A polyurethane-based shape memory polymer, polymer electrolyte and its preparation

A memory polymer, polyurethane prepolymer technology, used in circuits, electrical components, secondary batteries, etc., can solve the problems of inconvenience to meet practical application needs, low conversion temperature, etc., to improve application convenience, improve mechanical properties, Effect of Wide Transition Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

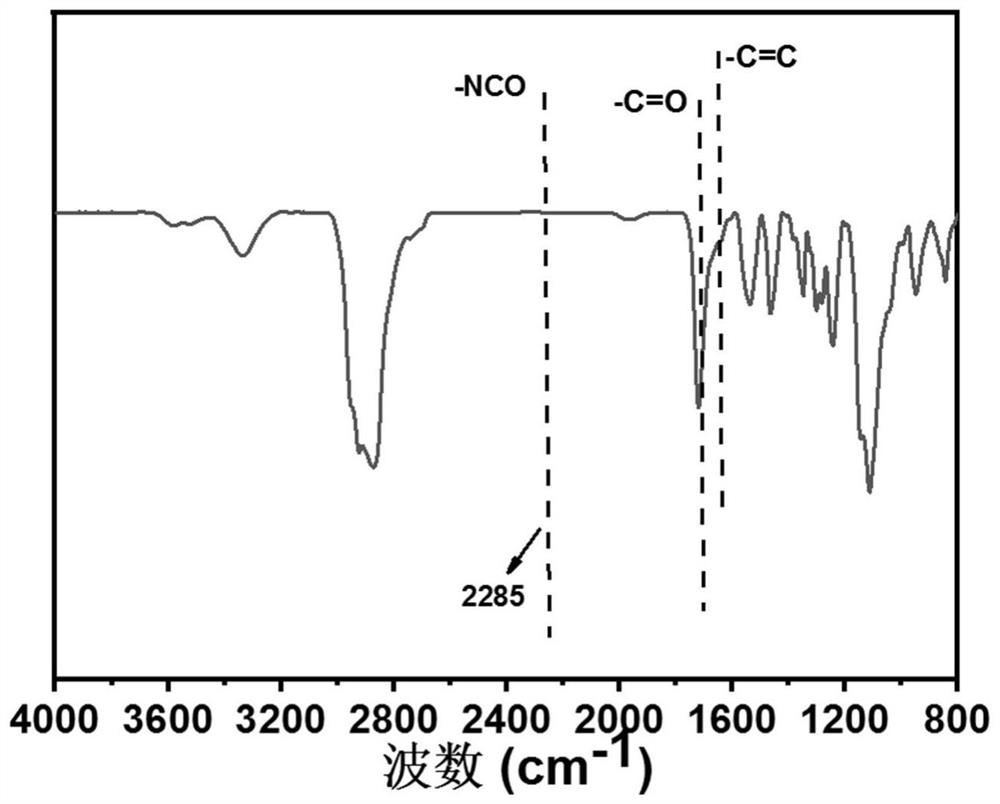

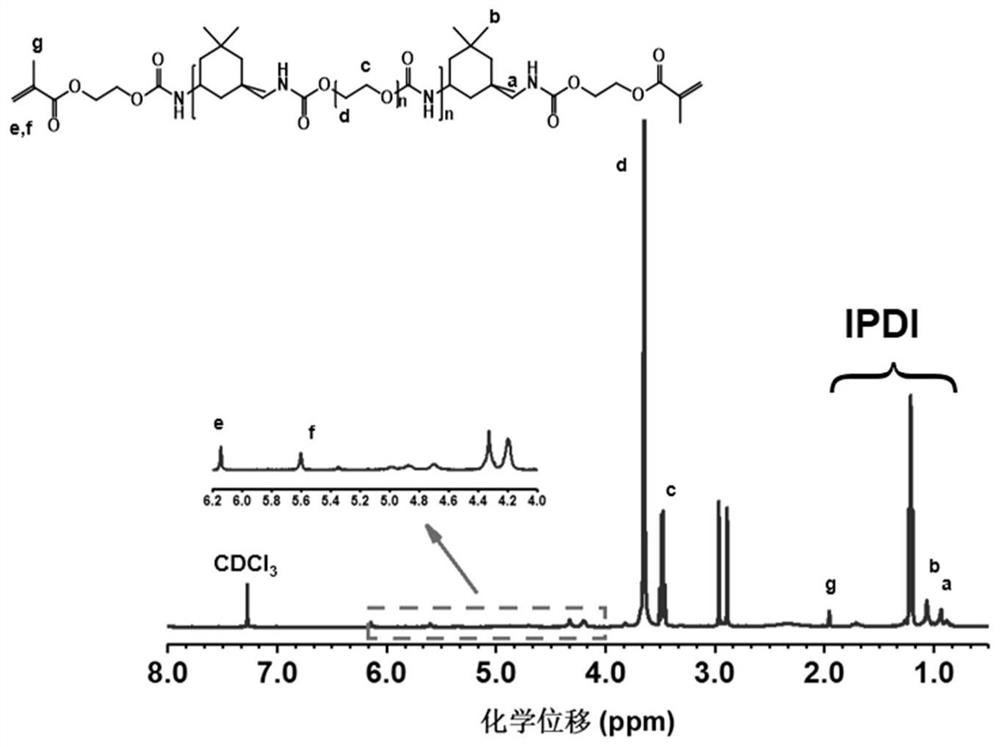

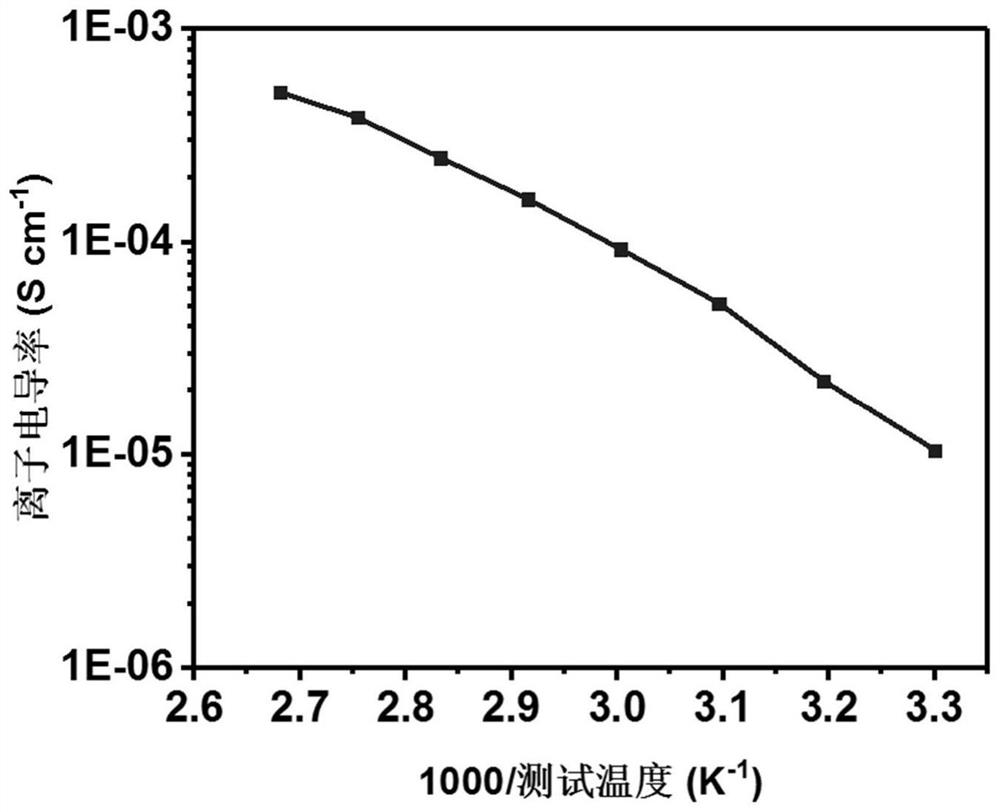

[0058] In this embodiment, a polyurethane-based shape memory polymer electrolyte includes a polyurethane crosslinking agent, an acrylate crosslinking agent containing a disulfide bond, and a polyethylene glycol acrylate monomer, and the diisocyanate compound and polyethylene The diol molar ratio is 2:1, the molar ratio of the polyurethane prepolymer synthesized by the polycondensation of the diisocyanate compound and polyethylene glycol to hydroxyethyl methacrylate is 2:1, and the acrylic isocyanate and disulfide bond The compound molar ratio is 2:1, the diisocyanate compound is isophorone diisocyanate, the acrylic isocyanate is isocyanoethyl methacrylate, the disulfide bond compound is cystamine, and the polyethylene The molecular weight of diol is 2000, and the molecular weight of described polyethylene glycol methyl ether methacrylate is 2070, and described polyethylene glycol methyl ether methacrylate and the acrylate crosslinking agent containing disulfide bond and polyure...

Embodiment 2

[0072] In this embodiment, a polyurethane-based shape memory polymer electrolyte includes a polyurethane crosslinking agent, an acrylate crosslinking agent containing a disulfide bond, and a polyethylene glycol acrylate monomer, and the diisocyanate compound and polyethylene The diol molar ratio is 3:1, the molar ratio of the polyurethane prepolymer synthesized by the polycondensation of the diisocyanate compound and polyethylene glycol to hydroxyethyl methacrylate is 3:1, and the acrylic isocyanate and disulfide bond The compound molar ratio is 1:1, the diisocyanate compound is hexamethylene diisocyanate, the acrylic isocyanate is isocyanoethyl acrylate, the disulfide bond compound is cystamine, and the polyethylene glycol The molecular weight of the polyethylene glycol methyl ether methacrylate is 1000, and the molecular weight of the polyethylene glycol methyl ether methacrylate is 1070, and the polyethylene glycol methyl ether methacrylate and the acrylate crosslinking agen...

Embodiment 3

[0077] In this embodiment, a polyurethane-based shape memory polymer electrolyte includes a polyurethane crosslinking agent, an acrylate crosslinking agent containing a disulfide bond, and a polyethylene glycol acrylate monomer, and the diisocyanate compound and polyethylene The diol molar ratio is 4:1, and the molar ratio of the polyurethane prepolymer synthesized by polycondensation of the diisocyanate compound and polyethylene glycol to hydroxyethyl methacrylate is 4:1, and the acrylic isocyanate and disulfide bond The compound molar ratio is 1:2, the diisocyanate compound is 4,4'-methylene bis(phenylisocyanate), the acrylic isocyanate is isocyanoethyl acrylate, and the disulfide bond compound is 4,4'-diaminodiphenyl disulfide, the polyethylene glycol has a molecular weight of 600, the polyethylene glycol methyl ether methacrylate has a molecular weight of 670, and the polyethylene glycol methyl ether methyl The molar ratio of acrylate-based acrylate to disulfide bond-conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com