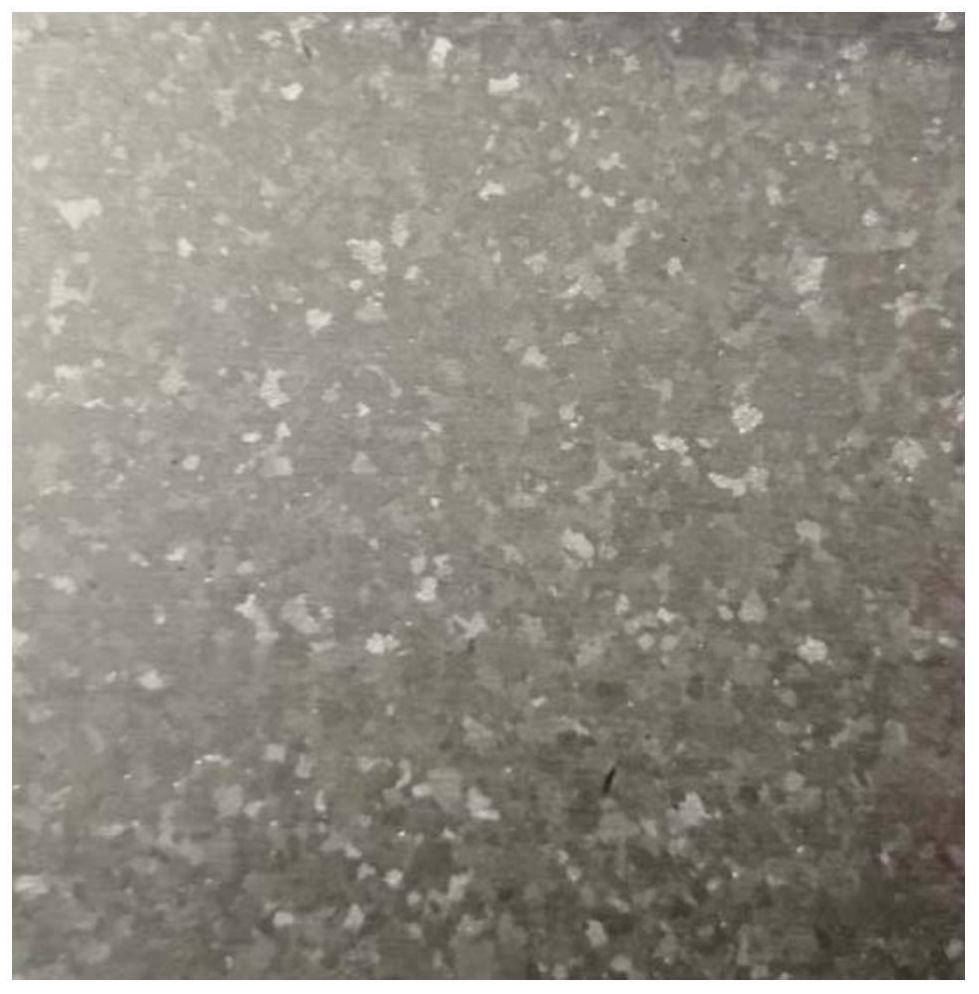

Polycrystal single-phase zinc telluride and preparation method thereof

A zinc telluride, polycrystalline technology, applied in binary selenium/tellurium compounds, metal selenide/tellurium compounds, etc., can solve the problems of high cost, high cost, difficulty in obtaining a single-phase structure, etc. The effect of short molding time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of polycrystalline single-phase zinc telluride, comprising the following steps:

[0042] (1) Prepare a clean quartz crucible and quartz tube, mix high-purity metal zinc particles with a purity of more than 99.995% and 99.999% tellurium particles in an atomic ratio of 1:1 and put them into the quartz crucible, zinc particles and tellurium particles The particle size of the crucible is about 3mm, and the height of the particles in the crucible is not higher than 1 / 2 of the height of the crucible. Cover the crucible with a quartz cover, put the crucible into a quartz tube, use the quartz tube as a sealed reaction kettle, and place it put into the tube sintering furnace;

[0043] (2) Vacuum the quartz tube to 1x10 -5 Below Pa, at the same time, raise the furnace temperature to 350°C to preheat the material. The preheating time is 60 minutes. The purpose is to dry the moisture carried in the raw material and the volatile substances remaining on the surf...

Embodiment 2

[0059] A preparation method of polycrystalline single-phase zinc telluride, comprising the following steps:

[0060] (1) Prepare a clean quartz crucible and quartz tube, mix high-purity metal copper particles, zinc particles and tellurium particles with a purity of more than 99.995% in an atomic ratio of 1:49.5:49.5 and put them into the quartz crucible. The particle diameters of zinc particles and tellurium particles are between 2.0mm-4.0mm, and the height of the particles in the crucible is not higher than 1 / 2 of the height of the crucible. Cover the crucible with a quartz cover and put the crucible into the quartz tube. Use the quartz tube as a sealed reaction kettle and put it into the tube sintering furnace;

[0061] (2) Vacuum the quartz tube to 1×10 -5 Below Pa, at the same time, raise the furnace temperature to 250°C to preheat the material. The preheating time is 65 minutes. The purpose is to dry the moisture carried in the raw material and the volatile substances re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com