Carriage side leakage preventing device for self-dumping semitrailer and using method of carriage side leakage preventing device

A semi-trailer, anti-side leakage technology, applied in packaging, motor vehicles, vehicle parts and other directions to achieve the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

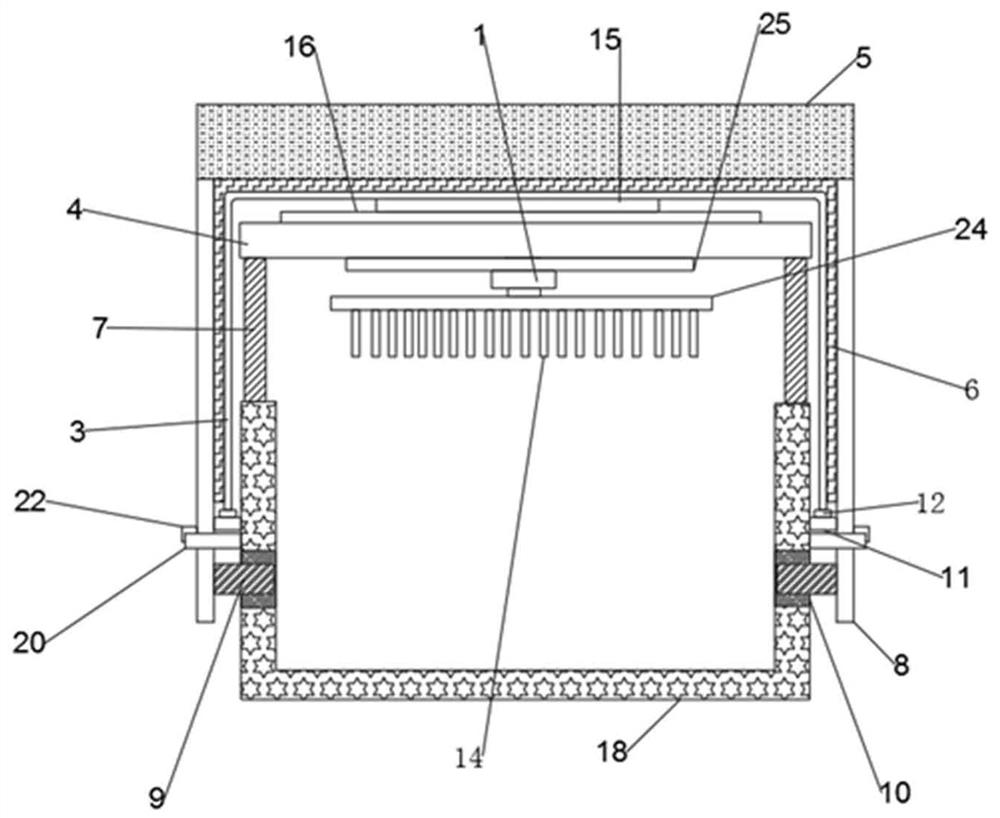

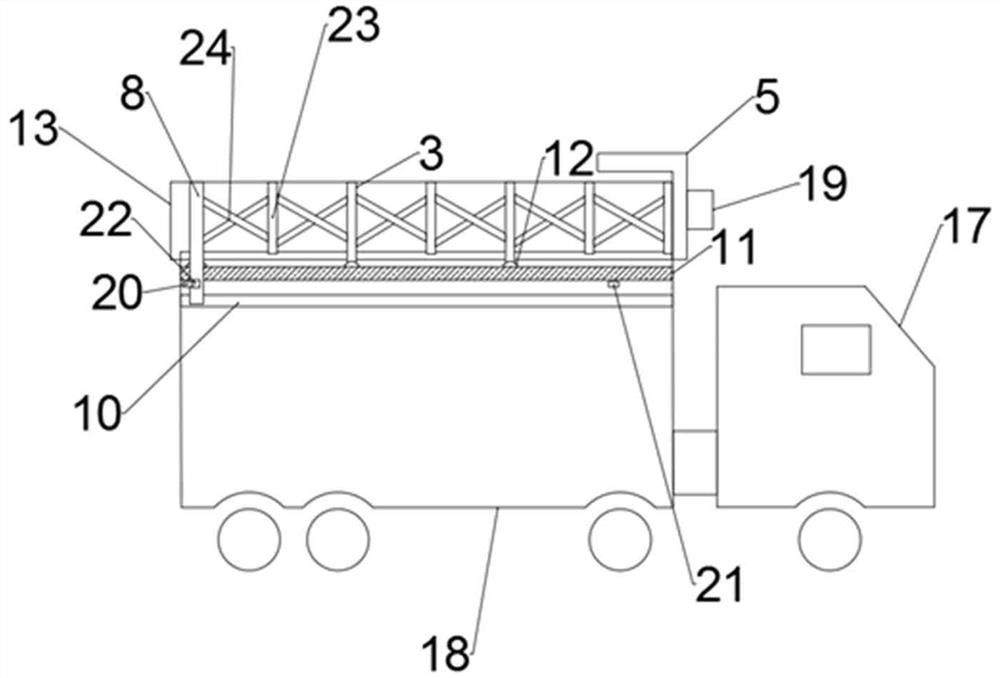

[0028] A compartment side leakage prevention device for a self-unloading semi-trailer, comprising a front 17 and a compartment 18, the top of the compartment 18 is provided with an automatic retractable awning 13, and the outer side of the automatic telescopic awning 13 is fixedly connected with a vertical rod 8. A first limit switch 20 is fixedly connected to the top of the two sides of the compartment 18 near the rear of the compartment 18, and the inner side of the first limit switch 20 is fixedly connected to a second limit switch 21 at the front end of the compartment 18. 18, a support rod 7 is fixedly connected to the upper left side, and a baffle plate 4 is fixedly connected to the top of the support rod 7. A fixed block 16 is arranged on the inside of the compartment 18, and the bottom of the fixed block 16 is fixed by a connecting plate 25. An electric telescopic rod 1 is connected.

[0029] In this implementation, a sun visor 5 is fixedly connected to the upper right...

Embodiment 2

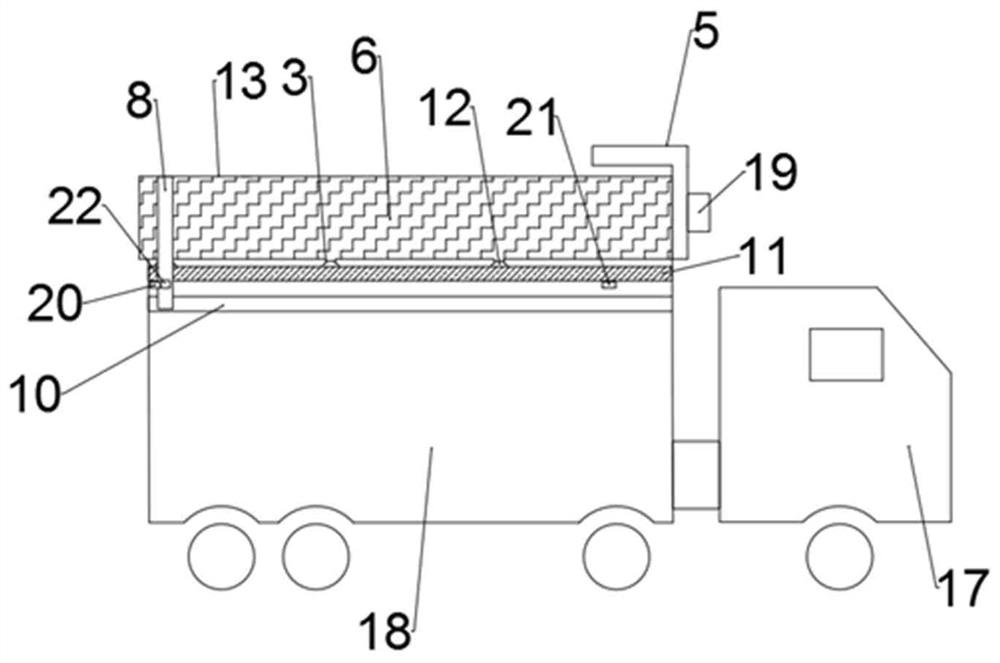

[0035] When the fixed block 16 moved to the left, the bottom end of the fixed block 16 was driven by the electric telescopic rod 1 fixedly connected with the connecting plate 25 to drive the bottom plate 24 and the stainless steel rake 14 to move down to the raised position of the sand and soil, and began to remove the sand and soil. Carry out flattening processing, make the height of sand and soil be lower than the height of compartment 18, when the limit block 22 on the vertical rod 8 contacts with the first limit switch, drive motor 19 stops working, and electric telescopic rod 1 drives base plate 24 and stainless steel The whole body consisting of rakes 14 moves upward together to the compressed state, at this time the automatic retractable canopy 13 is in a stretched state, protecting the sand and soil in the compartment 18 from being wet by rain during transportation, and preventing side leakage of the sand and soil during the bumping process pollute the environment.

[...

Embodiment 3

[0043] When needing unloading, turn on the control switch in the headstock 17, and now the drive motor 19 starts to work, and the drive motor 19 drives the fixed block 16 to move to the right under the action of the threaded rod 2 and the slide bar 26, and the fixed block 16 drives the automatic expansion and contraction simultaneously. The vertical rod 8 outside the tent 13 moves to the right, and slides to the front end of the compartment 18 under the action of the slider 9 and the chute 10 at the bottom of the vertical rod 8. When the limit block 22 on the vertical rod 8 touches the first During the second limit switch 21, the control switch in the headstock 17 was closed, and the drive motor 19 stopped working. At this time, the automatic telescopic tent 13 was in a compressed state, and was positioned under the sun visor 5, which played a role in sun protection and prevented the automatic telescopic tent 13 from growing. Damaged over time by exposure to sunlight.

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com