Ultrahigh-pressure and high-temperature rock core sample transfer system and working process thereof

A sample transfer and ultra-high pressure technology, applied in the direction of reducing greenhouse gases, extracting undisturbed core devices, climate sustainability, etc., can solve the problems of not being able to provide a large pulling force, and achieve the effect of compact structure, convenient operation, and large driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

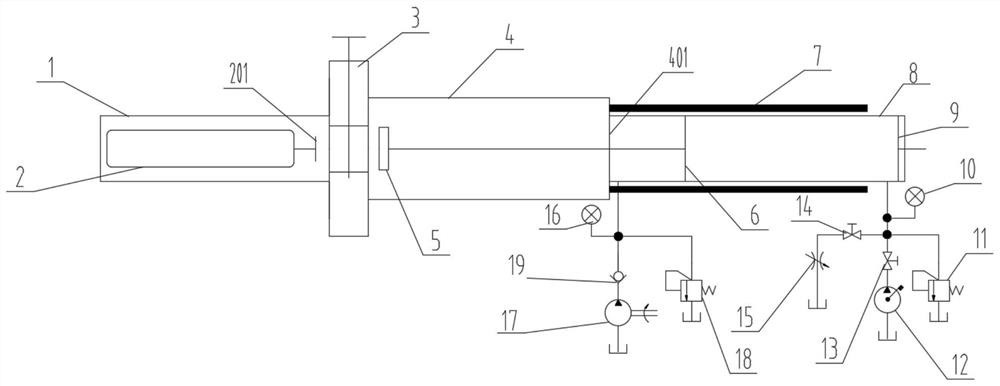

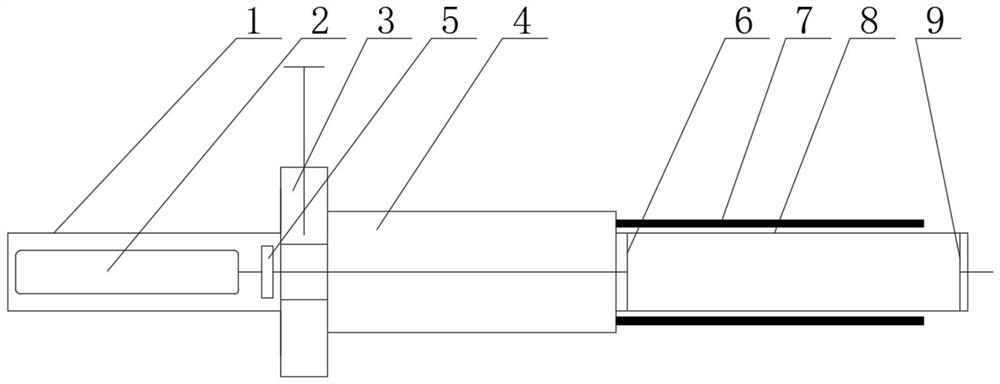

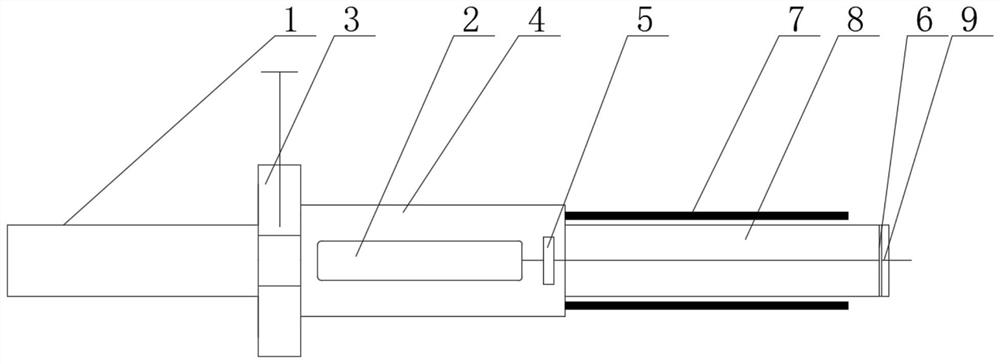

[0052] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0053] like Figure 1-Figure 15As shown, the ultra-high pressure and high temperature core sample transfer system of this embodiment includes a transfer cabin 4, which is a circular pressure-resistant cabin, one end of the transfer cabin 4 is sealed with a switch valve 3, and the other end of the transfer cabin 4 The oil cylinder 8 is sealed and connected. The piston rod 5 of the oil cylinder 8 passes through the hatch cover 401 of the transfer cabin 4 and enters the inside of the transfer cabin 4. The piston 6 of the oil cylinder 8 slides inside, and the tail of the oil cylinder 8 is fitted with a rotating The handle 9 and the outer wall of the oil cylinder 8 are equipped with a water-cooling jacket 7; the outer end of the switch valve 3 is sealed and connected with a coring cabin 1 or a preparation cabin 20, and there is a core 2 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com