Preparation method and application of titanium phosphorus catalyst for polyester synthesis

A catalyst and polyester technology, applied in the production of bulk chemicals, etc., can solve the problems of unsatisfactory hue and various indicators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

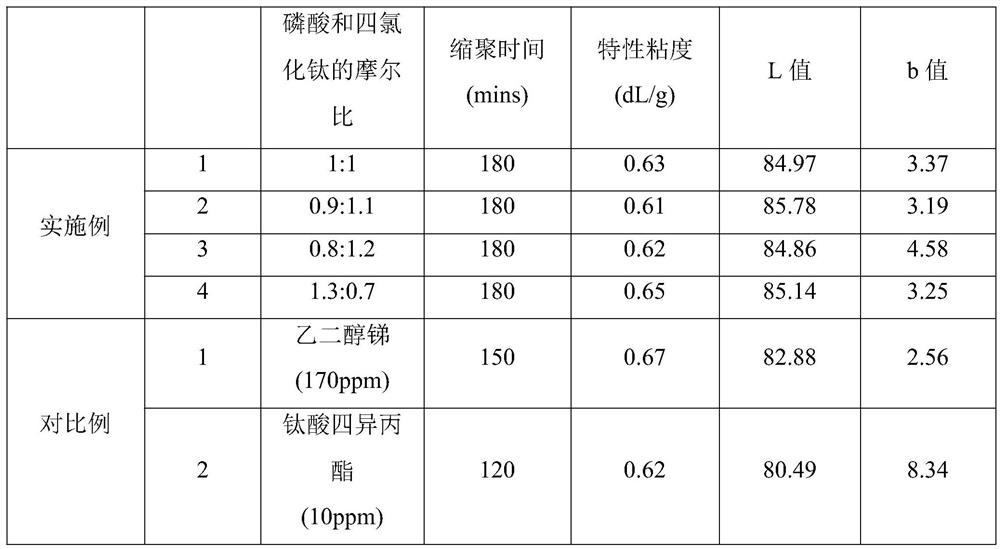

Examples

preparation example Construction

[0028] Catalyst preparation:

[0029] Dissolve fatty alkyltrimethylammonium halide in deionized water, stir vigorously until a uniform and stable solution is formed; and dissolve titanium compound and phosphorus compound in the above mixed solution at a molar ratio (1:9~9:1) , continuously stirred and reacted at 20-200°C for 1.0-72.0h; filtered the obtained mixed solution, and roasted the solid at 300-800°C for 0.5-8.0h, then washed the roasted product repeatedly with water, dried in vacuum at room temperature, After crushing and grinding, the titanium phosphorus catalyst is obtained.

[0030] Wherein, the titanium compound is at least one of titanium tetrachloride, titanium tetrabromide and titanate compounds. Wherein, the titanate compound has the general formula of Ti(OR)4, and R is an alkyl group with 1-10 carbon atoms.

[0031] The phosphorus compound is at least one of phosphoric acid, polyphosphoric acid, phosphorus pentoxide, phosphorus trichloride and pyrophosphoric...

Embodiment 1

[0037] Catalyst preparation:

[0038] Dissolve 16.5g of octadecyltrimethylammonium bromide in 150ml of deionized water, stir vigorously until a uniform and stable solution is formed; then add phosphoric acid and titanium tetrachloride to the above mixed solution at a molar ratio of 1:1, first Add 9.8 g (0.10 mol) of phosphoric acid, and add 18.9 g (0.10 mol) of titanium tetrachloride under continuous stirring. After continuous stirring for 1.0 h, react at 150 ° C for 48.0 h; roast the resulting mixed solution at 400 ° C for 5.0 h, then the product is filtered out, washed 3 times with deionized water, and vacuum-dried, pulverized and ground at room temperature to obtain a titanium phosphorus catalyst for polyester;

[0039] Synthesis of polyester:

[0040]333.3g purified terephthalic acid, 160g ethylene glycol and titanium phosphorus catalyst 0.13g (10ppm) are added in the 1L reactor, and carry out esterification, precondensation and final polycondensation successively under n...

Embodiment 2

[0042] Catalyst preparation:

[0043] Dissolve 16.5g of cetyltrimethylammonium bromide in 150ml of deionized water and stir vigorously until a uniform and stable solution is formed; then add phosphoric acid and titanium tetrachloride to the above mixed solution at a molar ratio of 0.9:1.1, first Add 8.82g (0.09mol) of phosphoric acid, and add 20.79g (0.11mol) of titanium tetrachloride under continuous stirring, after continuous stirring for 1.0h, react at 50°C for 72.0h; roast the resulting mixed solution at 500°C for 7.0 h, then the product is filtered out, washed 3 times with deionized water, and vacuum-dried, pulverized and ground at room temperature to obtain a titanium phosphorus catalyst for polyester;

[0044] Synthesis of polyester:

[0045] 333.3g purified terephthalic acid, 160g ethylene glycol and titanium phosphorus catalyst 0.06g (5ppm) are added in the 1L reactor, and carry out esterification, precondensation and final polycondensation successively under nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com