Water pressure sealing method for top of silage in pit

A technology of silage and pit pond, which is applied in the preservation method of animal feed raw materials, animal feed, application and other directions, can solve the problem of uneven distribution of bacteria, and achieve the effect of improving the efficiency of repeated use and avoiding the antioxidant capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

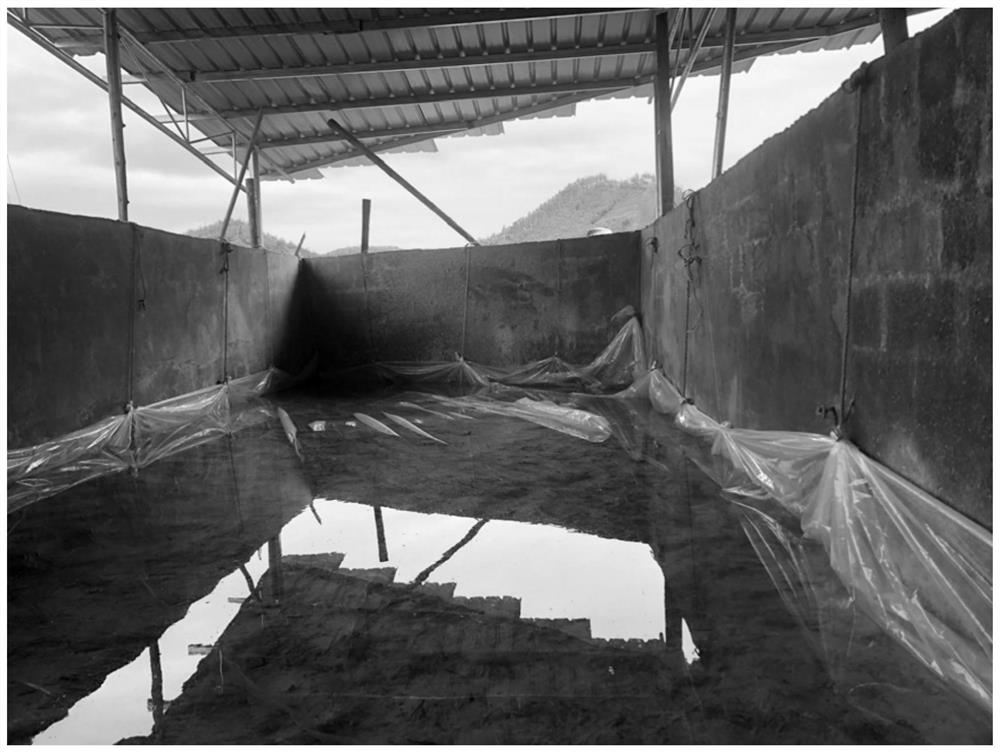

[0033] A method for hydraulically sealing the top of cellar silage, comprising the following steps:

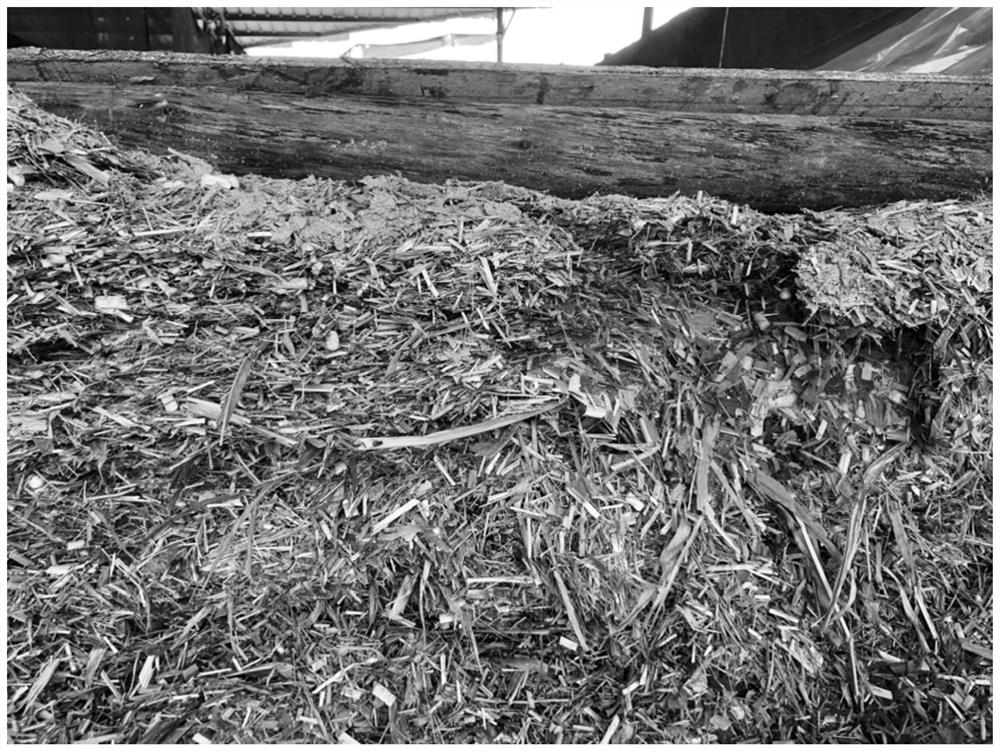

[0034] 1) Pre-preparation: Select local high-quality rice straw, chinensis, oat grass, and peanut shells as the bottom auxiliary materials. The auxiliary materials are laid on the bottom of the cellar with a thickness of 40-50 cm. Spray the probiotic liquid once, the dosage is 500ml of probiotic liquid per square, the water content is controlled at 20-30%, and then enter the next step to put the silage into the cellar;

[0035] The spraying of the probiotic liquid on the surface of the bottom auxiliary material is based on the principle of the atomization reaction between the fermented hot steam of the top layer of silage and natural gas. In the control of the moisture content of the raw material, if the moisture content of the silage is 75%-80%, add rice straw, Leymus chinensis, The proportions of dry matter raw materials such as peanut shells are 10%, 20%, and 30%, respectiv...

Embodiment 2

[0043] A method for hydraulically sealing the top of cellar silage, comprising the following steps:

[0044] 1) Pre-preparation: Select local high-quality straw, Leymus chinensis, oat grass, and peanut shells as the bottom auxiliary materials, which are laid on the bottom of the cellar with a thickness of 40-50 cm. Spray the probiotic liquid on the surface, and the auxiliary materials are evenly distributed every 10 cm. Spray the probiotic liquid once, the dosage is 500ml of probiotic liquid per square, the water content is controlled at 20-30%, and then enter the next step to put the silage into the cellar;

[0045] The spraying of the probiotic liquid on the surface of the auxiliary material is based on the principle of the atomization reaction between the top layer of silage fermentation steam and natural gas. In the control of raw material moisture, the super-moisture raw material needs to be mixed with dry matter raw materials. The weight ratio of the two depends on It de...

experiment example

[0053] Adopt the method of a kind of cellar pond silage top water pressure sealing of embodiment 1 and traditional silage method in the prior art to do comparative analysis:

[0054] 1. Preparatory work such as cellar facilities, processing machinery, personnel, and processing implementation plans before making silage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com