A multi-source solid waste composite high-fluid backfill material and its preparation method and application

A high-fluidity, high-efficiency technology, applied in the field of civil engineering materials, can solve the problems of difficult construction of foundation trenches with special-shaped facets, low utilization rate of spoil, and non-compact backfilling, etc. It achieves good strength and durability and requires less manpower , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

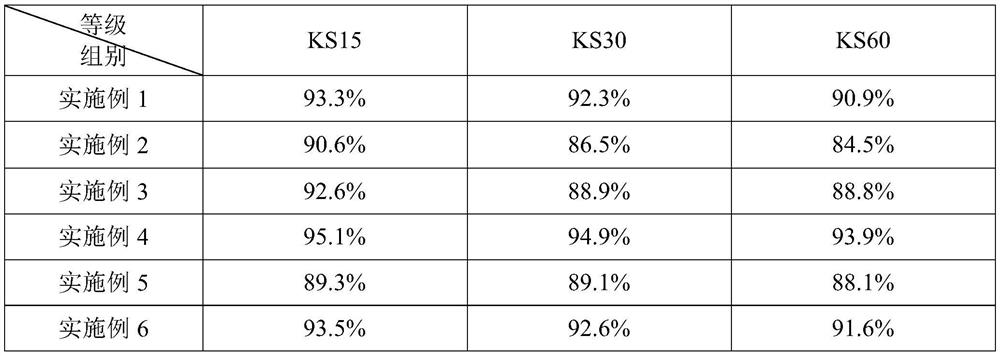

Examples

Embodiment 1

[0031] A multi-source solid waste composite high-fluidity backfill material is provided. According to parts by weight, the components are 1000 parts of muck, 55 parts of cement, 15 parts of ultrafine slag powder, 15 parts of fly ash, and 20 parts of phosphogypsum. 12 parts of high-efficiency curing agent, 300 parts of water. Wherein the high-efficiency curing agent is in parts by weight, and the components are 60 parts of sulfonated formaldehyde-acetone condensation polymers, 24 parts of water glass, 12 parts of sodium lauryl sulfate, and 15 parts of water-soluble epoxy resin; the water glass and The water-soluble epoxy resin is calculated in parts by weight of effective components.

[0032] The technical index of raw material used in the present embodiment is:

[0033] The maximum particle size of the slag is 15.8cm, and the organic matter content in the slag is 3.24wt%.

[0034] The cement is PO42.5 ordinary Portland cement.

[0035] The bulk density of superfine slag powde...

Embodiment 2

[0042] A multi-source solid waste composite high-fluidity backfill material is provided. According to parts by weight, the components are 1020 parts of muck, 55 parts of cement, 15 parts of ultrafine slag powder, 20 parts of fly ash, and 20 parts of phosphogypsum. 11 parts of high-efficiency curing agent, 350 parts of water. Among them, the high-efficiency curing agent is calculated in parts by weight, and the components are 50 parts of sulfonated formaldehyde-acetone polycondensate, 20 parts of water glass, 12 parts of sodium lauryl sulfate, 15 parts of water-soluble epoxy resin, and 5 parts of sulfonated oil , 5 parts of sodium sulfate; Described water glass and water-soluble epoxy resin are calculated by weight parts of effective components.

[0043] The technical index of raw material used in the present embodiment is:

[0044] The maximum particle size of the slag is 19.8cm, and the organic matter content in the slag is 2.34wt%.

[0045] The cement is PO42.5 ordinary Po...

Embodiment 3

[0054] A multi-source solid waste composite high-fluid backfill material is provided. According to parts by weight, the components are 950 parts of muck, 40 parts of cement, 20 parts of ultrafine slag powder, 20 parts of fly ash, and 20 parts of phosphogypsum. High-efficiency curing agent 15 parts, water 275 parts. Among them, the high-efficiency curing agent is calculated in parts by weight, and the components are 50 parts of sulfonated formaldehyde-acetone polycondensate, 24 parts of water glass, 12 parts of sodium lauryl sulfate, 15 parts of water-soluble epoxy resin, and 5 parts of sulfonated oil ; The water glass and water-soluble epoxy resin are calculated in parts by weight of effective components.

[0055] The technical index of raw material used in this embodiment is:

[0056] The maximum particle size of the slag is 13.8cm, and the organic matter content in the slag is 3.26wt%.

[0057] The cement is PO52.5 ordinary Portland cement.

[0058] Ultrafine slag powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com