Colored curable resin composition

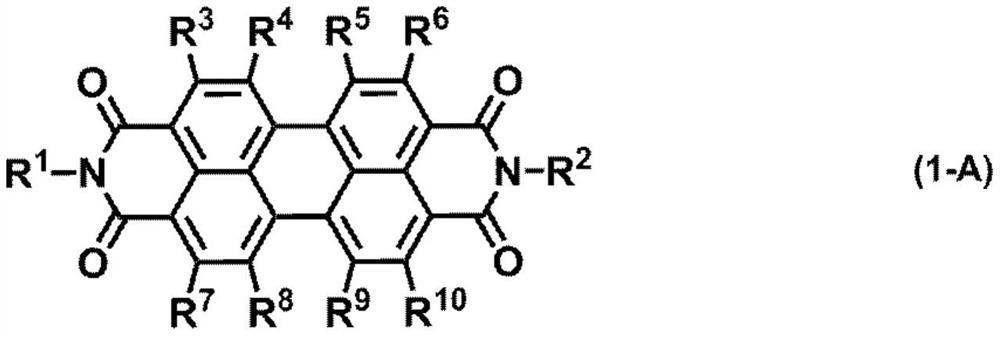

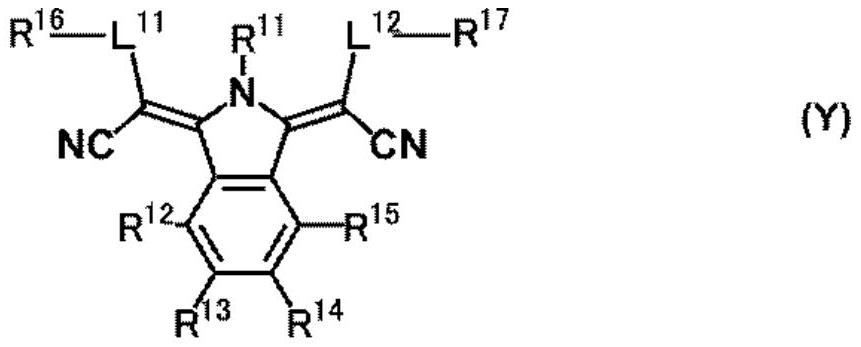

A technology of curable resin and composition, applied in perylene derivatives, chemical instruments and methods, anthracene dyes, etc., can solve the problem of unoptimized thick film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0155] Hereinafter, the present invention will be described in more detail with reference to examples, but the present invention is not limited by the following examples. In the examples, unless otherwise specified, "part" means "part by mass", and "%" means "% by mass".

[0156] In the following synthesis examples, compounds were identified by mass spectrometry (LC; Agilent 1200, MASS; Agilent LC / MSD) or elemental analysis (VARIO-EL; Elementar).

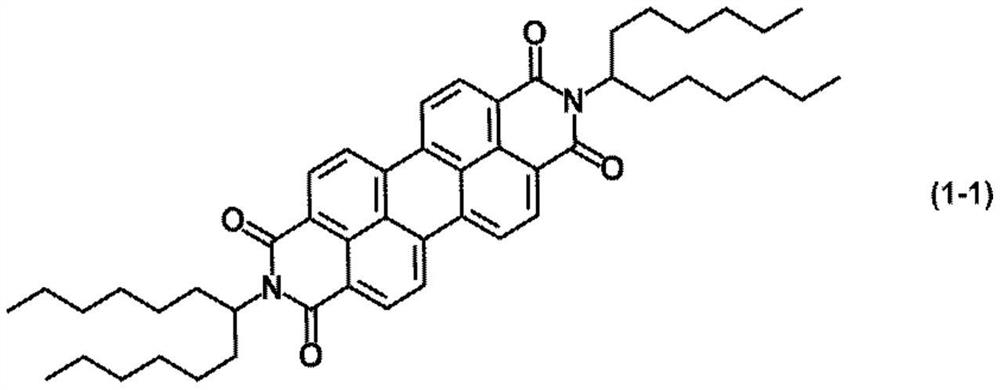

Synthetic example 1

[0158] Add 8.0 parts of 3,4,9,10-perylenetetracarboxylic dianhydride (manufactured by Tokyo Chemical Industry Co., Ltd.), 10 parts of 7-aminotridecane (manufactured by Tokyo Chemical Industry Co., Ltd.), and 1.3 parts of zinc acetate (manufactured by Kanto Chemical Industry Co., Ltd.) Co., Ltd.) and 314 parts of imidazole (Tokyo Chemical Industry Co., Ltd.) were stirred at 150° C. for 3 hours. While keeping the obtained mixture at 20° C. or lower, 267 parts of 37% hydrochloric acid (manufactured by Kanto Chemical Co., Ltd.) prepared beforehand and 1300 parts of water were added to produce an orange-red precipitate. The mixture containing the orange-red precipitate was filtered, and the filtered residue was washed with 400 parts of water and 200 parts of methanol. The obtained residue was dried under reduced pressure at 60° C. to obtain 12 parts of a compound represented by formula (1-1) (hereinafter also referred to as compound (1-1)) (79% yield).

[0159]

[0160]

[01...

Synthetic example 2

[0164] 8.0 parts of 3,4,9,10-perylenetetracarboxylic dianhydride (manufactured by Tokyo Chemical Industry Co., Ltd.), 3.8 parts of glycine (manufactured by Tokyo Chemical Industry Co., Ltd.), 1.3 parts of zinc acetate (manufactured by Kanto Chemical Industry Co., Ltd.) and 314 parts of imidazoles (manufactured by Tokyo Chemical Industry Co., Ltd.) were stirred at 150° C. for 7 hours. While keeping the obtained mixture at 20° C. or lower, 267 parts of 37% hydrochloric acid (manufactured by Kanto Chemical Co., Ltd.) prepared beforehand and 1300 parts of water were added to produce an orange-red precipitate. The mixture containing the orange-red precipitate was filtered, and the filtered residue was washed with 400 parts of water and 200 parts of methanol. The obtained residue was dried under reduced pressure at 60° C. to obtain 9.1 parts of a compound represented by formula (1-2) (also referred to as compound (1-2)) (88% yield).

[0165]

[0166]

[0167] (Mass spectrometr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com