Novel filtering, washing and drying integrated device and process

A technology for washing, drying, and integrating devices. It is used in filtration and separation, drying chambers/containers, and drying solid materials. It can solve problems such as changing crystal morphology, blocking exhaust traps, and destroying material crystal forms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

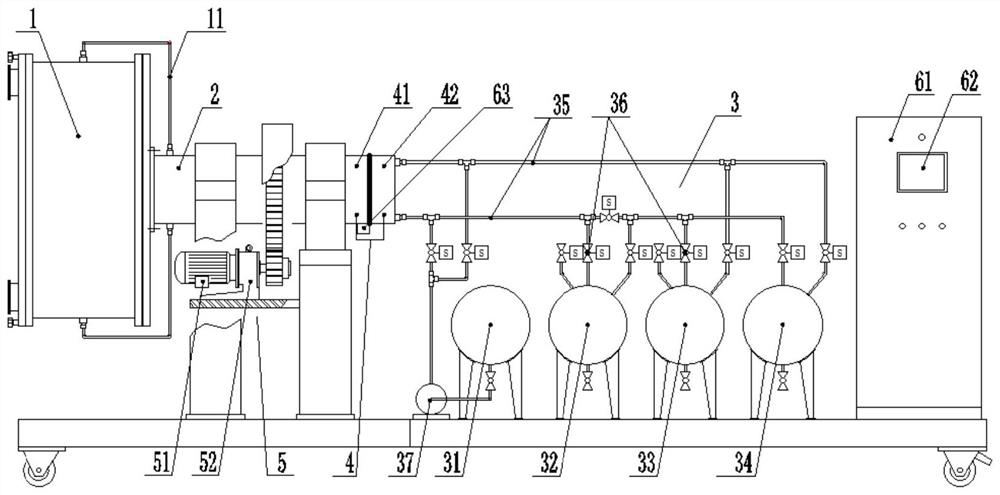

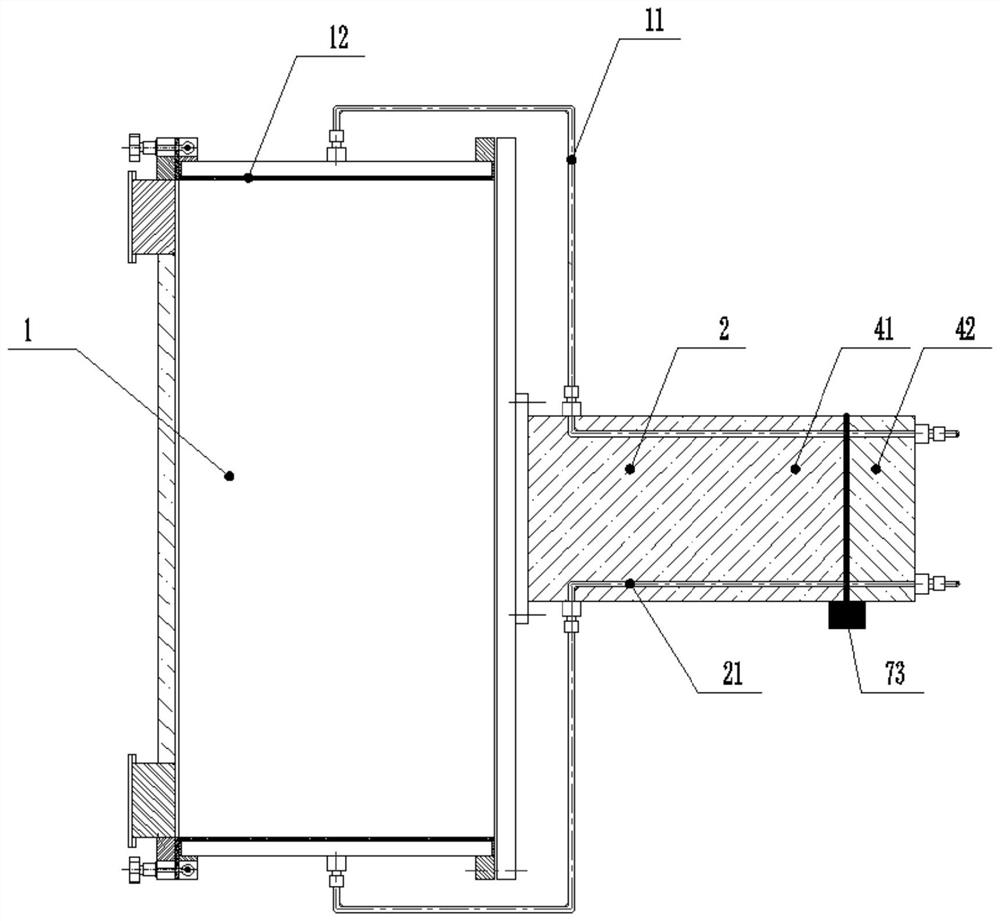

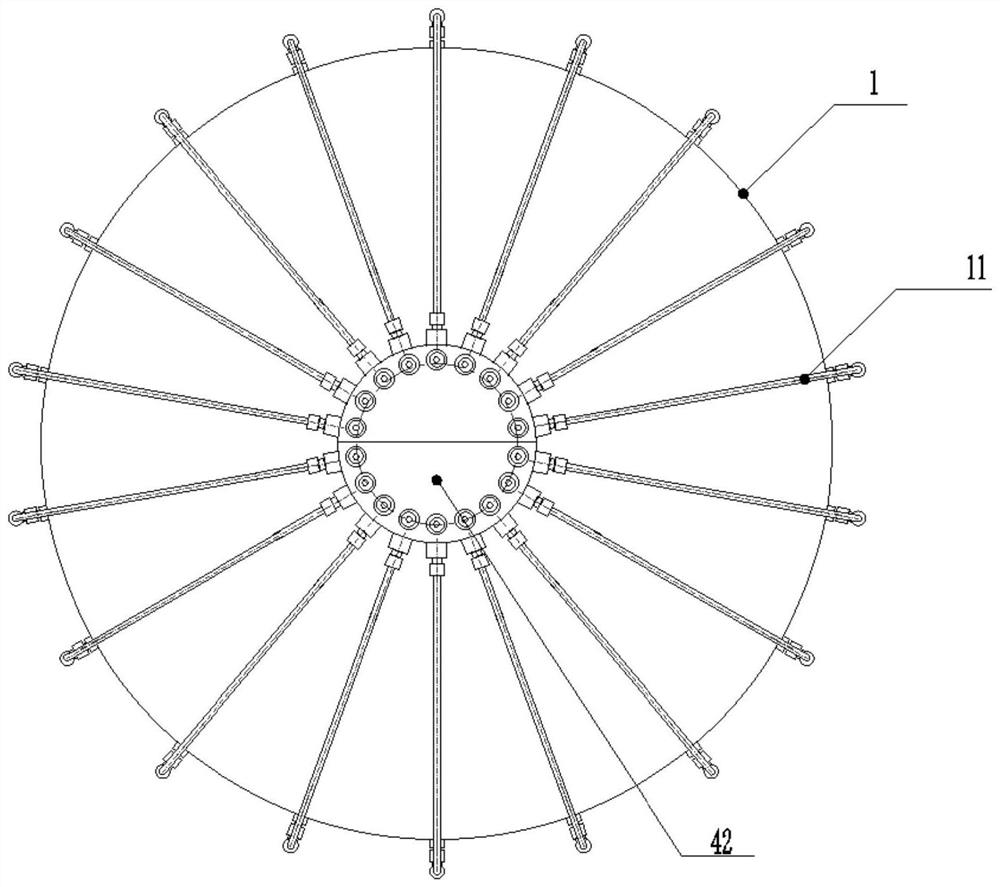

[0112] Such as Figure 1-5 A novel filter, washing and drying integrated device shown includes a drum 1, a rotating shaft 2, a gas-liquid distribution system 3, and a rotary joint 4; the drum 1 and the rotating shaft 2 are coaxially fixedly connected; the rotating shaft 2 It is connected with the gas-liquid distribution system 3 through the rotary joint 4;

[0113] The rotary joint 4 includes a dynamic ring joint 41 and a static ring joint 42; the static ring joint 42 is divided into an upper half and a lower half, and the upper and lower halves of the static ring joint 42 are independent of each other; The ring joint 41 is arranged on the rotating shaft 2 and rotates synchronously with the rotating shaft 2. The static ring joint 42 is arranged in the gas-liquid distribution system 3 and is relatively stationary with the gas-liquid distribution system 3. The moving ring joint 41 is arranged opposite to the static ring joint 42;

[0114] A gas-liquid channel 21 is arranged in...

Embodiment 2

[0121] Based on the filtration process of the novel filter washing and drying integrated device provided in embodiment 1, comprise the following steps:

[0122] S1-1: Open the valve 36 between the mother liquor tank 32 and the vacuum tank 33;

[0123] S1-2: Open the valve 36 between the lower half of the static ring joint 42 and the mother liquid tank 32;

[0124] S1-3: Close the remaining valves 36; pump the filtered mother liquor into the mother liquor tank 32 by vacuum, and solids are intercepted by the filter screen 12 in the drum 1 .

Embodiment 3

[0126] Based on the intermittent washing process of the novel filter washing and drying integrated device provided in embodiment 1, it may further comprise the steps:

[0127] S2-1: stop the rotation of the drum 1, and open the valve 36 between the static ring joint 42 and the booster pump 37;

[0128] S2-2: add detergent into the drum 1 through the booster pump 37, and control the material level to not exceed two-thirds of the vertical height of the drum 1;

[0129] S2-3: Control the rotation of the drum 1, the materials in the drum 1 are turned accordingly, and the materials fully contact with the detergent;

[0130] S2-4: Adjust the rotation speed and washing time of the drum 1 according to the material properties and washing requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com