High-throughput test method for storage of high-temperature alloy powder in positive-negative pressure protective environment

A high-temperature alloy and test method technology, applied in the field of powder superalloy, can solve the problems of high cost, low efficiency, air leakage, etc., and achieve the effects of high production efficiency, low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]The concrete steps of adopting the technical solution of the present invention are as follows:

[0036] Step 1. Prepare nickel-based superalloy powder with a composition of 16Cr-13Co-4W-4Ti-4Mo-0.8Nb-2Al-0.03C (mass fraction, %) by vacuum induction melting and argon atomization, and take 1 μm ~53μm particle size section for standby;

[0037] Step 2, making the superalloy powder be transported quickly under an argon protective atmosphere, and the transport time is 5 minutes;

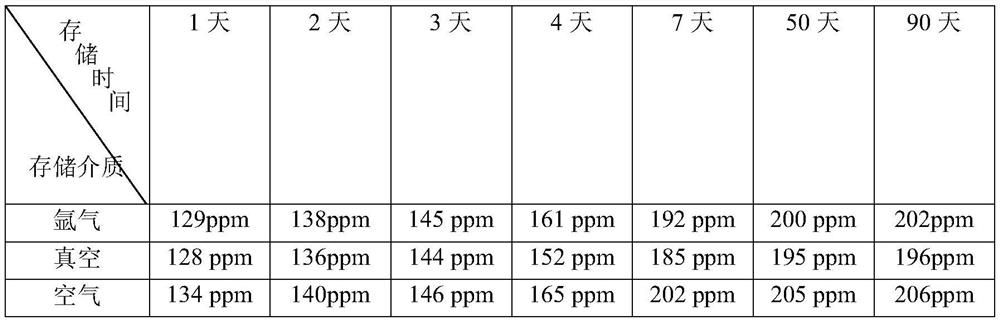

[0038] Step 3. Store environmental samples in a positive pressure protective atmosphere environment: pump out the residual gas in the soft packaging material container through a pipeline with a diameter of 20mm and a pumping time of 15s, and then fill the superalloy powder with the target composition and particle size through the pipeline. 150*100*20mm container, then fill it with argon gas through the pipeline, the inflation time is 20s, fill the container space after filling the powder and seal i...

Embodiment 2

[0044] The concrete steps of adopting the technical solution of the present invention are as follows:

[0045] Step 1. Prepare nickel-based superalloy powder with a composition of 16Cr-13Co-4W-4Ti-4Mo-0.8Nb-2Al-0.03C (mass fraction, %) by vacuum induction melting and argon atomization, and take 1 μm ~53μm particle size section for standby;

[0046] Step 2, making the superalloy powder be transported quickly under an argon protective atmosphere, and the transport time is 5 minutes;

[0047] Step 3. Store environmental samples in a positive pressure protective atmosphere environment: pump out the residual gas in the soft packaging material container through a pipeline with a diameter of 20mm and a pumping time of 15s, and then fill the superalloy powder with the target composition and particle size through the pipeline. 150*100*20mm container, then fill it with argon gas through the pipeline, the inflation time is 20s, fill the container space after filling the powder and seal ...

Embodiment 3

[0053] The concrete steps of adopting the technical solution of the present invention are as follows:

[0054] Step 1. Prepare nickel-based superalloy powder with a composition of 16Cr-13Co-4W-4Ti-4Mo-0.8Nb-2Al-0.03C (mass fraction, %) by vacuum induction melting and argon atomization, and take 1 μm ~53μm particle size section for standby;

[0055] Step 2, making the superalloy powder be transported quickly under an argon protective atmosphere, and the transport time is 5 minutes;

[0056] Step 3. Store environmental samples in a positive pressure protective atmosphere environment: pump out the residual gas in the soft packaging material container through a pipeline with a diameter of 20mm and a pumping time of 15s, and then fill the superalloy powder with the target composition and particle size through the pipeline. 150*100*20mm container, then fill it with argon gas through the pipeline, the inflation time is 20s, fill the container space after filling the powder and seal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com