Device and method for recovering unpolymerized chlorotrifluoroethylene monomer

A polychlorotrifluoroethylene and trifluorochloroethylene technology, which is applied in chemical instruments and methods, halogenated hydrocarbon disproportionation separation/purification, organic chemistry, etc., to achieve the effects of simple equipment, easy implementation and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

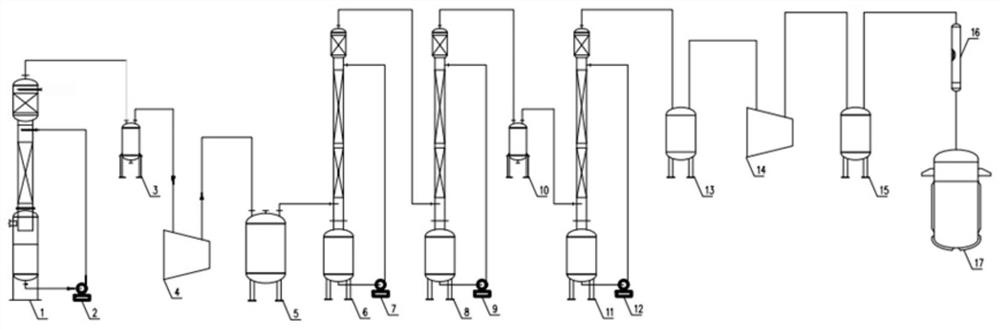

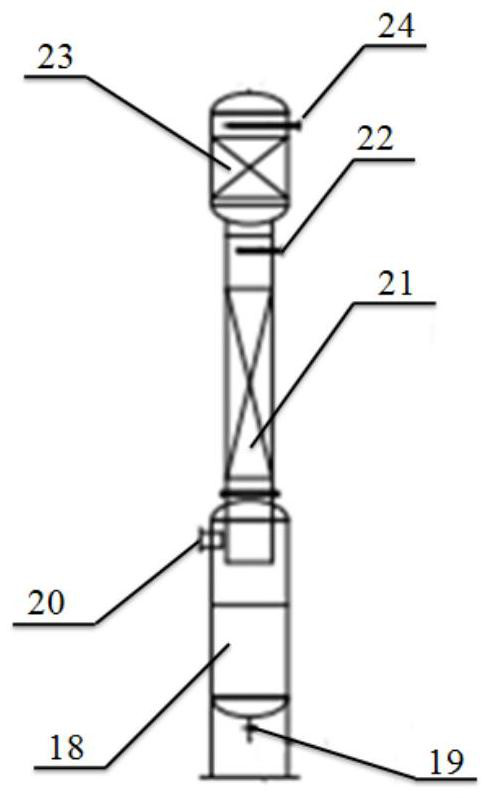

[0033] (1) During the production of polytrifluorochloroethylene by the suspension method, the unpolymerized chlorotrifluoroethylene monomer in the polymerization reactor enters through the air inlet 19 of the cyclone-like separator structure in the polytrifluoroethylene dust scrubber 1 In the polychlorotrifluoroethylene dust washing tower 1, most of the polychlorotrifluoroethylene dust particles entrained by the unpolymerized chlorotrifluoroethylene monomer spiral down to the tower kettle 18 at this position, and float on the upper part of the liquid, with a small amount of unsettled The polytrifluorochloroethylene particles that come down are washed by water (including the pure water entered by the 22 water inlet and the distribution device and the circulating water circulated by the polytrifluorochloroethylene circulating water pump 2) in the plate type washing tower 21, and then passed through the plate type washing tower 21 The upper wire mesh eliminator 23 further intercep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com