an ag 2 cro 4 Preparation of @ag-modified carbon fluoride cathode materials

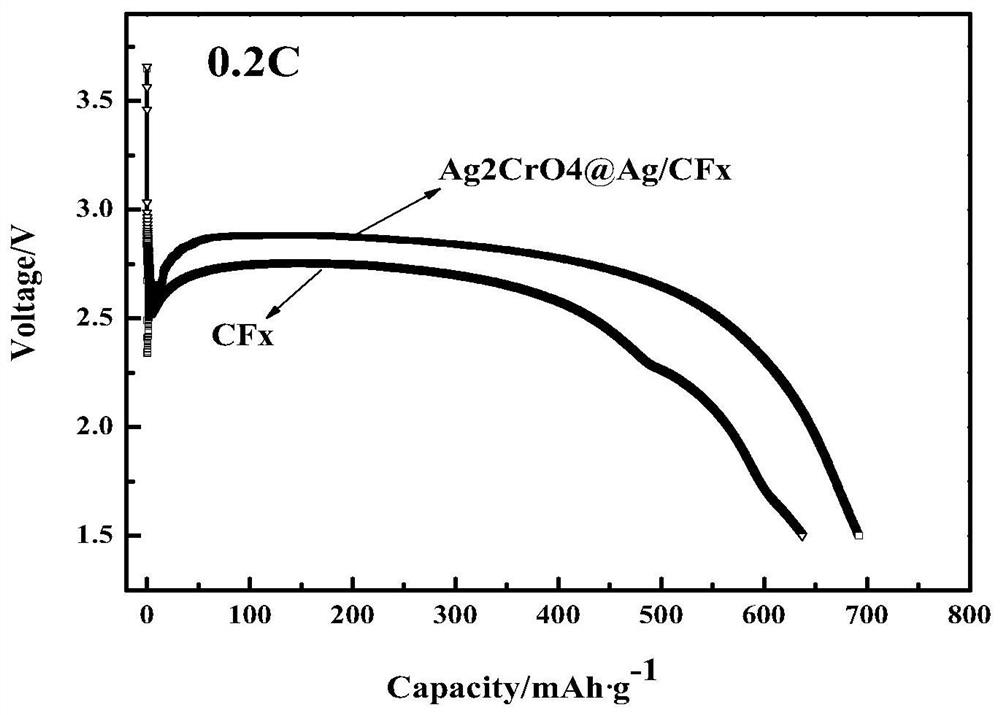

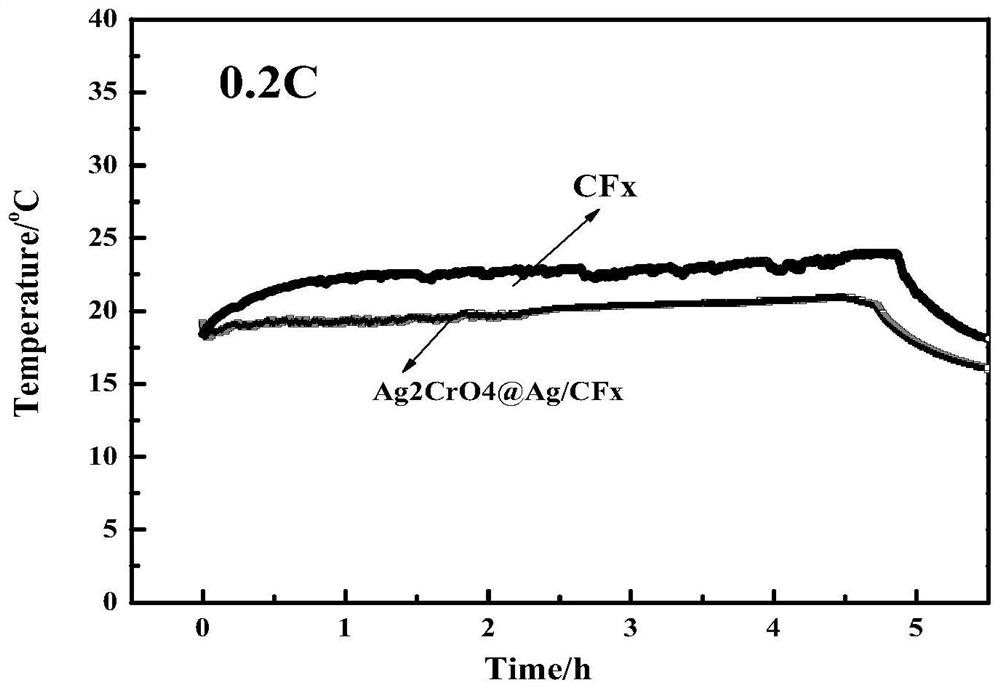

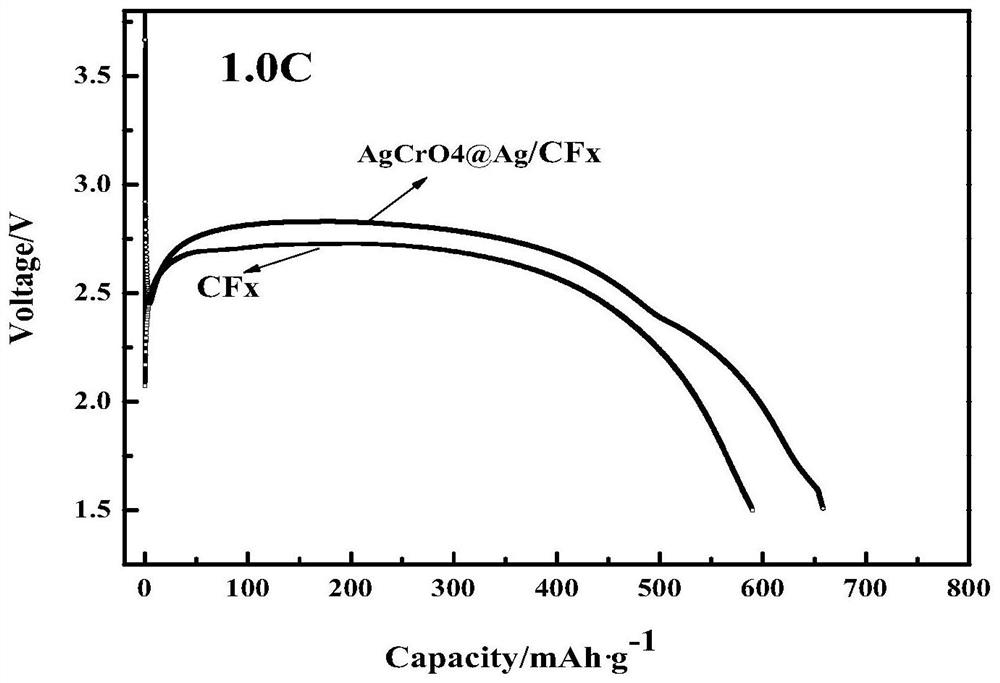

A positive electrode material, carbon fluoride technology, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problem of insignificant improvement effect, and achieve the effect of improving the voltage hysteresis problem, improving the voltage platform, and the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] AG 2 CRO 4 @AG modified method of preparing carbon -based pole material, including the following steps:

[0045] (1) Preparation of potassium chromate solution: K K 2 CRO 4 Scattered in the ionic water, stir 0.6h to uniform, and make potassium chromate solution with a mass concentration of 16.6 %;

[0046] (2) Preparation of carbonized decentralized liquid: According to fluoride: Water -free ethanol: ultra -pure water: polyethylene pyrirol = 1: 1: 1: 1 quality ratio, first uniform mixing of water -free ethanol and ultra -pure water uniformly Later, add carbonfluoride, slowly add polyethylene pyrirol, stir 1h to uniformly, and make fluoride decentralized liquid;

[0047] (3) Preparation of hybrid solution: Stir the potassium chromate solution and fluoride decentralized solution 0.6h to uniform to make the mixture;

[0048] (4) Preparation of silver solution: scattered silver nitrate in exfoliating water, stir 0.6h to uniform, and make silver solution with a mass concentratio...

Embodiment 2

[0053] AG 2 CRO 4 @AG modified method of preparing carbon -based pole material, including the following steps:

[0054] (1) Preparation of potassium chromate solution: K K 2 CRO 4 Scattered in the ion water, stir 0.7h to uniform, and make potassium chromate solution with a mass concentration of 25 %;

[0055] (2) Preparation of carbonized decentralized liquid: According to the quality ratio of fluoride: water -free ethanol: ultra -pure water: polyethylene pyrirol = 1: 1.5: 1.5: 1.5, first mix the water -free ethanol and ultra -pure water uniformly Later, add carbon fluoride, and slowly add polyethylene pyrirol, stir 1.1h to uniform, and make carbonized dispersal liquid;

[0056] (3) Preparation of hybrid solution: Stir the potassium chromate solution and fluoride decentralized solution by 0.7h to uniform to make the mixture;

[0057] (4) Preparation of silver solution: scattered silver nitrate in exfoliating water, stir 0.7h to uniform, and make silver solution with a mass concent...

Embodiment 3

[0063] AG 2 CRO 4 @AG modified method of preparing carbon -based pole material, including the following steps:

[0064] (1) Preparation of potassium chromate solution: K K 2 CRO 4 Scattered in the ion water, stir 0.8h to uniform, and make potassium chromate solution with a mass concentration of 20 %;

[0065] (2) Preparation of carbonized decentralized liquid: According to fluoride: Water -free ethanol: ultra -pure water: polyethylene pyrirol = 1: 1.1: 1.2: 1 quality ratio, first uniform mixing of water -free ethanol and ultra -pure water uniformly Later, add carbon fluoride, and slowly add polyethylene pyrirol, stir 1.2h to uniform, and make carbonized dispersal liquid;

[0066] (3) Preparation of hybrid solution: Stir the potassium chromate solution and fluoride decentralized solution 0.8h to uniform to make the mixture;

[0067] (4) Preparation of silver nitrate solution: scattered silver nitrate in de -ion water, stir 0.8h to uniform, and make silver solution with a mass conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com