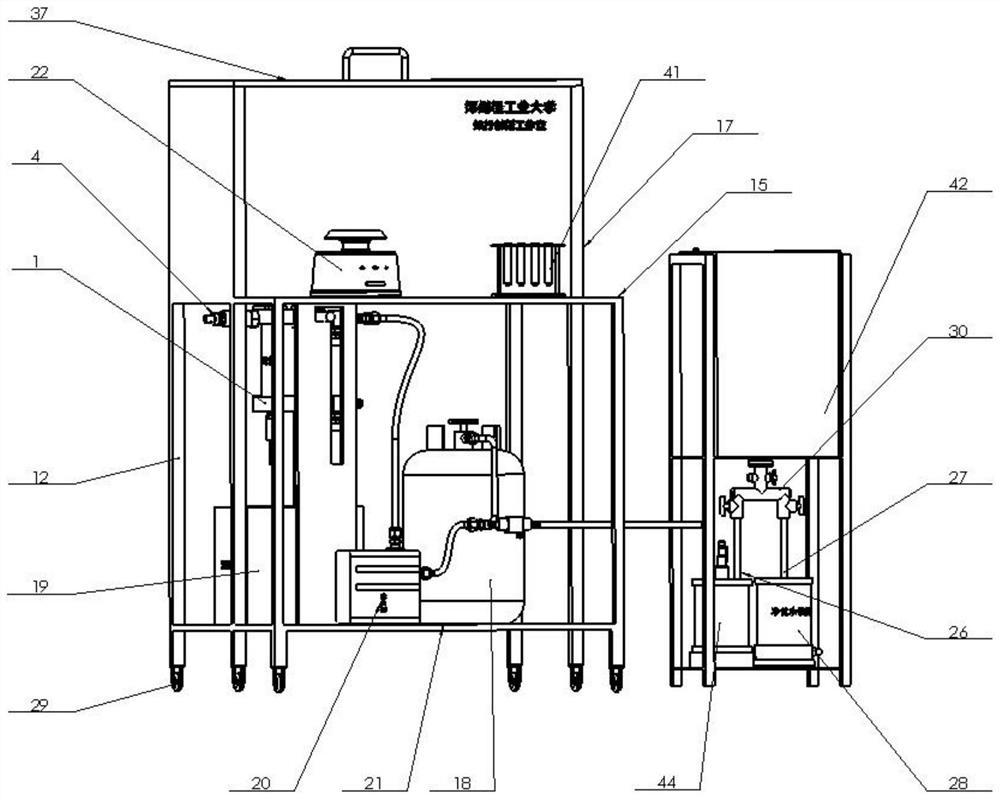

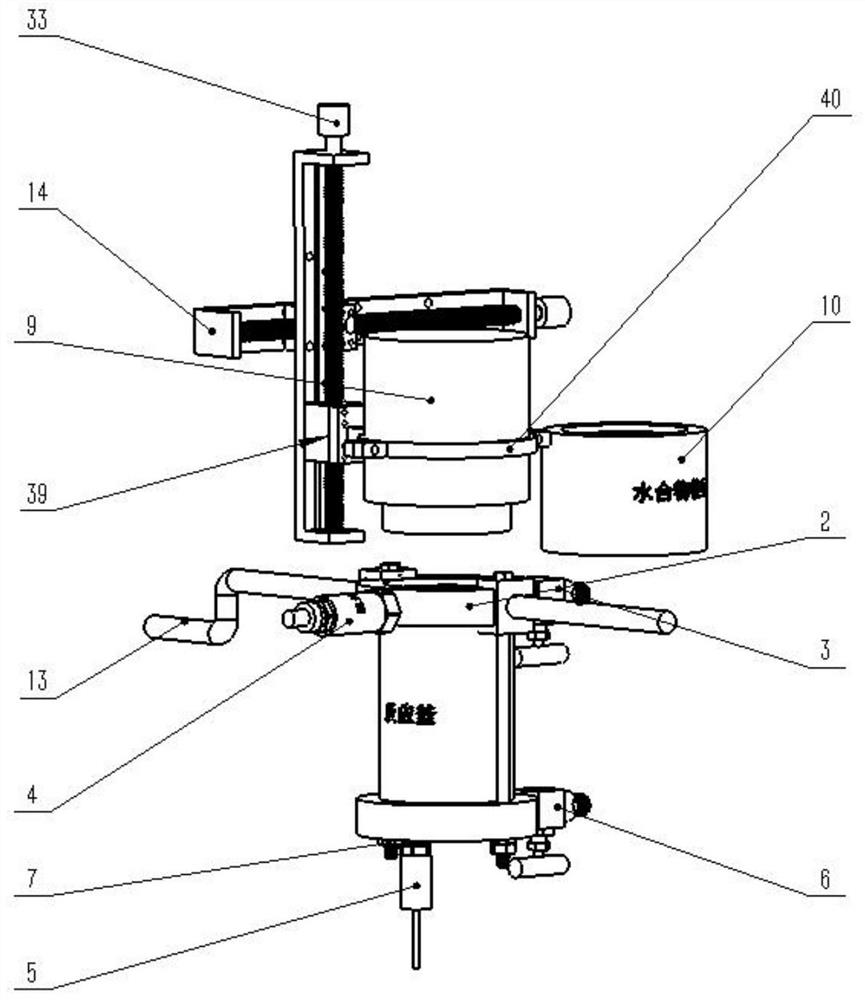

Rapid concentration and purification treatment device and method for hydrate sludge

A technology of concentration purification and treatment device, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, water treatment parameter control, etc. cumbersome issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

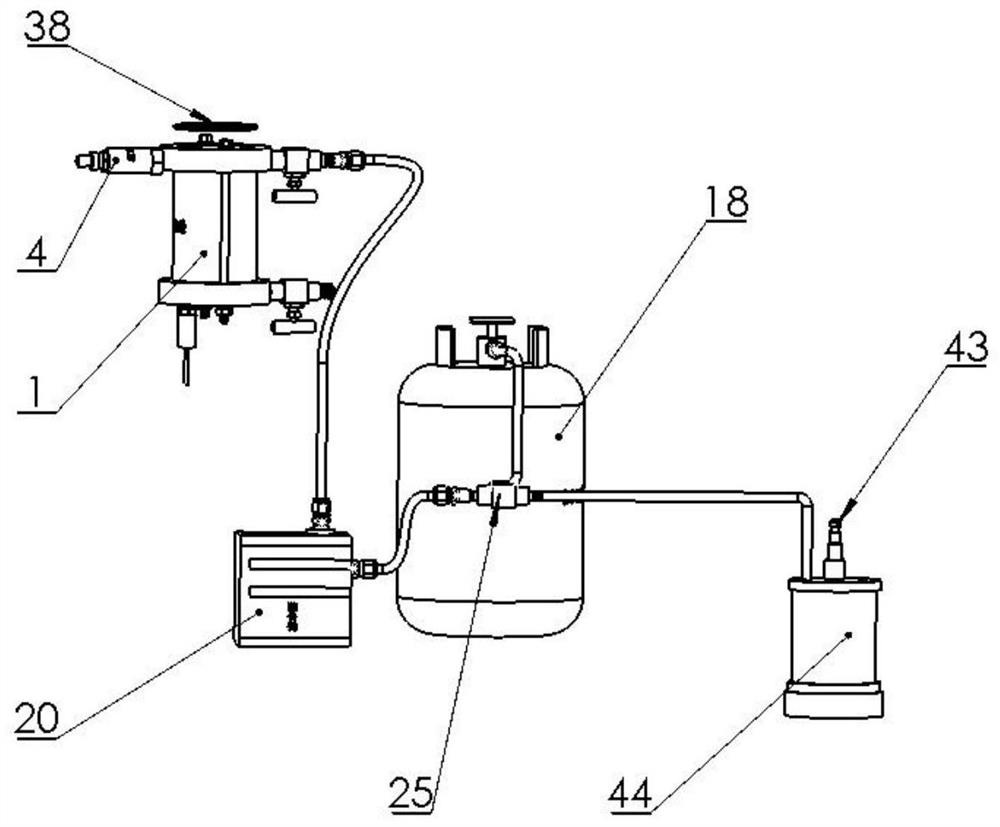

Method used

Image

Examples

Embodiment

[0035] The hydrate reaction in the reaction vessel of the device is affected by factors such as temperature, pressure, and reaction process; the hydrate dissociation reaction in the dissociation reactor of the device is affected by factors such as dissociation temperature and pressure, and the hydrate extraction and separation The process will produce a small amount of decomposition. The sludge rapid concentration test and the clean water discharge test are tested to simulate certain reaction environment parameters. The following is the implementation process of the patent test of the present invention:

[0036] (1) A rapid concentration and purification treatment device and method for hydrate sludge sludge rapid concentration test

[0037] Sludge rapid concentration test conditions: under the conditions of reactor temperature 8°C and reactor pressure 0.1Mpa, using quantitative HCFCR141b and sludge samples with a water content of about 97.81±0.01wt% from the sludge treatment pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com